Page 62

Notes:

conferenceseries

.com

Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

Advanced poly dimethylsiloxane-urea copolymer based masterbatches with multiple functionality

Hans-J. Radusch

1

, Matthias Huebner

2

, Friedhelm Roeber

2

, André Wutzler

3

and

Nadine Poenisch

4

1

MLU Halle, Germany

2

DAW Nerchau, Germany

3

PSM Merseburg, Germany

4

KUZ Leipzig, Germany

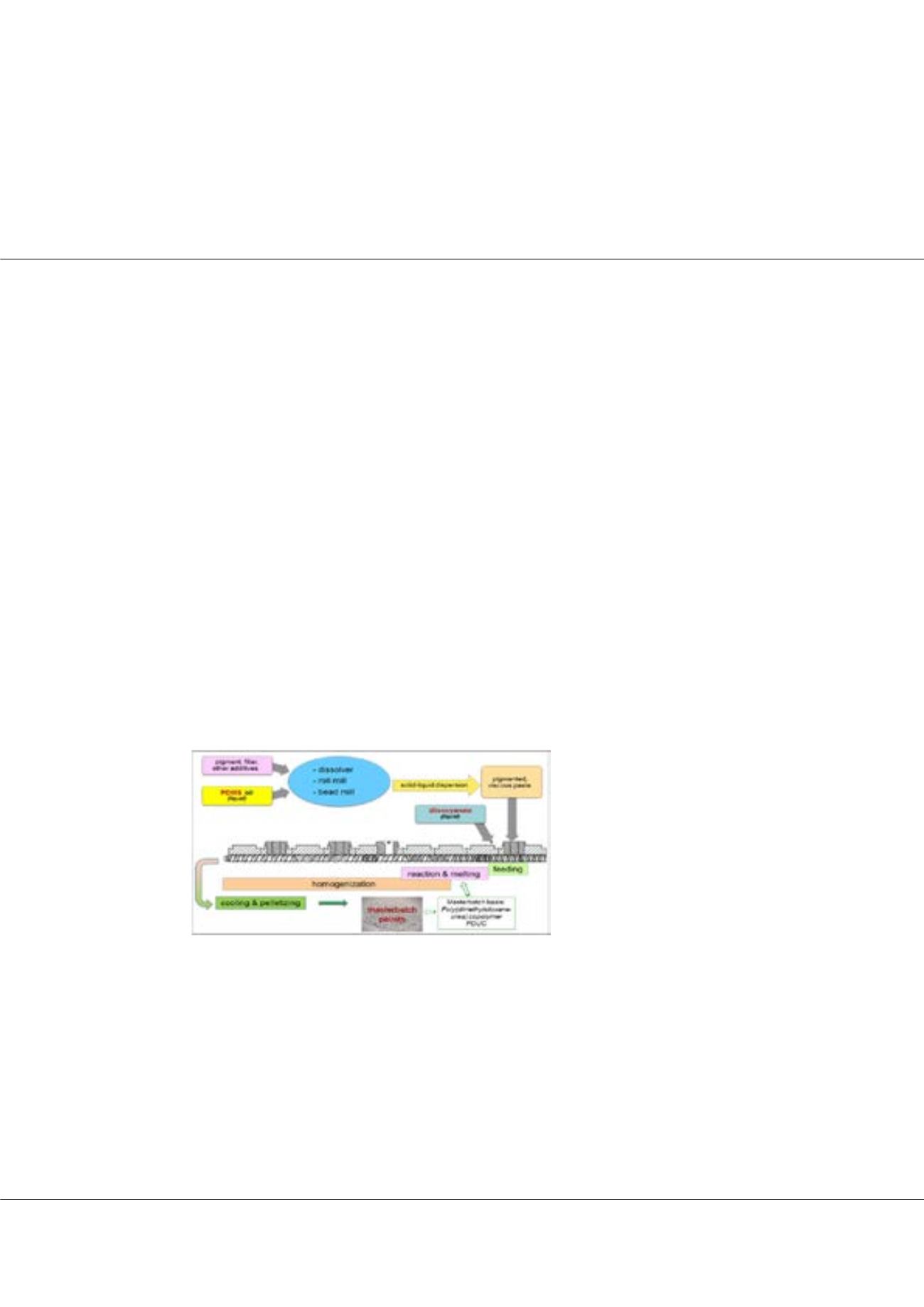

O

ptical and esthetic modification is a basic need for polymer application in all technical and consumer fields. Colorants are used

in broad volume to satisfy the demand of costumers for that purpose. Organic or inorganic colorants are included in a carrier

polymer, which should help to dose the colorant precisely, to mix it homogeneously, to be compatible with the matrix, and it should

not influence the mechanical and rheological properties unfavourably. A colorant masterbatch on the basis of polydimethylsiloxane-

polyurea copolymer (PDUC) was developed. The masterbatch was generated by an innovative processing technology coupling a

pre-dispersion step and a fluid component based reactive extrusion step. A specific twin-screw extruder with feeding units is used

for the liquid initial components polydimethylsiloxane (PDMS) including the pre-dispersed colorant as well as the diisocyanate.

The precise stoichiometric ratio of the components as well as the optimization of residence time of the polymer in the extruder in

concern to the reaction time of the components allowed the generation of the PDUC based masterbatch. Different isocyanates and

aminopropyl terminated PDMS were used. A higher number of thermoplastics was involved into the investigation of the suitability

of the generated masterbatches. Beside the nearly universal applicability of the masterbatch, the improvement of processibility -

expressed by lowering of the viscosity, reduction of energy consume of the extruder or reduction of rejection forces at injection

molding - could be demonstrated. Thus, the masterbatch proves to be not only an effective colorant, but also an internal lubricant.

The good dispersion of the pigment particles was demonstrated by optical microscopy. Stress-strain measurements proved that no

significant negative influence of the new masterbatch in concentrations < 5 % on the mechanical properties of the investigated

thermoplastics could be observed. Furthermore could be shown that the masterbatch composition and manufacturing technology is

suitable as carrier for the inclusion of nano-particles into polymer materials.

Biography

Hans-Joachim Radusch is an expert in the field of the development of new polymer materials by blend and composite technologies under special consideration

of nanofillers and nature based polymers. He graduated with a PhD thesis in the field of polymer processing in 1975. After his PhD study, he was employed in

industry before he returned to Technical University Merseburg, where he habilititated with a thesis on polymer blends in 1985. 1989 he became a professor of

Polymer Materials Technology at the Technical University Merseburg, and 1994 he was called for a full professorship for Polymer Technology at the Martin Luther

University Halle-Wittenberg. Since more than 30 years he has a lot of experience in modification of polymers by reactive polymer processing as well as polymer

materials characterization.

hans-joachim.radusch@iw.uni-halle.deHans-J. Radusch et al., Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-005

Figure1:

Masterbatch generation by coupled

dissolver pre-dispersion and reactive twin-

screw mixing technology.