Page 46

conferenceseries

.com

Volume 6

Research & Reviews: Journal of Material Sciences

ISSN: 2321-6212

Ceramics 2018

May 14-15, 2018

May 14-15, 2018 | Rome, Italy

4

th

International Conference and Expo on

Ceramics and Composite Materials

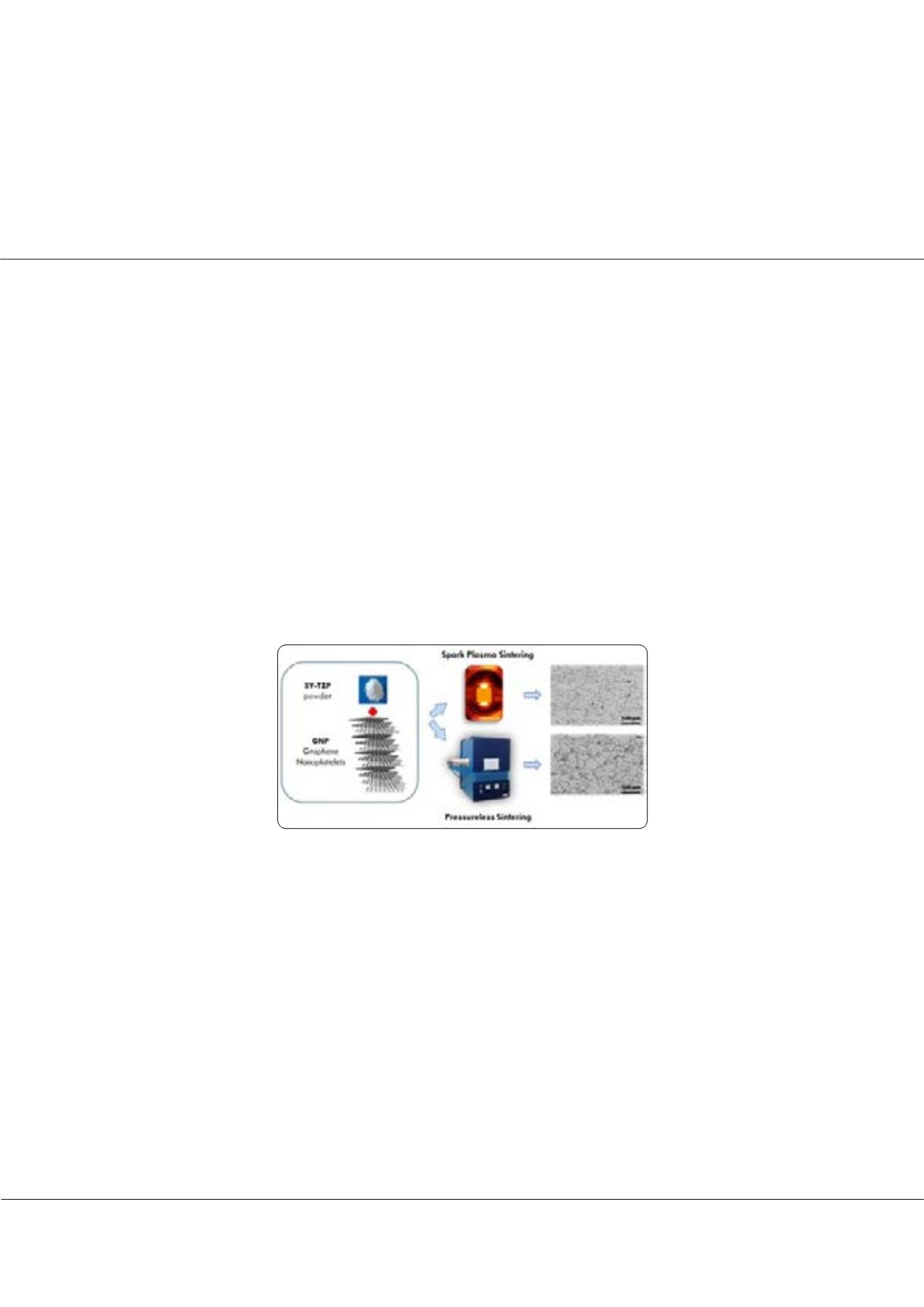

Role of sintering method on graphene/3YTZP composites

C. López-Pernía, R. Poyato, A.Morales-Rodríguez

and

A.Gallardo-López

Universidad de Sevilla, Spain

G

raphene in the form of graphene nanoplatelets (GNP), graphene oxide or few layer graphene has become an ideal filler

in fabrication of different polymer, metal or ceramic composites. Recently, the fabrication of ceramic matrix composites

with graphene-based materials has attracted a special interest due to the potential improvement of mechanical and functional

properties. Amongst ceramic matrices, 3 mol% yttria tetragonal zirconia (3YTZP) presents outstanding mechanical properties

and with the addition of GNP can become electrically conductive. The properties of the materials depend not only on the

composition, but also on the microstructure. In the case of ceramics, the processing method has a great importance from the

point of view of the final properties. Graphene / ceramic composites are typically prepared through wet powder processing

followed by a pressure assisted sintering technique, such as Spark Plasma Sintering (SPS) or Hot Pressing (HP). SPS advantages

over HP include lower sintering temperatures and shorter sintering times. However, it requires expensive equipment and

produces highly anisotropic materials. Conventional pressureless sintering (PLS) is a simpler and cheaper sintering method

that produces composites with lower anisotropy. Therefore, the study of graphene / ceramic composites prepared by PLS

compared to SPS sintered ones is very interesting. The main objective of this work is to make a direct comparison of the

effects of these two sintering techniques (PLS and SPS) on the microstructural features, mechanical and electrical properties of

composites of 3YTZP with different contents of GNPs.

Recent Publications

1.

L. S. Walker, V. R. Marotto, M. A. Rafiee, N. Koratkar, and E. L. Corral, “Toughening in Graphene Ceramic Composites,” ACS

Nano, vol. 5, no. 4, pp. 3182–3190, 2011.

2.

S. Ramesh, M. Mohaymen Khan, H. C. Alexander Chee, Y. H. Wong, P. Ganesan, M. G. Kutty, U. Sutharsini, W. J. Kelvin Chew,

and A. Niakan, “Sintering behaviour and properties of graphene oxide-doped YTZP ceramics,” Ceram. Int., vol. 42, no. 14,

pp. 17620–17625, 2016.

3.

A. Gallardo-López, I. Márquez-Abril, A. Morales-Rodríguez, A. Muñoz, and R. Poyato, “Dense graphene nanoplatelet/yttria

tetragonal zirconia composites: Processing, hardness and electrical conductivity,” Ceram. Int., vol. 43, no. 15, pp. 11743–

11752, Oct. 2017.

4.

C. Ramirez, P. Miranzo, M. Belmonte, M. I. Osendi, P. Poza, S. M. Vega-Diaz and M. Terrones."Extraordinary toughening

enhancement and flexural strength in Si3N4composites using graphene sheets".J. Eur. Ceram. Soc.,34,pp. 161–169,

2014.Gg5.

F. Chen, D. Jin, K. Tyeb, B. Wang, Y. H. Han, S. Kim, J. M. Schoenung, Q. Shen, and L. Zhang, “Field assisted sintering of

graphene reinforced zirconia ceramics,” Ceram. Int., vol. 41, no. 4, pp. 6113–6116, 2015.

Biography

Cristina López Pernía is a doctoral candidate at the Department of Condensed Matter at Universidad de Sevilla. She graduated with a Bachelor of Materials Engineering from Universidad

Politécnica de Madrid and holds a Master’s Degree in

Advanced Materials

from Universidad Autónoma de Madrid. Currently she focuses her work on graphene-ceramic composites.

cristinalopez@us.esC. López-Pernía et al., Res. Rev. J Mat. Sci. 2018, Volume 6

DOI: 10.4172/2321-6212-C1-014