ISSN: E 2347-226X, P 2319-9857

ISSN: E 2347-226X, P 2319-9857

Michael Tsatiris* and Kiriaki Kitikidou

Department of Forestry and Management of the Environment and Natural Resources, Democritus University of Thrace, Orestiada 68200, Greece

Received Date: 21/03/2018; Accepted Date: 06/04/2018; Published Date: 13/04/2018

Visit for more related articles at Research & Reviews: Journal of Agriculture and Allied Sciences

Biomass, as a renewable source of energy, could be converted into fuel in solid, liquid or gaseous form through a variety of modern technological production methods. Thermochemical processes and conversion technologies are briefly described in this paper with special emphasis on direct combustion and pyrolysis. The use of wood for energy purposes is becoming increasingly attractive in Greece and for the Mediterranean ecosystems as it can be upgraded into a more valuable and usable fuel.

Biomass, Thermochemical conversion technologies, Energy and biofuels generation, Mediterranean ecosystems

The potential offered by biomass for solving some of the world's energy problems is widely recognised. The energy in biomass may be realized either by direct use as in combustion, or by upgrading it into a more valuable and usable fuel. This upgrading may be by biological, chemical or thermal methods to give a solid, liquid or gaseous fuel [1]. In other words, the methods of energy biomass conversion are distinguished into biochemical (wet) and thermochemical (dry) ones. Thermochemical conversion processes mainly include direct combustion, pyrolysis, gasification, and liquefaction.

Generally, thermochemical processes have higher efficiencies than biochemical/biological processes in terms of the lower reaction time required (a few seconds or minutes for thermochemical processes vs. several days, weeks or even longer for biochemical/ biological processes and the superior ability to destroy most of the organic compounds. For example, lignin materials are typically considered to be non-fermentable and thus cannot be completely decomposed via biological approaches, whereas they are decomposable via thermochemical approaches. The stored energy within biomass could be released directly as heat via combustion/co-firing or could be transformed into solid (e.g., charcoal), liquid (e.g., biooils) or gaseous (e.g., synthetic gas and short for syngas) fuels via pyrolysis, liquefaction or gasification with various utilization purposes.

Biochemical methods rely upon the microbial conversion of biomass feedstocks to produce energy products. These methods are distinguished into [2,3]:

a. aerobic fermentation;

b. anaerobic fermentation;

c. alcoholic fermentation.

In this paper, thermochemical methods will be dealt with. Thermochemical processes involve reactions which depend on temperature for different oxidization conditions [3-8]. Use of heat takes place in order to change substances chemically to produce energy products. Feedstocks generally considered for thermochemical conversion are agricultural waste, wood and wood waste and energy crops. The main economic criteria for feedstocks in terms of their suitability for thermochemical processing are cost (which include production, collection and transport) and quantity available, both of which have a considerable influence on costs, whereas the main technical criteria are low moisture content and low ash content [1,9]. Thermochemical processing is flexible. Depending on conditions used (primarily the temperature reached, the oxygen availability and residence time at temperature), biomass can be altered very slightly or be completely changed. These three variables, for example, can define conditions for the various thermochemical processes but there is often little distinction among them and in fact there is a continuum of process conditions. Selection of treatment conditions permits a variety of outcomes of importance to the production of bioenergy products. The products differ in the proportions of solid, liquid or gaseous forms [6]. Thermochemical processing has attracted considerable attention from the variety of technologies available for converting biomass into more useful and valuable energy products. Thermochemical conversion technologies are distinguished into [1,6,10,11]:

Direct Combustion;

Pyrolysis;

Slow Pyrolysis;

Fast Pyrolysis;

Liquefaction;

Gasification

Each one of these technologies gives a different range of products. These are summarised in Table 1 and the characteristics of the technologies are described in Table 2. The basis of a fuel production system is that the feedstock is converted to a useful primary energy product in a sequence of operations: pretreatment, conversion and primary upgrading by simple physical processing such as gas scrubbing [1].

| Technology | Primary Product |

|---|---|

| Direct combustion | Heat |

| Pyrolysis generally | Solid char, liquid, gas |

| Slow pyrolysis | Solid char mostly |

| Fast pyrolysis | Liquid mostly |

| Liquefaction | Liquid |

| Gasification | Gas |

Source: (Beenackers and Bridgwater, 1989)

Table 1. Thermochemical conversion technologies and products.

| Pyrolysis | Liquefaction | Gasification | |||

|---|---|---|---|---|---|

| Slow | Fast | ||||

| Feedstock | Feed size | any | small | small | mixed-large |

| Moisture content | low | very low | very low | 50% max | |

| Parameters | Temperature, °C | 300-600 | 400-800 | 250-350 | 800-1100 |

| Pressure, bar | 0.1-1 | 1 | 100-200 | up to 30 | |

| Maximum throughput, t/h | 5 | 0.05 | 0.1 | 20 | |

| Products | Solid yield, % wt on dry feed | 30 | up to 20 | up to 25 | nil (ash) |

| Liquid yield, % wt on dry feed | up to 30 | up to 70 | up to 50 | up to 5 | |

| Gas yield, % wt on dry feed | up to 40 | up to 70 | 20 | 100 - 250 |

Source: (Beenackers and Bridgwater, 1989)

Table 2. Characteristics of thermochemical conversion technologies.

Thermochemical conversion denotes technologies that use elevated temperatures to convert the fixed carbon of the biomass materials by

(a) direct combustion to produce heat,

(b) pyrolysis to produce char, pyrolytic liquids and gas,

(c) liquefaction to produce heavy fuel oil or with upgrading, lighter boiling products used as distillates, light fuel oil or gasoline and

(d) gasification to produce low or intermediate calorific value gas. (The intermediate heating value gas can be subjected to indirect liquefaction to produce ammonia, methanol, Fisher-Tropsch liquids or upgraded to synthetic natural gas) [11].

In the discussion of thermochemical processing it is useful to consider first direct and complete combustion of biomass and then the thermochemical processing continuum to follow through various stages of incomplete combustion.

Direct combustion

Combustion or burning is a rapid combination of oxygen with a fuel, resulting in release of heat. The major combustible elements of lignocellulosic materials are carbon and hydrogen. Complete oxidation of these elements gives CO2, H2O and heat energy (exothermic reactions) as follows [4,5]:

C + O2 → CO2 + 7,840 Kcal kg-1 of C

H2 + ½O2 → H2O + 34,000 Kcal kg-1 of H2

In most cases, air is used as a source of oxygen and the associated nitrogen in the air must also enter the furnace. In order to insure complete combustion, somewhat more than the minimum theoretical, air must be supplied. Further, solid fuels, such as wood and coal, normally require larger amounts of excess air than do liquid or gaseous fuels because of problems in air-fuel mixing [6].

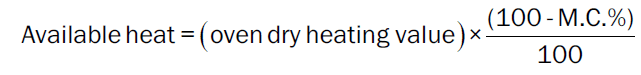

Water is a more serious problem in the combustion of green biomass materials (the moisture content of biomass fuels on a wet basis ranges from 20 to 50% or more). Evaporation of water requires energy which lowers the available heat of biomass according to the equation [4]:

Thus, for example, wood with an oven dry heating value of 4,500 Kcal kg-1 and a M.C. of 50% has an available heat of 2,250 Kcal kg-1. Despite the problems associated with direct combustion of biomass, it is currently the most direct and most widely used method for converting biomass into energy [6]. Today, direct combustion of biomass provides energy for cooking and heating to the majority of the rural population of the world [11,12]. In addition, biomass combustion is being used for electricity generation and cogeneration (simultaneous, sequential production of electricity and process heat) [13]. Biomass raw materials used for direct combustion are crop residues, fuelwood and wood processing residues [5,11,14]. Moreover, densified biomass fuels are used for this purpose [15-17]. Densified biomass fuel is a fuel made by compressing biomass to increase the density and to form the fuel into a specific shape such as briquettes or pellets.

Technical processes

Several firing methods exist to accomplish biomass combustion: grate firing, suspension firing, and fluidized bed combustion. The selection of the most appropriate firing method depends upon the size of the unit desired, the condition of the fuel available and the energy product to be produced (e.g. high-pressure steam). The grate - fired systems have been most widely used to date because they appear to be the most flexible combustors available. Fluidized bed combustors are rapidly emerging as an alternative to grate - fired biomass combustors [13].

Biomass combustors are commonly incorporated into boiler systems to produce steam. Most of the steam is converted directly to mechanical power or used for heat. Some boilers are incorporated into electrical plants to generate electricity. All such systems will be used increasingly in the future as biomass fuels are used more extensively.

Much of the wood fuel is burned in fireplaces and domestic stoves [4]. Conversion efficiencies are low, ranging from 5-20% in fireplaces and from 10-50% in stoves, whereas in modern combustion plants, conversion efficiency ranges from 60-80% [5,8], depending upon fuel moisture content, combustor design, and combustor operation [13].

In Greece, more than 50% of the harvested wood volume is used today as fuelwood [4]. Hardwoods, particularly Quercus comferta, Quercus coccifera and Fagus species are the main sources of fuel wood in northern Greece. Conifers such as Pinus halepensis, Pinus brutia and Abies chephalonica are the main sources of fuel woods in southern Greece. Rich in oleoresin old stumps of Pinus halepensis trees are still being collected and used for starting the fire in fireplaces, stoves and bakeries. In many villages of Greece, various species of phrygana have been used for heating old type furnaces for baking bread. Paliurus australis is the main species used for this purpose in northern Greece. A small number of steam generating plants continue to exist in Greece. Most of them are used by the forest products industries and are fuelled with wood manufacturing residues [4].

Pyrolysis

If thermochemical conversion of biomass is conducted in the absence of air or under air-starve conditions and at temperatures generally below 800°C, all three primary products char, pyrolytic liquids and gas can be recovered [1]. Rate of temperature change, residence time and composition of materials introduced into the reactor determine the nature of the products formed [4].

Slow pyrolysis (pyrolysis for carbonization)

The most common form of biomass pyrolysis is carbonization where charcoal becomes the primary product. Charcoal is produced under conditions of long residence time (hours to 7 days) at temperatures that range from 300 to 400°C, while restricting air supply [6]. The basic purpose of carbonization of biomass is its carbon enrichment by the removal of its liquid and gaseous components, a matter that contributes to the increment of its heating value. Charcoal is superior as a fuel compared to wood or agricultural residues and its production can be afforded in very simple systems. This is more energy-dense than its parent biomass forms and it is a smokeless fuel. The yield of wood into wood charcoal and the elementary composition of the last one depends on the carbonization temperature (Table 3) and time and on wood species and plant type [5].

| Carbonization Temperature |

Elementary composition (wt %) | Yield | ||

|---|---|---|---|---|

| (°C) | C | H | O | (% wt) |

| 200 | 52.3 | 6.3 | 41.4 | 91.8 |

| 300 | 73.2 | 4.9 | 21.9 | 51.4 |

| 400 | 82.7 | 3.8 | 13.5 | 37.8 |

| 500 | 89.6 | 3.1 | 6.7 | 33. 0 |

| 600 | 92.6 | 2.6 | 5.2 | 31.0 |

| 800 | 95.8 | 1.0 | 3.3 | 26.7 |

| 1,000 | 96.6 | 0.5 | 2.9 | 26.5 |

Source: (Philippou, 1981, 1986)

Table 3. Elementary composition and yield of wood charcoal in relation to the carbonization temperature.

The heart of the charcoal plant is the kiln and retort. Kiln technology (traditional charcoal - making), means all equipment producing charcoal as the sole product whereas retorts are essential elements of the industrial plant, capable of recovering and refining charcoal by - products in commercial grades and quantities [18].

Kilns as a means of traditional carbonization are internally heated and manually controlled. The three possibilities found are earth kilns and pits which are lowest in cost, brick kilns of intermediate cost, and steel kilns which are the most expensive. Steel kilns are further subdivided into portable and fixed types. Earth kilns and pits, even when operated efficiently, are slow burning and slow cooling and contaminate the charcoal with earth. However, where capital is limited or non-existent, they have real advantages [18,19].

Although cycle times for brick kilns are still around seven days, compared with two for steel kilns, the greater volume and much lower cost of brick kilns make them preferable except where portability is essential [18]. The normal raw material for kilns consists essentially of wood logs. In Greece, charcoal - making, mainly from firewood of oak and evergreen hardwoods takes place in traditional earth kilns and pits [8].

Charcoal retorts constitute elements of modern charcoal technology. These are externally heated and continuously operated plants for the carbonization of pile wood or wood logs. The term "retort technology" refers to carbonization of pile wood or wood logs reduced in size to a minimum length of 30 cm and not exceeding 18 cm in diameter [18]. Today, charcoal retorts are characterized by extensive automation operation, saving energy and labour costs. Among them, the French Sific process and some other processes derived from it such as the Lambiotte continuous carbonization process are considered as very successful technologies [20]. Carbonization time in the case of charcoal retorts is limited to some hours. The charcoal yield in charcoal kilns ranges from 15-30% wt whereas in modern plants (retort furnaces) from 30-40% wt [8]. Charcoal is used around the world as a premium solid fuel for domestic cooking, the refining of metals and the production of chemicals.

Fast pyrolysis

"Fast" or "flash" pyrolysis is a thermochemical technique for conversion of biomass materials to valuable gaseous and condensable hydrocarbon products which involves rapid heat-up of particulate biomass feeds [21]. It takes place under conditions of short residence time (in the order of seconds), at higher temperatures (400-800°C) than those employed for carbonization process and under oxygen-deficient or inert atmospheres [22,23]. "Fast" or "flash" pyrolysis is used to maximize either liquid (yield up to 70% wt) or gaseous products (yield up to 70% wt) according to the temperature employed [1].

High heating rates, of up to a claimed 1,000°C s-1 or even 10,000°C s-1, at temperatures below about 650°C and with rapid quenching, causes the liquid intermediate products of pyrolysis to condense before further reaction breaks down higher molecular weight species into gaseous products [1]. These high reaction rates also minimise char formation [21,22]. At higher maximum temperatures the major product is gas [1,23]. Pyrolysis at these high heating rates is known as "fast" or "flash" pyrolysis according to the heating rate and residence time, although the distinctions are blurred [1]. A variety of feedstocks (such as wood, energy crops, agricultural residues et al.) can be considered for "flash" pyrolysis processes as long as they meet the criteria of low ash content and low moisture content [24]. "Flash" pyrolysis is usually exerted in entrained beds (where indirect heating of biomass by gas phase heat transfer from hot gases is employed) or fluidized bed reactors (where hot inert solids - sand - provide indirectly the heat required for biomass pyrolysis reaction) [25].

Pyrolysis processes and fuels

By definition, pyrolysis of biomass produces solid, liquid and gaseous products. As a process, pyrolysis is flexible in the relative yields of these products. Charcoal, the solid product of pyrolysis, depending on its elementary composition (Table 3), has a heating value of about 5,500 to 8,000 Kcal kg-1. It can be used either for direct burning or converted further to liquid or gaseous fuels [6]. Antal and Richard [26] recently describe a new method for improving the yield of charcoal from biomass. Particularly, a 50 kg pilot plant (using a novel thermogravimetric analyser which operates at elevated pressure) developed in Hawaii Natural Energy Institute where the 45% wt yield of charcoal obtained with two very different feedstocks (Eucalyptus and Kiawe) after 150 minutes from cold start. Increasing in the pressure at which the charcoal process is conducted has been proved to be one of the most important parameters responsible of a high charcoal yield. The calorific value of the charcoal produced is uniformly high and the ash content is low.

O'Neil and Kovac [21] state that the most advanced biomass pyrolysis process in the United States in terms of scale and operational results is that of the Georgia Tech Research Institute (GTRI) Entrained Flow Pyrolysis Process which has achieved documented dry oil yields in excess of 55% wt and which promises to achieve yields of 60% wt in the near future. The Georgia Tech system is an updraft entrained bed reactor. Reactor temperatures have been varied from 425 - 550°C. Reactor times of less than one second to 3.5 seconds have been investigated.

The Waterloo Fast Pyrolysis Process (developed in Canada) is potentially the cheapest present method of converting biomass to an alternative fuel oil. This process is based on a fluidized bed reactor. Optimal conditions were determined to be, for poplar wood at least, 500 to 525°C, 0.4 to 0.6 seconds residence time. The oil yield by this method ranges from 75 - 80% wt. Further, the pyrolysis oil can also serve as a feedstock for the recovery of chemicals, for the production of a lignin product, or as a source of fermentable sugars [27].

Liquefaction

Liquefaction is another process which has been proposed to convert biomass to liquid fuel. It is low temperature (250- 350°C), high pressure (100 - 200 bars) thermochemical conversion in the liquid phase, usually with a high hydrogen partial pressure and also an alkaline catalyst (sodium carbonate) to enhance the rate of reaction and/or to improve the selectivity in product formation [1]. The oil yield from wood ranges from 45 - 58% wt and its heating value on a volume basis is about four times higher than that of wood [5].

Gasification

Gasification is the thermal decomposition of organic materials in the presence of controlled and limited amounts of air or oxygen to produce a combustible mixture of gases, often referred to as "producer gas" [4]. It takes place at high temperatures (800 - 1,100°C) and the yield in gas product ranges from 100 to 250 wt % [1]. To maximize the production of gaseous fuel product and to minimize that of the other two primary conversion products, char and liquids, sufficient residence time is required at conversion temperatures so that char and liquids undergo secondary reactions towards gaseous product [6]. When air is used, the produced gas contains mostly hydrogen, carbon monoxide and nitrogen. The mixture having a heat value from 900 to 1,800 Kcal m-3 is generally referred to as a low-calorie gas. When oxygen is used for gasification medium calorie gas with heating value as high as 3,500 Kcal m-3 is produced. Nitrogen dilution is eliminated so that the two major components of medium calorie gas are hydrogen and carbon monoxide. Lesser amounts of carbon dioxide and hydrocarbons are also produced in both cases.

The basic processes in gasification are similar to those in combustion except that complete oxidation of carbon and hydrogen to carbon dioxide and water, respectively, is avoided. The primary objective of the gasification processes is the quantitative conversion of carbonaceous materials to gaseous products that can be further used either as fuel or as raw material in the production of chemicals [4,8].

Biomass is not an exotic new source of energy whose use must await the creation of new technology. Biomass can be converted to energy in a number of ways. Direct combustion of biomass, is the age-old process with which man has supplied energy needs throughout his existence. A vast array of organic materials has been used. Still today, use of plant matter is considered a viable alternative to fossil fuels for generation of power. The technology for its use has been modernized and automated. Under some circumstances wood fuel has been competitive with oil and natural gas. As cost of the fossil fuels is increased, the use of wood fuel should become increasingly attractive. Pyrolysis, liquefaction and gasification technologies are being developed as alternatives to direct burning for the generation of energy from organic matter. These technologies have the added advantage of production of an improved fuel.

As an energy source, biomass has a number of advantages as compared to fossil fuels. It can be used as fuel in solid, liquid or gaseous form. It burns without significant toxic emissions. It is widely distributed geographically. It provides a convenient way of storing energy for future uses. Moreover, it is renewable. To biomass as a fuel it has been also assigned some disadvantages: It has a low heat value to weight ratio when compared with some fossil fuels. It has a substantial moisture content as it comes from the forest or crops. Geographical dispersion of biomass makes collection and transportation expensive. These disadvantages could be at least partially offset by using biomass on site or by converting it to higher energy solids (charcoal) or liquids (pyrolytic oil). In addition, technologies are being developed for densifying biomass into briquettes or pellets which can be easily and economically transported. Mediterranean ecosystems can still play a vital role for securing energy from their biomass, provided that their productivity is increased, and modern technology in converting biomass into energy applied.

The liquid biooil product from fast pyrolysis has the considerable advantage of being storable and transportable as well as the potential to supply a number of valuable chemicals, but there are many challenges facing fast pyrolysis that relate to technology, product and applications. The problems facing the sector include the following:

• Cost of biooil, which is 10 to 100% more than fossil fuel.

• Availability: there are limited supplies for testing.

• There is a lack of standards for use and distribution of biooil and inconsistent quality inhibits wider usage; considerable work is required to characterize and standardize these liquids and develop a wider range of energy applications.

• Biooil is incompatible with conventional fuels.

• Users are unfamiliar with this material.

• Dedicated fuel handling systems are needed.

• Pyrolysis as a technology does not enjoy a good image.

The most important issues that need to be addressed seem to be:

• Scale-up.

• Cost reduction.

• Improving product quality including setting norms and standards for producers and users.

• Environment health and safety issues in handling, transport and usage.

• Encouragement for developers to implement processes; and users to implement applications.

• Information dissemination.

While combustion, gasification and pyrolysis all need fairly dry feedstock materials, wet feedstock having moisture contents far over 50 wt.%, is often considered for conversion under hydrothermal conditions. The hydrothermal processes are still being investigated in research laboratories to proof the principles.