ISSN: 2319-9873

ISSN: 2319-9873

Department of Mechanical Engineering, Ramaiah Institute of Technology, Bangalore, India

Received Date: 30/10/2017; Accepted Date: 13/11/2017; Published Date: 22/11/2017

Visit for more related articles at Research & Reviews: Journal of Engineering and Technology

Glass fibre reinforced polymer is widely used in various applications for their improved properties. In order to further enhance the properties of GFRP laminates they can be combined with other material through the introduction of filler materials to get better properties. Development of advanced composites with improved properties is of utmost important, especially composite which are light in weight but with better tensile and flexural properties is the need of the hour. When the lamina plies are stacked at various angles, the lay-up is called a laminate. Continuous-fibre composites are normally laminated materials in which the individual layers, plies, or laminae are oriented in directions that will enhance the strength in the primary load direction. In our dissertation work we are adding graphene in various percentages to the GFRP composite laminate so as to increase its strength and mechanical properties. These properties will then be tested by carrying out tensile and flexural tests on the GFRP laminate according to the ASTM standards. For tensile test and flexural test ASTM values are found using D3039 and D7264 respectively. The effect of addition of graphene is studied by these tensile and flexural properties. This will help us to find out the ability of graphene powder to improve the mechanical properties of GFRP laminates.

Glass fibre, GFRP laminates, Graphene, Composites, Strength

In the present world the technology is being improved from decades. Even there is improvement and advancement in materials which are being produced for different application. When we look back, the conventional materials like metal was being used in every application and due to the advancement in the material science the conventional materials are being replaced by composite materials where polymer composite materials are taking a vital role. They have excellent properties due to their excellent properties they are being used in many applications. They have many advantages like high strength ratio, they have low density when compared with the conventional materials and the most important is that the fabrication process is very simple and it is very easy.

Fiber reinforced polymer (FRP), is one among the foremost necessary materials for engineering application because it has very high stiffness, it has high strength, it has good thermal and chemical properties and it is less expensive. Nowadays the Glass Fibers (GF) are used extremely as reinforcing with polymer composite due to their excellent properties like it is a light-weight material and it is less expensive due to this reasons it has been used in several applications. In Glass-fiber reinforced polymer (GFRP) Glass-fibers (GF) are arranged in a random way where it is flattened into sheet form (chopped strand mat), or it is in the form of woven into a fabric. The GF are made up of different type of glasses relying upon the fiber-glass usage. All the glasses contain silica / silicate, with different amount of magnesium, oxides of calcium and typically chemical element.

Graphene has recently given lot of attention because of its distinctive and better mechanical, electrical and thermal properties. Graphene is considered the perfect filler for epoxy resins due to its useful groups, like hydroxyl and even carboxyl groups, which gets into reaction with epoxy to obtain a better adhesion between epoxy and graphene.

In this project the GF is used as reinforcement in epoxy resin and graphene powder is used as filler material for the study of mechanical properties of GFRP composite. This dissertation work investigates the capability of Graphene powder to increase mechanical properties of GFRP laminates. Investigations are conducted with the three treatments along with the control. Treatments are by adding 1% of graphene powder to the GFRP and same is conducted to 3% and 5%. These treatments will be studied with respect to the tensile and flexural properties. The effect of addition of graphene in GFRP laminates is investigated and improvements in mechanical properties are noted.

Juan Chen evaluated effect of covalently grafting of GO sheets on to GF’s in improving interfacial properties of GFRP composites. GO sheets grafted GF were used to fabricate GFRP composites through vacuum molding technique [1]. The morphology structures of GO sheets were obtained through atomic force microscope, TEM and SEM. The TEM images showed wrinkling of sheets. It was evident from AFM images that the proper thickness of GO sheets on GF. SEM images relived that GF surface was immobilized by GO sheets. Inter laminar shear strength (ILSS) of GO grafted GF composite was enhanced compared with GFRP.

Dongyan L synthesized graphene/cellulose whiskers paper to fabricate epoxy resin sandwiched films and studied the properties. Graphene/cellulose nano whickers were prepared by ultra-sonication [2]. Epoxy resin sandwiched fabricated by dip coating method. The prepared films were subjects to tensile test and thermal analysis. XRD and SEM were used to investigate the cross sectional morphology of prepared composite film. XRD pattern showed presence of Gn/cellulose nano whickers in epoxy resin. From SEM images it was observed that better bonding between Gn/cellulose nano whicker in epoxy resin. Tensile strength of the sandwich film enhanced due to the presence of Gn/cellulose nano whickers. The glass transmission temperature of sandwiched films

Xiao-Jun Shen studied the improvement of cryogenic ILSS of GFRP. GFRP composite with varying wt fraction of GO was prepared [3]. SEM images for fractured surfaces of inter-laminar were obtained. Cryogenic ILSS of prepared composites was enhanced by an acceptable limit. But it was also observed that further increase in GO content decreases the ILSS because of weakening of GF and epoxy bonding which was predominantly agglomeration of GO. Even it was observed from the SEM images the fracture surfaces are smooth and uniform.

M Sudheer evaluated the mechanical wear properties of GFRP with PTW/ graphite hybrid fillers. Vacuum bag technique was used to produce the GFRP with PTW/graphite hybrid fillers with varying wt. fraction [4]. Prepared composites specimens were subjected to hardness, tensile, flexural and wear studies. Fractured surfaces were observed under SEM. Tensile strength of GFRP with PTW/graphite hybrid fillers was improved when compared with GFRP/PTW or GFRP/Graphite, Density and Rockwell hardness values of prepared composites increased with increase in wt fraction of PTW/graphite fillers [5]. Tensile test revealed failure of composites was due to splitting of fibers and plastic deformation of matrix. Pin on disk wear test showed decrease in wear loss with increase in normal load applied and sliding velocity [6]. Wear resistance of prepared composites containing both PTW and graphite was high. SEM images observed worn surface morphology and there were small grooves in the direction of sliding [7]. Wear debris showed that adhesive and fatigue wear took place which corresponds to poor typological performances.

Manufacturing of a composite material is to combine the polymeric resin system with the fiber reinforcement. Since the orientation of the fibers is critical to the end properties of the composite, manufacturing process is utmost important to align the fibers in desired direction [8]. A good manufacturing process will produce a higher, uniform fiber volume fraction along with a higher production of a large volume of parts economically and have repeatable dimensional tolerances.

Objective of the Project

• Investigating the ability of Graphene powder (filler material) to enhance the mechanical properties of GFRP composite.

• Investigations are carried out by adding 1% of graphene powder to the GFRP and same is conducted to 3% and 5%.

• These will be studied with respect to the mechanical properties.

• The effect of addition of graphene in GFRP laminates is investigated and improvements in mechanical properties are noted.

The following methodology is used in the present work

• Fabrication of GFRP test specimens.

• Specimens to carry out tests are fabricated by using Hand lay-up process. Different types of GFRP laminates of composites are prepared for the investigation. The fabrication is carried out by varying percentages of graphene addition i.e., 1%, 3% and 5%.

• The test specimens are tested for tensile and flexural test, using UTM.

Fabrication of GFRP Test Specimens

By using hand layup process the composite laminates were fabricated at room temperature. To avoid voids in the material, to maintain homogeneity and to maintain uniform thickness a proper care was taken during the fabrication of laminates [9].

Hand lay-up process

Hand lay-up technique was used for the fabrication of the specimens as per the steps articulated in Figure 1. Before lay-up the TEFLON mould was applied with a mould releasing agents (Paraffin was) to ensure smooth removal of the laminate from the mould and to avoid its adhesion to the mould [10]. The fiber: matrix ratio of 65:35 weight percentage was maintained for each specimens. A brush was used to impregnate the fibers with the resin.

Fabrication process of GFRP

In market bi-woven cloths are available in the standard thickness of 0.3 mm thickness; later according to the requirement of the size and shape the bi-woven cloths are cut. Those cut cloths of 7 layers are taken and placed one above the other to form layers such that the thickness of 2 mm as per ASTM standards was maintained. Epoxy resin is hand laid over each layer of the sheets.

The process of polymerization is called “curing” and curing can be controlled with temperature control and regulation and even with the choice of resin and hardener compounds. This process can take minutes and it can also extend up to hours. There are some formulation benefits from heating during the curing period; however others simply require time and sufficient temperature. Vacuuming is done to remove the air traps between the layers. Later room curing is done [11]. After vacuuming and room curing the material is to be post cured by placing in an Owen at a temperature of 1000ºC up to 2 hrs. After the curing process those cured materials are cut into the required size and shape as per ASTM standards as per the steps articulated in Figure 2.

Cutting of Fabricated GFRP

High precession power Hacksaw is used for cutting of fabricated GFRP according to the desired dimension from the ASTM standards. Power hacksaw it is also called as an electric hacksaw. It is powered by a motor which is run by electricity. Some powered hacksaws are stationary and some are portable. Usually the stationary machine will have different mechanism; some have pump to circulate the coolant and to prevent the saw blade from overheating and other has lift up saw blade while it is in the return stroke and Usually, those blades can be mounted with the teeth facing toward or away from the handle, results in cutting action on either of the push or pull stroke.

Here the stationary power hacksaw is used. The fabricated GFRP are held with the support of bench vice, hacksaw blades should be set to be facing forwards over the fabricated GFRP. The precession cut is made according to the dimension from the ASTM standard.

Mechanical Testing of Composite Laminates

Mechanical testing of prepared GFRP laminates are tested using computerized Universal Testing Machine. It has got 2 crossheads; one is used for adjusting the length of the specimen and the other is used to apply tensile force to test specimen [12]. There are two types, they are powered by hydraulics and the other one is powered by electro-magnetically.

Mechanical properties such as ultimate tensile strength (UTS), Young’s modulus Flexural strength (FS), Flexural modulus of glass fibre reinforced epoxy composites are computed from the test conducted using universal testing machine (UTM) in accordance to ASTM standards for specimen preparation [13]. UTM specifications are shown in Table 1.

Table 1. Specifications of universal testing machine.

| Parameter | Specification |

|---|---|

| Capacity | 10 tones |

| Load frame | Mild steel C channel with double ball screw mechanism pre-loaded ball screw with zero backlash covered with below |

| Mounting | Free standing |

| Load range | 1 kg – 1000 kg using 1 ton load cell 1 kg – 1000 kg using 10 ton load cell |

| Length measurement | Rotary encoder mounted on to the screw rod |

| Length resolution | 0.01mm |

| Cross head speed | 0.1 to 100 mm/min |

| Controls | Emergency off, up and down key |

| Input power | 220V± 10% VAC, 50 HZ, 1500 VA |

| Net weight | 225 kg |

| Grippers | Tensile, compression, three point bending |

| Length accuracy | ± 0.1 mm |

Tensile testing of composites

Here 6 tensile specimens were used for tensile testing with varying percentages. In any laminate, if the tensile force is along the fibre direction it is assumed to have higher axial strength. The overall length of the tensile test specimen is maintained at 250 mm and width of 25 mm with thickness of 2 mm [14]. The tensile test specimens of GFRP are as shown in figure. The tensile specimen was held in a universal testing machine by wedge action grips as show in figure and pulled at recommended cross head speed of 4 mm/min which corresponds to a strain rate of 0.2%/sec.

For tensile test specimen the dimensions are obtained from ASTM D3039 and for flexural test specimen they are obtained from ASTM D7264, is shown in Figure 3.

Flexural testing of composites (3 point bending test)

Three point bend test was used to test the flexural specimens which is commonly accepted. To determine the fracture toughness/shear strength the three points bending test was carried out. Even to find out the mechanical characterization it was been used. A total of 6 specimens with dimensions of 140 × 25 × 2 mm were fabricated [15]. The GFRP Flexural test laminates were cut from panel using diamond saw, to ensure that no stresses are induced into the laminates, there by not affecting the flexural test properties (Figure 4). The laminates are prepared as per ASTM standards D7264 a flexural test of central loading was provided with constant loading rate of 2 mm/min. Few specimens were evaluated up to elastic limit and few until failure was encountered [16].

Formulae Used

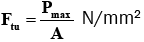

Ultimate tensile strength (UTS)

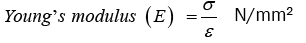

The UTS (σ) and the Young’s modulus are calculated using the formula 5.1 and formula 5.2 respectively (Figure 5).

(5.1)

(5.1)

Where ‘P’ is the maximum load in Newton’s

‘A” is the area in mm2

Strain (ε) = change in length / original length

(5.2)

(5.2)

Flexural strength

Flexural strength, strain and flexural modulus of the composites are determined using the formula 5.3,5,4 and 5.5 respectively (Figure 6)

(5.3)

(5.3)

b) Strain  (5.4)

(5.4)

c) Flexural modulus  (5.5)

(5.5)

Where, ‘P’ is the peak load in N

‘L’ is the span length in mm

‘b' is the width of specimen in mm

‘d’ is the thickness of specimen in mm

‘D’ is the Deflection from no load condition in mm

Tensile Test Results of GFRP Composites

The tensile test was carried out on GFRP using ASTM D3039 standards. Tensile strength of laminate was obtained and the test results are shown in Table 2. The following table was noted with original gauge dimension and its corresponding change in length is noted respectively and thereby the percentage of elongation is calculated in Figures 7A-7C.

Table 2. Tensile test results for GFRP laminates with graphene.

| % Graphene | Specimen No | Percentage Elongation (%) |

Peak Load (N) |

UTS (N/mm2) |

|---|---|---|---|---|

| 1% Graphene | 1 | 5.22 | 16890 | 337.8 |

| 2 | 6.02 | 18450 | 369 | |

| 3% Graphene | 1 | 2.04 | 20400 | 408 |

| 2 | 2.94 | 20560 | 411.2 | |

| 5% Graphene | 1 | 3.02 | 21930 | 438.6 |

| 2 | 2.22 | 22500 | 450 |

Tensile Test Discussion

After conducting the tensile test on GFRP composite it was found from Figure 8 that the tensile strength of GFRP is linearly increasing. The comparison is made on the basis of increase in percentage i.e., graphene 1%, 3% and 5% graphene. In this condition the strength is increasing linearly.

Flexural Test Results of GFRP Composites

To find out flexural strength of laminates flexural test was carried out. This test was carried as per ASTM standards D7264. Where three point bend test was carried to obtain the flexural strength of GFRP composite (Figure 9). These tests on GFRP composite were carried out till failure of the specimen was noted. The results are shown in Table 3.

Table 3. Flexural test results for GFRP laminates with graphene.

| Sl No | Specimen No | Peak Load (N) |

Max Displacement (mm) |

Flexural Strength (N/ mm2) |

|---|---|---|---|---|

| 1) 1% Graphene | 1 | 171 | 14.4 | 256.5 |

| 2 | 194 | 14.2 | 291 | |

| 2) 3% Graphene | 1 | 215 | 14.39 | 325.5 |

| 2 | 216 | 13.32 | 324 | |

| 3) 5% Graphene | 1 | 221 | 13.4 | 333 |

| 2 | 222 | 15.71 | 331.5 |

Flexural Test Discussion

After conducting the flexural test on GFRP composite it was found from Table 3 that the flexural strength of GFRP is linearly increasing. The comparison is made on the basis of increase in percentage of graphene. Here also it was increasing linearly from 1% to 5% graphene. Even it was found out that the flexural strength of 5% graphene was found to be the highest among these.

Flexural Testing of GFRP Composite

From Figure 10 it was observed that the toper layer where the vertical centre load is acting at that place the layer undergoes compression and the opposite layer undergoes expansion. It was also observed that the fracture occurs from the outer layer which is subjected to expansion.

Fiber reinforced composite are one of the booming materials in aerospace, automotive, marine, construction and building Industries. In which Glass fibers are taking a vital role in fiber reinforced composite because of its good mechanical properties. In this chapter the conclusions are made by the result obtained by investigation of GFRP composite. Investigations are carried out by tensile and flexural testing.

• From tensile test investigation, it was found that the Tensile strength increases with the increase in the percentage of graphene added to the GFRP laminates, it increases linearly from 1% to 5%.

• Three point bending test results showed that Flexural strength increased with the percentage of added graphene increased from 1% to 5% graphene to the GFRP laminates.

• This dissertation work investigates the ability of Graphene powder to improve the mechanical properties of GFRP laminates.

The main aim of this work was to investigate the mechanical properties of GFRP laminates by adding 1% of graphene and the same is conducted for 3% and 5% of graphene. Finally it was found that with the addition of graphene the tensile and flexural strength of the GFRP laminate were increased with the increasing percentage of graphene in the laminates of GFRP.

The present work included the addition of graphene to the GFRP Laminate. Further the GFRP Laminate with 5% graphene produced significant improvement in tensile and flexural strength. However, the following scope for future work can be looked into and explored in depth.

• Addition of CNT into GFRP laminates and properties can be reviewed.

• Properties of the same can be reviewed with Kevlar based laminates.

• Further, the performance of GFRP sandwich panels can be tested with graphene as the filler material.

• Low velocity impact tests can be carried out on the GFRP plates to review their impact strength with addition of graphene.

• Compression studies can be carried out on graphene added GFRP laminates.

Sandwich based mechanical testing can be carried out by adding nano-fillers.