ISSN ONLINE(2319-8753)PRINT(2347-6710)

ISSN ONLINE(2319-8753)PRINT(2347-6710)

Sunil Kumar R1, Nagaprasad K.S2

|

| Related article at Pubmed, Scholar Google |

Visit for more related articles at International Journal of Innovative Research in Science, Engineering and Technology

Diesel engines are the main power source for the automobiles but emission norms are strict for any engine. Among the main pollutants PM, NOx, CO, HC, SOx, aldehydes most harmful pollutants of diesel engine are NOx and PM. Exhaust gas recirculation (EGR) is effective for the reduction of NOx emission from engines but also reduces efficiency. This happens due to accumulation of burnt gases in combustion chamber. Diesel Particulate Filters (DPF) are designed to reduce the mass emissions of diesel particulate matter and have proven to be effective in this aspect. The aim of this work is to analyze the effect of EGR on the engine performance and exhaust emission characteristics. The work carried out on the four stroke four cylinder Diesel engine. Experimentation involves the addition of oxygenated fuel Di-Ethyl Ether with the Diesel fuel. The results showed the increase in brake thermal efficiency and decrease in specific fuel consumption with increase in EGR valve opening due to the supply of extra oxygen molecule by the additive. Further, a significant reduction in the emissions of PM, NOx, HC, CO was observed with the application of DPF into the exhaust of engine.

Keywords |

| Diesel Engine, Exhaust Gas Recirculation, Diesel Particulate Filters, Di-Ethyl Ether. |

I. INTRODUCTION |

| Energy consumption is increasing globally in various forms for different purposes. To determine the potential of di-ethyl ether (DEE) for use as a transportation fuel, it is necessary to understand its engine and emissions performance characteristics, as well as what it might cost. Although DEE has long been known as cold-start aid for engines, knowledge about using DEE for other applications, such as a significant component of a blend, or as a complete replacement for diesel fuel is limited [8]. |

| Exhaust Gas Recirculation (EGR) is a pre-treatment technique, which is being used widely to reduce and control the oxides of nitrogen (NOx) emission from diesel engines. EGR controls the NOx because it lowers oxygen concentration and flame temperature of the working fluid in the combustion chamber. However, the use of EGR leads to a trade-off in terms of soot emissions. Higher soot generated by EGR leads to long-term usage problems inside the engines such as higher carbon deposits, lubricating oil degradation and enhanced engine wear [5]. |

| For many years, diesel engine manufacturers have been working extensively to develop Aftertreatment technologies that are capable of significantly reducing the emission levels of each of the primary pollutants which are considered to be a risk to the environment and public wellbeing. The majority of these Aftertreatment technologies have been designed with the most consideration being given to compounds such as particulate matter (PM), oxides of nitrogen (NOx), carbon monoxide (CO), and hydrocarbons (HC). One primary aftertreatment technology commonly used to reduce the PM emission levels of diesel exhaust is the diesel particulate filter (DPF). [9]. |

II. LITERATURE REVIEW |

| Hartmut Luders et.al. [2] describes new approach to ultra emissions Diesel vehicles that comply with the proposed emission standards. Advanced exhaust gas aftertreatment technology, including Diesel particulate filters and NOx catalysts were investigated with regard to suitability for large-scale vehicle application. Diesel combustion system development, in the form of state-of-art engine technologies and Diesel exhaust aftertreatment can independently and substantially reduce both particulate emissions and NOx emissions to very low levels. |

| Harilal S. Sorathia et. al. [6] reviewed the effect of exhaust gas recirculation (EGR) to reduce the NOx emission from tailpipe of homogeneous charged C.I.engines. Cooled exhaust gas recirculation is a common way to control the NOx generation in engine cylinder. It was found that adding EGR to the fresh air charge to homogeneous charged engines will beneficial to reduce the NOx emission substantially. EGR displaces oxygen in the intake air and dilute the intake charge by exhaust gas recirculated to the combustion chamber. Recirculated exhaust gas lower the oxygen concentration in combustion chamber and increase the specific heat of the intake air mixture, which results in lower flame temperatures. |

| M.V.Mallikarjun et. al. [7] attempts to identify the potential of blending DEE with diesel transportation fuel. Ethanol can be easily converted through a dehydration process to produce Diethyl Ether (DEE), which is an excellent CI fuel with higher energy density than ethanol. DEE has long been known as a cold start aid for engines, but little is known about using DEE as a significant component in a blend or as a complete replacement for diesel fuel. DEE is estimated to have a high cetane number and is a liquid at room temperature. It looks attractive as a fuel for CI engines due to its low auto ignition temperature, high volatility and wide flammability ranges. DEE initiates the combustion of the airfuel mixture and hence better and complete combustion takes place. |

| Z. Gerald Liu et. al. [9] suggested that Diesel particulate filters are designed to reduce the mass emissions of diesel particulate matter and have been proven to be effective in this respect. The species analyzed included both criteria and unregulated compounds such as particulate matter (PM), carbon monoxide (CO), hydrocarbons (HC), inorganic ions, trace metallic compounds, elemental and organic carbon and other organic compounds. The DPF aftertreatment system reduced the total particulate matter mass emissions by approximately 98%. Correspondingly, similar reductions were observed for each of the major PM constituents. |

III. EXPERIMENTAL RESULTS |

| The main fuel used for the running of the engine is Diesel. Di-ethyl ether is used as blends with diesel at various proportions. DEE is a strong oxidizing agent and a weak acid in water solution. The formula is similar to that of water, with an extra atom of oxygen attached, C4H10O. Table 1 shows the properties of Diesel and Di-ethyl ether blends with diesel in the experiments. |

|

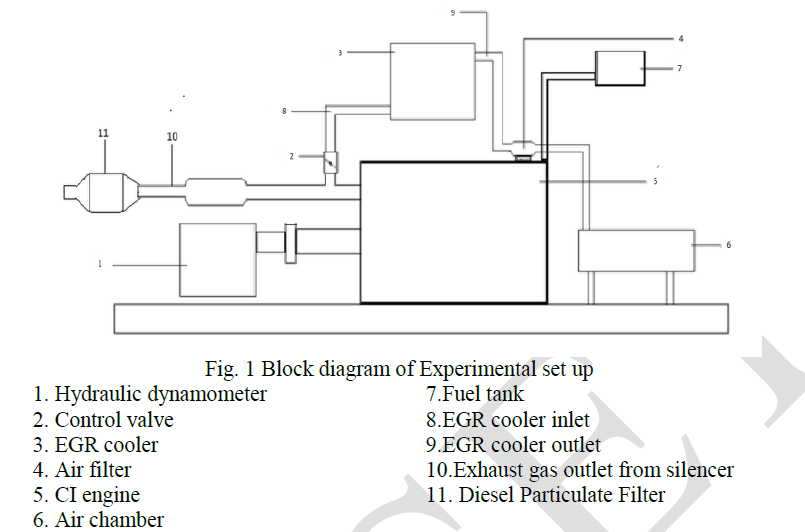

| Experiments are conducted a four stroke, four-cylinder, water cooled CI engine. The fig 1 shows the block diagram of Diesel engine test rig with EGR, DPF arrangement. |

|

| The Diesel Particulate Filter (DPF) is placed in the exhaust line of the CI engine. The exhaust gas from the silencer passes through the diesel particulate filter. Thus the exhaust gases containing the particulate matter gets filtered and clean gases passes to the atmosphere. DPF is loaded with precious metal and thus enhancing regeneration. |

IV. RESULTS AND DISCUSSIONS |

| The investigation of diesel engine performance is done by blending diesel with diethyl ether with and without EGR. The analysis is done in the sequence of comparison of performance obtained at different concentrations of diesel fuel with di-ethyl ether at different ratios of 10% and 20% for various EGR valve openings. |

| The variation of brake thermal efficiency and exhaust gas temperature at different load has been presented and discussed. The engine speed is kept at a constant speed of 1200rpm with an EGR valve opening of 1/4, 1/2, 3/4. The results were analyzed as follows. |

| A. Performance characteristics of Neat Diesel with and without EGR. |

| The brake thermal efficiency was measured with brake power for all test turns with and without EGR for 4, 8, 12, 16 kg loads as shown in fig A.1. The brake thermal efficiency has been found to decrease by recirculating exhaust gas. This happens due to burnt gas occupying the engine cylinder which thereby reduces the availability of oxygen for combustion. The maximum brake thermal efficiency has been found to be 13.34% at 4931.04 W for without EGR condition. |

| The Exhaust gas temperature is compared with brake power for all the test turns with and without EGR for 4, 8, 12, 16 kg loads as shown in fig A.2. It is found that exhaust gas temperature reduces with the application of E.G.R which in turn reduces the NOx pollutant in the engine emission. The minimum value of exhaust gas temperature is found to be 148°C for a brake power of 4931.04 with 1/4 valve opening for EGR. |

|

| B. Performance characteristics of Diesel blended with 10% Di-Ethyl Ether with and without EGR at 1200rpm. |

| The brake thermal efficiency was measured with brake power for all test turns with and without EGR for 4, 8, 12 and 16 kg loads. The brake thermal efficiency has found to increase by injecting the diethyl ether. The reason is that the di-ethyl ether which is added as an additive supplies an extra oxygen molecule for burning to the fuel. The maximum brake thermal efficiency for a brake power 4931.04 W is found to be 16.52% at 3/4 EGR valve opening as shown in fig B.1. |

|

| The Exhaust gas temperature (EGT) is compared with brake power for all the test turns with and without EGR for 4, 8, 12 and 16 kg loads. It is found that EGT reduces with the application of E.G.R which in turn reduces the NOx pollutants in the engine emission. The minimum value of exhaust gas temperature was found to be 144°C for a brake power of 4931.04 W with 1/4 EGR valve opening shown in fig B.2. |

|

| C. Performance characteristics of Diesel blended with 20% Di-Ethyl Ether with and without EGR at 1200rpm |

| The brake thermal efficiency was measured with brake power for all test turns with and without EGR for 4, 8, 12 and 16 kg loads. The brake thermal efficiency is found to increase by injecting the diethyl ether. The maximum brake thermal efficiency at 4931.04 W is found to be 16.74% with 3/4 EGR valve opening as shown in fig C.1 |

| The Exhaust gas temperature (EGT) is compared with brake power for all the test turns with and without EGR for 4, 8, 12 and 16 kg loads. It is found that Exhaust gas temperature reduces with the application of E.G.R. The minimum value of EGT for a brake power of 4931.04 W is found to be 140 °C with 1/4 EGR valve opening shown in fig C.2. |

|

|

| D. Comparison of Neat Diesel and Di-Ethyl Ether blends with and without EGR at 16 kg load |

| The Brake thermal efficiency is plotted for different fuel blends at various EGR valve openings at 16 kg load as shown in fig D.1. It is found that the brake thermal efficiency increases by increasing the EGR valve opening except for neat diesel fuel. The maximum brake thermal efficiency is found to be 16.74% for 20% C4H10O blends at 3/4 EGR valve opening. The least brake thermal efficiency is 11.31 % at 3/4 EGR valve opening which is obtained for neat diesel fuel. |

| The Exhaust Gas Temperature for different fuel blends at various EGR valve openings. The exhaust gas temperature has decreased by recirculating the exhaust gases for all the fuel blends at different EGR valve openings. The minimum Exhaust Gas Temperature was found to be 140°C for 20% DEE blend at 1/4 EGR valve opening as in fig D.2. |

|

|

| E. Emission Measurement at 180 Bar Injection Pressure at 16 kg Load for 3/4 EGR Valve Opening. |

| The fig E.1 shows the PM emission with Diesel blends. The result shows that with the usage of DPF, the PM emission has been decreased at larger rate. This happens due to the precious metal present in the DPF which enhances regeneration. The PM emission has been increased with the EGR for neat diesel fuel whereas in the case of 20% Diethyl ether, it has diminished. |

| The lowest PM emission is found with DPF and DOC for neat diesel fuel at without EGR condition. Overall there has been about 95% reduction in PM emission with the usage of DPF. |

| Fig E.2 displays the NOx emissions for neat Diesel and as well as for diesel and 20% Di-ethyl ether blend. The result showed that NOx emission has been decreased with the application of aftertreatment devices. The NOx emission was dropped to a minimum with the usage of DPF for 3/4 EGR valve opening. There is a significant decrease in NOx emission with the usage of aftertreatment devices. |

|

|

V. CONCLUSIONS |

| After the investigation of diesel engine performance by blending diesel with di-ethyl ether (DEE) with and without EGR system, it is shown that no major modifications are required for EGR installation in the existing engine, except for the fuel. Even though the brake thermal efficiency of CI engine decreases with EGR system, the injection of DEE has drastically enhanced the efficiency for more than the normal performance with EGR system. |

| There has been increase in brake thermal efficiency by using DEE as an additive with diesel. The value of Exhaust Gas Temperature has been decreased with the application of exhaust gas recirculation. |

| Particulate matter emission has been decreased at a larger rate by the usage of DPF. There has been a decrease in PM emission by over 95% with the application of DPF. Also, Nitrogen oxides (NOx) emission has considerably reduced with usage of aftertreatment device for with EGR condition. |

| By all these results it can be concluded that the aftertreatment devices are active in reducing the engine emissions and are necessary in attaining the required emission norms. |

References |

|