ISSN: E 2347-226X, P 2319-9857

ISSN: E 2347-226X, P 2319-9857

1Department of Statistics, Maharaja’s College, Ernakulam, Kerala

2Department of Dairy Technology, CDST, KVASU, Thrissur, Kerala

Received date: 26/11/2021; Accepted date: 10/12/2021; Published date: 30/12/2021

Visit for more related articles at Research & Reviews: Journal of Agriculture and Allied Sciences

Burfi was prepared by mixing khoa with 30% sugar by weight and incorporating roasted foxtail millet powder. Trials were done by adding foxtail millet powder at 3 different levels viz, 5%, 10% and 15%. Foxtail millet at 10% was selected for the level of addition based on the result of sensory analysis. The proximate analysis of foxtail millet burfi revealed that it contains 89.10% total solids, 15.5% fat, 18.38% protein, 11.30 % moisture content, 2.85% ash 0.89% dietary fibre and 0.315% acidity. The scores of burfi for overall acceptability and flavour obtained for foxtail millet added at 10% was much higher than other treatments. From the results of the present study, it can be concluded that roasted foxtail millet powder up to a level of 10% can be incorporated in burfi which improves the nutritional quality and reduces the cost of production.

Burfi, Foxtail millet, Nutrition, traditional dairy product

Dairying in India is an integral part of the total farming system. A symbiotic relationship exists between agriculture and dairy farming. India is the leading milk producing country in the world, accounting for 19% of the global market share. The per capita availability of milk increased to 394 grams per day (NDDB, 2019). About 50–55% of milk produced is converted into a variety of Indian milk products by the traditional sector.

Khoa is a heat desiccated milk product used as a base material for a large variety of sweetmeats like burfi, peda, gulabjamun, etc. Burfi is a popular milk based confection. Sugar is added in different proportions along with other ingredients according to the demand of consumers. Burfi is indisputable product having economic importance especially in rural part of India as it provides good means for converting surplus milk into value added products. It has unique importance in market as it is liked by the people from all classes.

Millets are a group of highly variable small-seeded grasses, widely grown around the world as cereal crops or grains. Foxtail millet (botanic name Setaria italica, synonym PanicumitalicumL.) (Thinai in Malayalam) is one type of millet grass grown for human food. It is high in calories, giving strength and energy and considered as diabetic food. Unlike rice, foxtail millet releases glucose steadily without affecting the metabolism of the body. The incidence of diabetes mellitus is rare among the population that consumes foxtail millet containing diet [1]. Its antioxidant property removes acidic element away from the body. Like most millets, is also a good source of crude fiber, helps in the digestive process and helps to induce bowl movement, thus producing a laxative effect that is beneficial for a healthy digestive system [2]. Incorporation of Foxtail millet inburfi may contribute to several physiological benefits as it aidslaxation, helps digestion, treats anaemia, increases bone strength and helps lactation. In addition, it helps in weight loss, reduce cholesterol, haveanti-cancer potential, lower the risk of gallstone and control diabetes. Hence keeping in view the above fact, a study was conducted to optimize the procedure for preparation of burfi incorporated with Foxtail millet and to evaluate the physico-chemical and sensory characteristics of the optimized product.

Milk: The buffalo milk was procured from University Diary plant, Mannuthy and used for product development.

Sugar and Foxtail Millet: procured from local market.

Chemicals and glass wares: Analytical grade chemicals and glass wares were procured from approved firms and manufactures.

Method of Preparation

Preparation of Foxtail Millet Powder

The foxtail millet was procured from local market. It was screened for removing large impurities like stones, twig pieces etc. The foxtail millet was roasted in a Teflon coated pan on a low flame. Cooled it completely (Otherwise it will lump up while grinding).Milled the foxtail millet in a food processor. Did it in intervals to avoid the heat of the processor from getting transferred to the foxtail millet. Run it for a few seconds, giving it a quick stir with a spoon, let it sit for a few more seconds to avoid overheating the processor and then ground again. Transferred the powder into an airtight container and stored it in a dry and cool place.

Preparation of Burfi

The buffalo milk was filtered by passing through muslin cloth and was standardized at 6% fat and 9% SNF. The procedure described by Aneja et al., was followed for preparation of burfi with slight modifications [2].

Method of Preparation of Foxtail Millet Burfi

The milk was concentrated by evaporating in open pan on gentle fire with continuous stirring-cum-scrapping until pasty consistency is obtained. The calculated amount of roasted and ground finger millet as per treatment and sugar at 30% of khoa were added. The mixture was then further heated with continuous stirring using a steel ladle up to desirable solid mass stage attained. The product was then transferred into a greasy tray and was allowed to cool. The final product was cut into rectangular pieces of desirable sizes.

Fig. 1 Flow diagram for the preparation of foxtail millet burfi

Optimization Trials

Optimization of Level of Foxtail Millet Powder

Preliminary trials were conducted and three different levels of Foxtail millet flour i.e., 5%, 10%, 15% were taken for optimisation trials. Optimisation was done based on sensory and textural evaluation..

Evaluation of The Optimized Product

After optimisation, the final product was prepared using buffalo milk khoa with 10% Foxtail millet flour and 30% sugar. The final product was analysed for chemical composition, texture profile and sensory evaluation. Three replications were undertaken for each attribute.

Chemical Composition

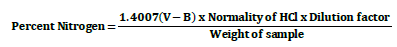

Fat content was determined by Rose-Gottlieb method using Mojonnier extraction. Moisture content of the product was estimated by method recommended by IS:SP:18, 1981. The ash content of the product was determined by using muffle furnace. The total nitrogen content of the burfi was determined by Micro Kjeldahl method [4]. Nitrogen content in the sample was calculated using the expression given below and a factor of 6.38 was used to convert it to percent protein. A blank was also run simultaneously without sample.

where, V=Volume of HCl used for sample titration

B= Volume of HCl used for blank titration

The total carbohydrate content of the product was determined by subtracting the sum of other components from total solids. Titratable acidity of the product was estimated by method recommended by AOAC [5].

Texture profile analysis (TPA): TPA on foxtail millet burfi samples was performed on the Texture Analyser (TA. XT plus), Exponent Lite (Stable Micro Systems, UK). TPA was done to characterize the hardness, factorability, adhesiveness, springiness, cohesiveness, gumminess, chewiness and resilience of the product. The sample of foxtail millet burfi was cut into 2 cm3 size pieces and temperature of the sample was maintained at 25◦C during texture analysis. The samples were subjected to mono-axial compression of 10mm height. The force distance curve was obtained for a two bite compression cycle with the test speed of 5mm/second and trigger force of 5g.

Sensory evaluation: The standardized foxtail millet burfi was evaluated organo-leptically for quality attribute like flavour, body and texture, colour and appearance and overall acceptability by a selected panel of judges comprising five members. A hedonic score card is used for evaluation. Hedonic rating is used to measure the consumer acceptability of the product was rated based on a scale of points ranging from ‘’like extremely’’ to ‘’dislike extremely’’.

The growing public awareness toward nutritional and health benefits foxtail millet is a good choice for preparation of various food items. It is rich in poly-phenols and dietary fibre. In the present investigation effort was made to develop foxtail millet incorporated burfi. During the study the level of addition of foxtail millet flour was optimized. The sensory characteristics and physico-chemical properties were studied. The data obtained were statistically analysed and are presented in this section.

Effect of different foxtail millet flour levels on sensory score of burfi

In order to optimize the foxtail millet flour content, the burfi was prepared that containing 5% foxtail millet flour(T1), 10% foxtail millet flour(T2), and 15% foxtail millet flour(T3) and the control (T0). The effect of different foxtail millet flour levels during the development of burfi incorporated foxtail millet presented in the table 1.

Table 1. Sensory evaluation of foxtail millet burfi (Average values of 4 replications)

| Sl. no | Attributes | Scores assigned | |||

|---|---|---|---|---|---|

| CONTROL T0 | 5% FM POWDER T1 | 10% FM POWDER T2 | 15% FM POWDER T3 | ||

| 1 | Flavour | 8.4 | 7.9 | 8.1 | 7.9 |

| 2 | Body &Texture | 7.8 | 8.2 | 8.6 | 7.9 |

| 3 | Colour & Appearance | 8 | 7.9 | 8.3 | 7.8 |

| 4 | Sweetness | 8.2 | 8.4 | 8.4 | 8.4 |

| 5 | Overall Acceptability | 8 | 7.9 | 8.3 | 7.75 |

Foxtail millet burfi with 10% added foxtail millet got maximum overall acceptability score of 8.3 which is higher than that of the control. Hence, the addition of 10% of foxtail millet powder in burfi (T2) was selected.

Evaluation of The Optimized Product

The results of the proximate analysis are presented in Table 2. The composition of the control and the developed product were analysed in triplicates and average value is calculated.

Table 2. Proximate composition of Foxtail millet burfi

| Parameters | Control Burfi | Foxtail millet burfi (10%) |

|---|---|---|

| Protein | 19.46 | 18.38 |

| Fat | 20 | 15.5 |

| Total Carbohydrates | 44.96 | 51.48 |

| Dietary fibre | 0.11 | 0.89 |

| Ash | 2.47 | 2.85 |

| Total Solids | 87 | 89.1 |

Effect of incorporation of foxtail millet on chemical quality of burfi

Moisture

Moisture represents the presence of water in the sample. Moisture determination is one of the most important analysis performed on a food product. Moisture content greatly influence the physical properties and product quality of nearly all substances and materials at all stages of processing and final product existence. The high moisture content may affect the storage quality of a product and encourage microbial growth [6].

In the present study the average moisture content in control burfi was 13.10% and foxtail millet incorporated burfi was 11.30%. The total solids content in control burfi is 87% and foxtail millet incorporated burfi is 89.10%. This is a clear indicator of increased shelf-life.

Protein

Protein is an essential nutrient for anyone wanting to keep lean and build muscles or just tone up. It keeps our body healthy. In the present study, the percent of protein in foxtail millet incorporated burfi is 18.38% and that of control was 19.46%. The lower value may be because of the addition of millet as the protein content in foxtail millet is much lesser. This finding is in close agreement with Wankhed in mango burfi and Kamble et.al., in pineapple burfi [7] [8].

Fat

Foods we eat contain nutrients that provide energy and other substances the body needs. The body uses fat as a fuel source, and fat is the major storage form of energy in the body. Fat is also having many other important functions in the body, and a moderate amount is needed in the diet for good health. The fat content of the control burfi was 20% and foxtail millet incorporated burfi was 15.5%. Again, the lower value corresponds to the addition of foxtail millet which is lower in fat. This investigation are in agreement with Wankhede (2005) in mango burfi and Kamble et.al., in pineapple burfi . This indicates that the total calorie of the developed product is much lower than the traditional burfi [7] [8].

Fibre

Dietary fibre is important for our digestive health and regular bowel movements. Fibre also helps you feel fuller for longer, can improve cholesterol and blood sugar levels and can assist in preventing some diseases such as diabetes, heart disease and bowel cancer.

Milk is deficient in dietary fibre, so is burfi. The fibre content in the control burfi was 0.11% and foxtail millet incorporated burfi was 0.89%. The addition of millet improves the fibre content in the developed product which helps in improving digestive health.

Ash

Ash is the residue remaining after the organic matter of food has been destroyed by incineration and is the most convenient assessment of total mineral in the material. During ashing the water and volatiles are vaporized and organic substances were burnt off in presence of oxygen. Most minerals are converted to oxides, phosphates, chlorides etc.

The amount of ash in foxtail millet incorporated burfi was found as 2.85% which is slightly higher than control burfi. This indicates a higher mineral content in developed product attributed from added fox tail. The figure for ash content in khoa have been reported to be as high as 4% [9].

Acidity

The acidity of control burfi is 0.405% and foxtail millet incorporated burfi was 0.324%.

Effect of Variables on Textural Properties of Foxtail Millet Burfi

Effect on hardness

Hardness refers that the force necessary to produce a given deformation and is most commonly evaluated when determining the texture of burfi. The average hardness value for foxtail millet burfi was 59007.122 g and that for control was 34403.985g. The addition of foxtail millet burfi increased the hardness of burfi. This may be due to the lower moisture content of foxtail millet powder. The result here is in agreement with walnut powder burfi [9]. Similar findings were reported by Pandey & Poonia in ber powder burfi [10]. But the judges seemed to like the harder version of burfi as the burfi incorporated with 10% foxtail received highest score for body and texture.

Now a day’s people assume a high degree of assurance in wholesomeness and safety of natural foods and natural flavour than artificial flavours based on chemicals. The present study was carried out with an intention to prepare healthy nutritious burfi variety. The scores of burfi for all the attributes except flavour obtained for foxtail millet added at 10% was much higher than other treatments. From the results of the present study, it can be concluded that burfi developed by incorporating foxtail millet powder can be very well utilized for preparation of nutritious, delicious burfi by blending 10% roasted foxtail millet powder by weight of khoa with 30% sugar.