Page 53

Notes:

conferenceseries

.com

Volume 5, Issue 5

Res. Rev. J Mat. Sci. 2017

ISSN: 2321-6212

Advanced Materials 2017

September 07-08, 2017

September 07-08, 2017 | Edinburgh, Scotland

Advanced materials & Processing

11

th

International Conference on

Permanent magnets in energy applications for the clean environment

Spomenka Kobe, Marko Soderžnik

and

Kristina Žagar

Jožef Stefan Institute, Slovenia

R

are-Earth Transition Metals permanent magnets are vital components in the rapidly-developing renewable energy sector,

where the motors for electric vehicles and the generators in wind turbines require strong magnets with the ability to operate at

temperatures well over 100°C. To achieve high coercivity, remanence and consequently high-energy product at elevated temperatures

the addition of heavy rare earth (HRE) to the basic Nd-Fe-B composition is needed. On the list of Critical Raw Materials published

by the EC in 2014, HRE is on the very top of it. To drastically reduce the use of HRE we focused on developing a new method, which

should enable us to achieve the properties needed for high-temperature application with the lowest amount of scarce elements.

The significant progress was attained by using electrophoretic deposition as a method for accurately positioning the HRE on the

surface of a sintered Nd-Fe-B magnet before its diffusion into the microstructure. After the additional annealing, this process locally

increased the coercivity of final magnet, thereby substantially reducing the dependence on the HREs, Dy, and Tb1-

3

. By our new

inventive technique further transferred to a pilot production, we could minimize the amount of HRE used, down to 0.2 at %, the

improvement of coercivity was 30 % with minimal loss in remanence. The total saving of the HRE is 16-times less need for the same

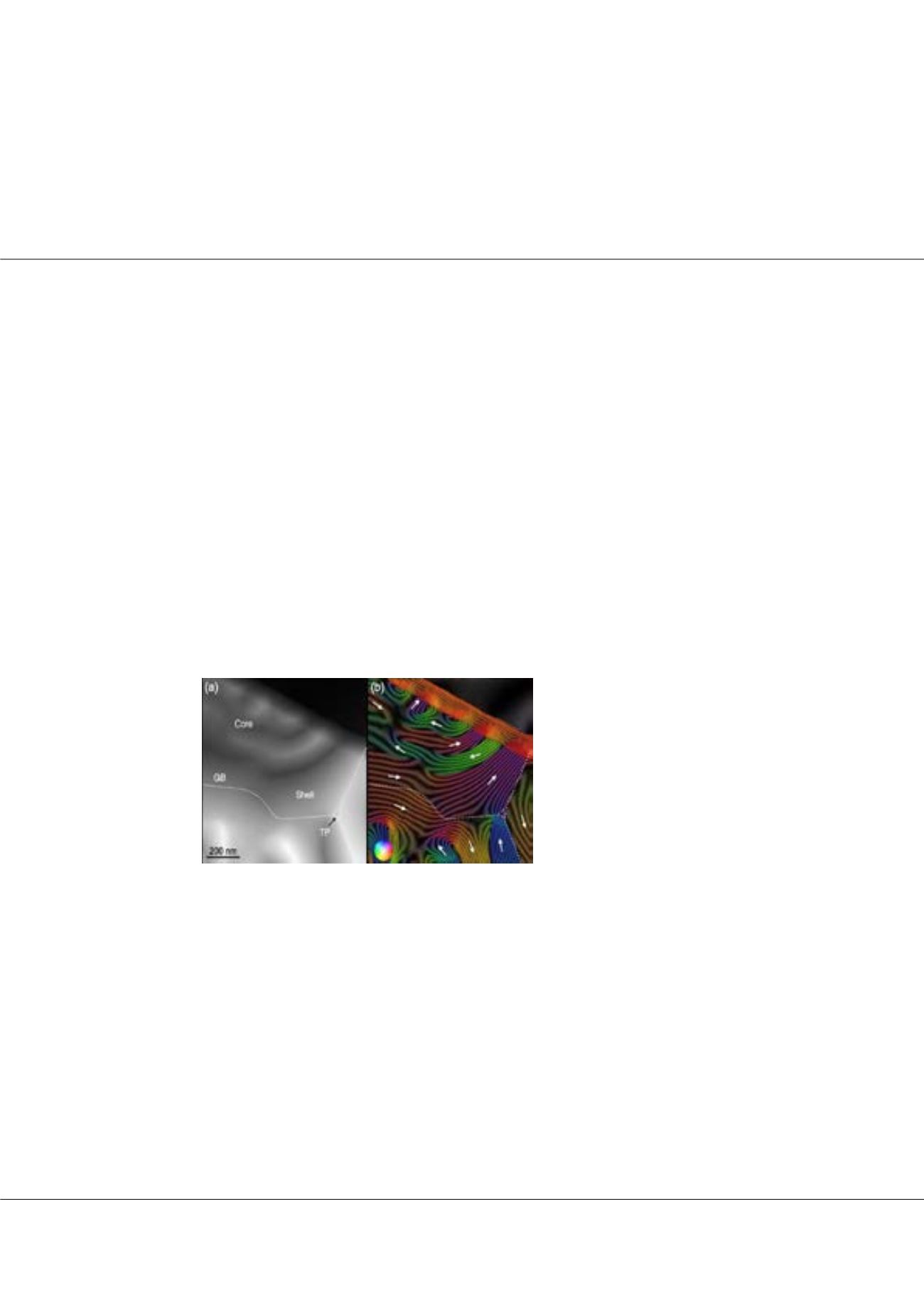

performance, which is a significant contribution to the world economy and clean environment. In studying the mechanism for such

an improvement in coercivity without significantly decreasing the remanence, a detailed microstructure investigation was performed

by using high-resolution transmission microscopy and analysis at the nano level (Fig. 1). Besides the use of these new developed high

energy magnets for electric and hybrid cars and the wind turbine generators the important application is also as the source of the

magnetic field in the development of the new magnetic cooling devices.

Biography

Prof. Spomenka Kobe is Scientific Advisor, Head of the Department for Nanostructured Materials and a Member of the Scientific Council at the Jožef Stefan Institute.

She is a full professor at the International Postgraduate School “Jožef Stefan”. Prof. Kobe is the Leader of the National Research Programme “Nanostructured

Materials”. She is the recipient of two State Awards for Scientific Research and two Innovation Awards from industry for the successful transfer of technology. Her

scientific work is documented in more than 150 refereed publications, 7 chapters in a book and invited talks at international conferences. Her applied research

achievements include 5 patents (2 EP), 3 innovations and 5 successful transfers of technology to the industrial production. Prof. Kobe is also the previous President

of the Academic Society for Science and Engineering (SATENA) and an acting Vice-Chair for the European Commission. She supervised 15 doctoral students.

spomenka.kobe@ijs.siSpomenka Kobe et al., Res. Rev. J Mat. Sci. 2017, 5:5

DOI: 10.4172/2321-6212-C1-005

Fig.1

:

Electron Holography of the core/shell

region. (a) Total phase image with marked

location of the grain boundaries (GB) and the

triple pocket (TP). (b) Reconstructed phase

showing the magnetic flux distribution and

color maps. The contour spacing is π/2.