Page 51

Notes:

conferenceseries

.com

Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

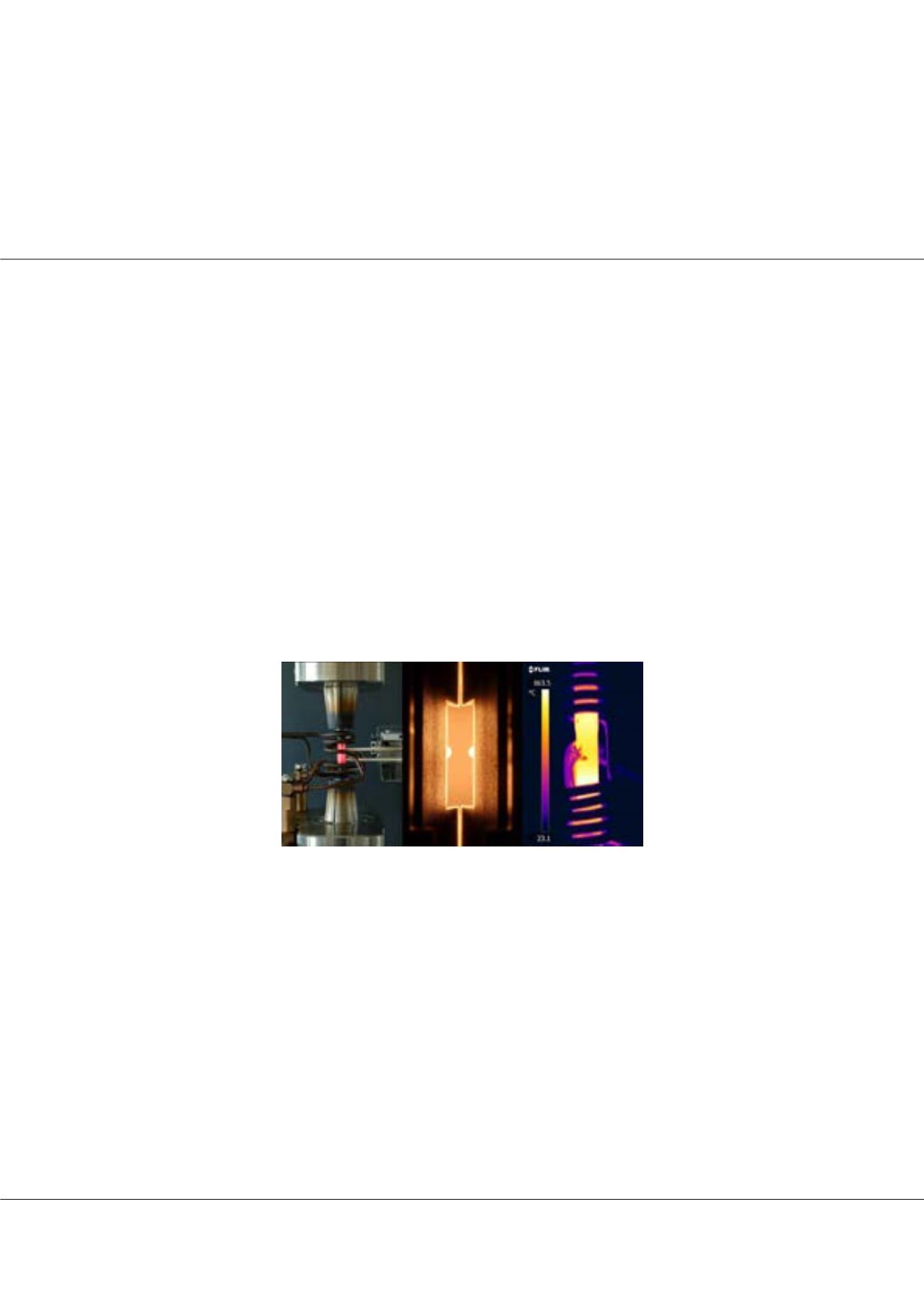

Testing methodologies for thermo-mechanical fatigue evaluation in advanced aerospace materials

Mark Whittaker, Jonathan Jones, Ashley Dyer

and

Jennie Palmer

Swansea University, UK

F

atigue failures are common within structural components used throughout a range of industrial sectors, and are often a critical

design criterion during the specification and development stage of a new product. However, most mechanical testing is performed

under isothermal conditions whichmay not be truly representative of in service conditions.Thermo-mechanical fatigue (TMF) testing

offers the opportunity for the evaluation of a range of advanced material under more appropriate thermal cycles, hence providing

more appropriate lifing approaches to ensure component integrity. TMF tests however, are complicated and difficult to perform, with

much consideration necessary to understand the complex interactions of issues such as the heating/cooling method, the phase angle

between thermal and mechanical strains/stresses, temperature measurement techniques and cycle frequencies. Over the past 15 years,

the Institute of Structural Materials at Swansea University has devoted significant effort in a number of developmental programmes

which have led to internationally recognised expertise in experimental setup and lifing approaches. Consideration in this paper is

given to the experimental difficulties associated with using traditional techniques for temperature and crack length measurements

(thermocouples and direct current potential difference techniques) and the possibility of utilising more innovative approaches such

as thermography is discussed. Research has shown that it is difficult to design a single solution for TMF testing due to the numerous

testing requirements that include peak cycle temperature, heating/cooling rate, and the impact of electromagnetic fields associated

with induction coils. As such, TMF experiments are often by their very nature, bespoke. Future developments such as the generation

of a validated code of practice for crack growth measurements under TMF loading are also discussed.

Biography

Dr Whittaker joined Swansea University in 2003 and has produced over 60 publications including an invited book chapter and 40 papers in leading international

journals on topics including High Temperature Lifing, Thermo-Mechanical Fatigue and Modern Creep Lifing Approaches. He is also a Board Member of the

IOM3 Structure and Properties of Materials Committee. Current research programmes involve sponsorship from EU Clean Skies, Rolls-Royce, EPSRC and

ATI. Dr Whittaker has over 15 years of experience in a wide range of alloys and is leading the development of a code of practice for thermo-mechanical fatigue

crack propagation testing. He is also heavily involved in creep lifing of alloys for the power generation/aerospace sectors, with particular expertise in property

extrapolation using the recently developed 'Wilshire equations'.

m.t.whittaker@swansea.ac.ukMark Whittaker et al., Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-005