E- ISSN: 2320 - 3528

P- ISSN: 2347 - 2286

E- ISSN: 2320 - 3528

P- ISSN: 2347 - 2286

Zvidzai CJ1*, Munosiyei P1, Muronzi RF1, and Usai T2

1Department of Biology, Bindura University of Science and Education, Bindura, Zimbabwe

2Department of Food Technology and Design Education, Midlands State University, Gweru, Zimbabwe

Received: 23-Aug-2022, Manuscript No. JMB-22-72733; Editor assigned: 25-Aug-2022, PreQC No. JMB-22-72733 (PQ); Reviewed: 08-Sep-2022, QC No. JMB-22-72733; Revised: 03-Jan-2023, Manuscript No. JMB-22-72733 (R); Published: 11-Jan-2023, DOI: 10.4172/2320-3528.12.1.001

Citation: Zvidzai CJ, et al. Biochemical and Microbial Developments of Eleusine Coaracana (Rapoko) Malt based Maheu, a Zimbabwean Non-Alcoholic Beverage. RRJ Microbiol Biotechnol.2023;12:001.

Copyright: © 2023 Zvidzai CJ, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Research & Reviews: Journal of Microbiology and Biotechnology

A study on the microbial and biochemical changes that occurred during the traditional process of rapoko (E. coaracana) malt based maheu was carried out using controlled conditions of initial pH range of 6.0-8.0 and incubation temperature range of 25-40°C over a fermentation period of 48 hr. Under different initial pH and temperature values, the fermentation set-ups showed optimum conditions of initial pH 6.0 and 40°C. The highest acidity value change was from a value of 0.3 to 0.55. The acidity change tallied with the recorded highest increase of microbial counts of LAB at the optimum conditions. However, yeasts and molds showed no much significant differences in log cfu/ml values under all the fermentation conditions. Hence, the differences in acidity change were then attributed to LAB microbes metabolic activities. Sensory evaluation noted a significant difference on the quality of rapoko based maheu when compared to several flavoured commercial maheu products with X-squared=42, df=36, p-value=0.227) and the statistical analysis showed a significant difference with p ≤ 0.05.

Microbial; Biochemical; E. Coaracana; Maheu; Non-alcoholic

Fermentation of food is one of the oldest food processing and improved shelf-life methods which date back to Neolithic period around 10 000 years BC. Traditionally, food fermentation was carried by commensal microbes existing in the raw material or present adventitiously entering through contamination from utensils, environment and the manufacturer. Fermentation in addition provides flavors, and/or signficantly improves the nutritional properties of the raw material and end product therefrom [1].

Finger millet (rapoko) is one of the marginalized grains produced and consumed in India and Africa. E. coaracan grains are known to be nutritionally superior when compared to other major cereals like wheat, rice and maize; as a rich source of calcium, iron and zinc in addition to dietary fiber. Utilization of rapoko cereal is limited due to its marginalization. maheu is a sour non-alcoholic beverage made from various cereals by spontaneous lactic acid fermentation. It is an adult-type food, which is commonly used to wean children and is introduced to infants. Generally, in Zimbabwe maheu is commonly prepared from maize porridge or sorghum flour. The uses of uncontrolled conditions especially temperature may result in the proliferation of undesirable end products which was adversely affect the taste and texture of maheu.

Rapoko maheu production is still an artisanal process at rural household level and characterized by absence of instrumental and analytical control processes in producing this non-alcoholic beverage. The knowledge on rapoko maheu production in Zimbabwe has not been scientifically documented and is in danger of being lost as technologies evolve and families move away from traditional food preservation practices. This research was focused on the biochemical and microbial changes that occur during rapoko fermentation. The microorganisms responsible for the fermentation are poorly studied and are thought to include wild yeasts and bacteria from fermentation pots passed from previous fermentations. This study will help with scientific documentation of rapoko based maheu. This project gives insights on potential identification of starter cultures for the production of a consistent quality product and for understanding their role in the fermentation process and final product quality [2-18].

Procedure for traditional rapoko maheu preparation and inoculum development

Ready and traditionally processed E. coaracana (rapoko) flour was obtained from a local agricultural market, Mpata in Chinhoi, Zimbabwe. The word for maheu brewing processes was prepared according to traditional techniques, then left for fermentation in conditioned traditional pots over 48 hr. Rapoko malt flour weighing 540 g was mixed with 1.2 liters of water then boiled using a hot plate until a thick porridge was obtained then allowed to cool to room temperature. After cooling, the porridge was aliquoted into equal volumes and poured into 250 ml volume sized clay pots. The newly used pots were conditioned overnight by allowing them to stay for 60 hr with previously prepared maheu in traditional pots prior to their usage. The experimental pots were then covered with aluminium foil and left for fermentation at controlled pH or temperature. Spontaneous fermentation was allowed to occur in the pot from the conditioning process (Figure 1).

Effect of temperature on rapoko maheu production

Effect of temperature was carried out by placing the pots under incubator conditions set at 25, 30 and 40°C, then profiles on acidity and pH using a pH meter of the maheu was determined. Aliquot samples of 5 ml were withdrawn at intervals from the pots and kept in fridge at 4°C. All experimental set ups were done in quadruplets [19].

Effect of pH on rapoko maheu fermentation

Effect of initial pH at 6.0, 7.0 and 8.0, using phosphate buffers on acidity and pH changes during fermentation of maheu was also evaluated. Samples for analysis were treated similarly as mentioned above. All experimental set ups were done in quadruplets.

Biochemical analysis

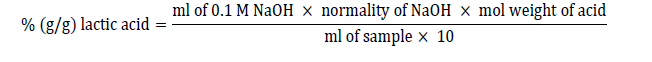

Titratable acidity: Titratable acidity was being measured immediately after sample collection. The supernatant (5.0 ml) collected during fermentation was be transferred into a conical flask and diluted twice with distilled water. The solution was titrated against 0.1 M NaOH using phenolphthalein as the indicator. The amount of acid produced was calculated as per cent lactic acid according to the formula:

All assays were done in triplicates [20].

Alcohol content analysis

The alcohol content of maheu was determined during fermentation using a vinometer which has a scale of 0-25% (v/v).

Microbiological analysis

A volume of 1.0 ml of maheu samples from each pot was dissolved in 9.0 ml of sterile saline salt solution. Then subsequently used to perform serial dilutions. Each serial dilution amounting to a volume of 0.1 ml was be spread on petri dishes containing Plate count agar (DIFCO), man, rogosa and sharpe agar (oxoid), yeast peptone agar (sigma aldrich) and sabouraud dextrose agar (sigma aldrich) then incubated at 30°C for about 2 days. Plate count agar containing Petri dishes were incubated at 37°C for 24 hours to test for total aerobic mesophilic bacteria. MRS agar plates were incubated at 37°C for 48 hours to test for Lactic Acid Bacteria (LAB). Yeast count was performed using yeast peptone agar. Sabouraud dextrose agar was used as a medium for enumeration of total yeasts and moulds [21].

Organoleptic tests

A panel of 8 trained and 10 untrained tasters were chosen to perform a sensory evaluation of the fermentation optimized conditions product. Sensory properties of product were evaluated on a 0-9 Heldonic scale in terms of the following characteristics: Aroma, taste, mouth feel, thickness, texture, colour and general acceptability [22].

Data and statistical analysis

Analysis of Variance (ANOVA) was be used to determine whether or not there were significant differences between the microbial and biochemical changes that existed between the maheu fermented using the clay pot and that commonly fermented using sorghum malt flour. A one factor Completely Randomized Design (CRD) was utilized in optimization for evaluating the optimum conditions [23].

Effect of temperature on rapoko maheu production

Results from Figure 2 shows that there was a notable change in maheu pH from 6.0 to 3.6 (2.4 units) at 40°C as compared to 25 and 30°C. The noted highest pH change matched the change in acidity with about 0.24 units, confirming the biochemical changes in organic acids. However at 25°C, the maheu’s pH profile change was quite low and this matched the lowest acidity changes that had a value of 0.18 units. The optimum temperature for fermentation of rapoko (E. coaracana) malt based is 40°C [24].

The change in temperature on the rate of rapoko malt based maheu’s acidity profile over 48 hr of fermentation was analyzed with XLSTART. After performing one way ANOVA the results (F=136.22, p=0.00) it was shown that there is a significant difference in different temperatures, (p<0.05) on the Titratable Acidity (TA) during fermentation, with the optimum temperature at 40°C.

Effect of initial pH on rapoko malt maheu acidity and pH profiles

Effect of initial pH using phosphate buffer on the rate of rapoko malt based maheu’s acidity and pH profile over 48 hours of fermentation is shown in Figure 3. It was interesting to note that, at an initial of pH 6.0 the pH profile showed a decrease of 2.76 units, with an acidity decrease of 0.20 units over a period of 48 hours. The lowest pH change was recorded when the initial pH of fermentation of maheu was at an initial pH of 8.0, giving a pH change of 2.4 units and the acidity had a slight change of 0.13 units. The results showed that the initial pH of 6.0 is the optimum for the fermentation of rapoko malt based. These pH and temperature optimum conditions were observed elsewhere [25-32].

Therefore, the determined optimum pH and temperature values for rapoko (E. coaracana) malt based maheu fermentation are 6.0 and 40°C.

Figure 3: Effect of initial pH using phosphate buffer on the rate of rapoko (E. coaracana) malt based maheu’s acidity and pH profile over 48 hr of fermentation. Acidity profiles at initial pH of (◊) pH 6.0, (□) pH 7.0 and (○) pH 8.0 and pH profiles at initial pH of (♦) pH 6.0, (■) pH 7.0 and (●) pH 8.0.

The change in initial pH buffers on the rate of rapoko (E. coaracana) malt based maheu’s acidity profile over 48 hr of fermentation was as well analyzed with XLSTART (F=112.55, p=0.00). One way ANOVA results showed that there is a significant difference in different temperatures, (p < 0.05) of the Titratable Acidity (TA) during fermentation [33].

Microbiological analyses results

Lactic acid bacteria changes in rapoko malt maheu: The results for Lactic acid bacteria population changes in rapoko malt based at temperatures 25°C, 30°C and 40°C are shown in Figure 4 below. At 25°C, Lactic Acid Bacteria (LAB) population increased from 6,0 to 8,9 (log cfu/ml) over 48 hours and at 40°C microbial population increased with a highest change of 3.6 log cfu/ml units. However, at 40°C the recorded LAB population increased with the least cfu/ml units over the same period. It was observed that the highest notable change in LAB population was at 30°C, hence this could be attributed to the generally assumed optimum temperature for culturing LAB microbes [34,35].

The optimum conditions noted above were observed to produce the most favourable conditions for LAB growth as shown in Figure 4 below that produced the highest microbe population at 30°C.

The statistical analysis showed a significant difference, (p ≤ 0.05) in Lactic acid bacteria at different phosphate buffers 6, 7 and 8 over 48 hours. The statistical difference was determined by one way ANOVA, producing a total bacteria count, (F=3, 88; p=0,96).

Yeasts and moulds changes of rapoko malt maheu

Yeasts and moulds population changes in rapoko malt based maheu at 25°C increased by 3, 4 units (log cfu/ml) over 48 hr and at 40°C it was by 3.9 units. However, the optimum temperature of 30°C observed in the above analysis seemed to be the optimum for the yeasts and molds giving rise to a population change of 4.4 (log cfu/ml) units over the same 48 hr period as shown in Figure 5 below.

The statistical analysis showed a significant difference, (p ≤ 0.05) in yeasts and molds at different phosphate buffers 6, 7 and 8 over 48 hours. The statistical difference was determined by one way ANOVA, total yeasts and molds count, (F=3,88; p=0,98). Equally for the Total aerobic mesophilic bacteria population changes in rapoko maheu with the same phosphate buffers showed a significant difference, (p ≤ 0.05). The statistical difference was determined by one-way ANOVA giving a total aerobic mesophilic bacteria count of (F=5, 14; p=0,82).

Overally, the initial desired pH, optimum microbial growth of LAB and other related microbes and fermentation conditions were noted to be initial pH 6.0 and temperature of 40°C.

Organoleptic and sensory evaluation

Sensory evaluation tests were performed and results are illustrated in Figure 6 in comparison to a natural commercial sorghum maheu produced by a local Zimbabwean company. It was quite interesting to note that on a 0-9 hedonics scale (N=16, 89%), rapoko maheu was more preferred under majority of the attributes tested especially on colour, sourness, thickness, after taste and smoothness.

It was quite interesting to note that, in terms of flavour, instead, the commercial traditionally prepared sorghum maheu was preferred in comparison to rapoko maheu. The majority of panelists (N=14, 78%) indicated that rapoko maheu had no after taste attribute noted with the sorghum maheu. However there was a major notable difference in sweetness and brewery end product associated with their wort taste qualities. Rapoko word has much high sugar concentration as reported elsewhere during preparation of mangisi and masvusvu.

Pearson's Chi square test was carried out on the sensory evaluation results (X-squared=42, df=36, p-value=0.227) and the statistical analysis showed produced a Figure of p ≤ 0.05). Hence we concluded that there is a significant difference on the quality of rapoko based maheu compared to the currently and commercially produced maheu using sorghum malt. However, the commercial product is currently being flavoured with different fruits like banana, strawberry and mango but still those variants do not compare to the rapoko maheu in a number of sensory attributes.

Effect of temperature and initial pH on rapoko maheu production

The effect of temperature on the rate of rapoko malt based maheu’s fermentation with reference to decrease in pH and an increase in acidity had the optimum temperature condition to be at 40°C. Low temperatures normally reduce membrane fluidity and hence restrict transport of essential nutrients and other elements that require for efficient microbial metabolic processes. By so doing there is a slowdown in enzymatic cellular requirements. Other studies have shown that use of growth temperature of 40°C was promotes development of mesophilic bacteria of lactic acid producing bacteria that include the likes of Lactococcus lactis subsp. lactis, Lactococcus lactis subsp. cremoris and Leuconostoc mesenteroides subsp. cremoris.

The optimum initial pH using phosphate buffers was at pH 6.0, for the production of rapoko (E. coaracana) malt based maheu. It is interesting to note that, pH affects ionization thereby influencing the folding of enzymes. Enzymes for Lactobacillus species are normally active at low pH values of around 5.5-6.5 and lactic acid bacteria normally grow at low pH. The lactic acid produced avails environmental conditions that are not conducive for the survival of spoilage bacteria since lactic acid is a natural preservative that inhibits putrefying bacteria and is responsible for the improved microbiological stability and safety of the food. The ability to convert carbohydrates to lactic acid, acetic acid, alcohol and carbon dioxide with only minor changes in the other food components has made lactic acid bacteria extremely important in the preservation of food. There is little calorific change in the conversion of carbohydrates to lactic acid and very little loss of total nutritive value.

Effect of initial pH and temperature on microbial profile on rapoko maheu production

Although the acidity leads to the souring of the final product which is characteristic of fermented grains and vegetables, however there is a possibility the presence of hydrogen peroxide that aids antimicrobial and other potent antimicrobial compounds such as superoxide and hydroxyl radicals as recorded elsewhere emanating from Lactobacillus, Leuconostoc and Pediococcus species. Further production of diacetyls from Leuconostoc, Lactococcus, Pediococcus and Lactobacillus is effective against putrefying bacteria including enteropathogenic as well as imparting flavour and taste. In addition, fermented foods have LAB microbes as major players in affecting the rheological and flavoring properties.

Other studies noted optimal pH for the LAB growth at pH 7.0 and low growth was recorded at 4.5. Similar results were found by Mataragas, et al. however the low biomass development was noted to be suppressed by bacteriocin production from lab microbes.

There was an exponential increase in total aerobic mesophilic bacteria population in all the phosphate buffered maheu. Total aerobic mesophilic bacteria is known to comprise of starch hydrolyzing bacteria and Enterobacter population throughout the fermentation process. Yeasts and moulds population also increased in all the phosphate buffer treatments. Optimum pH for mesophilic bacteria was pH 6.0.

Yeasts and moulds population showed optimum production at 40°C. Yeast count increased probably due to the availability of essential nutrients for lactic acid bacteria growth and a favourable environment for yeast activity. The nutrients such as proteins and vitamins were made more easily available to lactic acid bacteria through reduction in size during pounding and cooking and also by the autolysis of yeast or other biological factors as was reported by Tou and coworkers.

Lab bacteria provides the acidic environment which selects the substrate for the growth of yeast and the yeast in turn provides the vitamins and other growth factors to the bacteria.

The optimum conditions here obtained were in agreement with the reports of Antony, et al., using finger millet malt but this was in sharp contrast to other fermentations like kenkey, ogi and mawe prepared from sorghum and maize. The lower population of yeasts recorded in rapoko based maheu could be due to the unfavourable pH during initial hours.

There is need to isolate, identify and characterize the microorganisms involved in the production of rapoko based maheu in an attempt to improve this rapoko beverage by coming up with improved and standard quality starter cultures. Currently, the manufacture of rapoko based maheu is declining because of poor hygienic quality, short-life and variations in organoleptic and hygienic quality.

Sensory and alcohol evaluation

According to the hedonic scale results, rapoko maheu had a darker colour compared to that of the commercial sorghum maheu. Some tasters preferred the red brown colour of rapoko based maheu whilst others preferred the dark brown colour of commercial sorghum maheu. The color of the rapoko based maheu is very important from consumer points of view because it is the color which appeals first to a person to purchase or consume any food. Rapoko maheu had a sourer taste compared that of the commercial sorghum maheu. Commercial sorghum maheu and rapoko maheu were both rated to have the same sweetness. Rapoko maheu were thicker compared that of the commercial sorghum maheu. Gelatinization contributes to the thickness of maheu by the swelling of starch granules. This means that less malt will cause less conversion of starch molecules to glucose and more water is going to be incorporated. It also depends on the processing stages which may alter product viscosity.

Rapoko maheu were smoother compared to that of the commercial sorghum maheu. Commercial sorghum maheu had a more flavour associated to the smell of maheu compared to rapoko but however had a distinct and refreshing sour taste.

Rapoko maheu had a slight after taste compared to that of the commercial sorghum maheu due to the high tannin levels in rapoko malt. The rapoko maheu had very low levels of alcohol levels (0.15 v/v%) as recorded elsewhere. However if the agricultural cultivations are optimized for rapoko production then we expect a consistent rapoko malt. Both rapoko maheu and commercial sorghum maheu had no defects that include foreign particles, lumps, moulds and pungent smells. Product defects will affect the quality thereby affecting market share.

Microbial and biochemical changes that occurred during the production of rapoko malt based maheu had a progressive fall in pH and a rise in titratable acidity. The decrease in pH and increase in total acids is due to the production of organic acids and primarily that of lactic acid generated by lactic acid bacteria. It was assumed that lactic acid bacteria secretion lowers the pH and allows the yeast population to become competitive in the immediate environment. The co metabolism between yeast and lactic acid bacteria could be attributed to their increase in cfu/ml values allowing their co-existence whereby the bacteria provided the acid environment which and the yeast provided the vitamins and other growth factors to the bacteria. The low colony count of yeasts indicates that the fermentation was of low alcoholic production. The results provided a sound basis of shifting to an instrumental and analytical control on the production process of rapoko malt based maheu from artisanal production but coming up with starter culture for commercialization scale. However, there is need to finally perform shelf-life properties evaluation on the maheu final product quality despite the presence of lactic acid probably additives of other preservatives can improve the shelf-life.

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]

[Crossref] [Google Scholar] [PubMed]