ISSN:2321-6212

ISSN:2321-6212

Department of Physics, Khulna University of Engineering & Technology, Khulna, Bangladesh

Received Date: 18/10/2017; Accepted Date: 06/11/2017; Published Date: 12/11/2017

DOI: 10.4172/2321-6212.1000202

Visit for more related articles at Research & Reviews: Journal of Material Sciences

FINEMET-like amorphous ribbon of composition (Fe0.95Co0.05)73.5Cu1N b3Si13.5B9 was prepared by rapid quenching method in an Argon (Ar) atmosphere. The alloy has been annealed in a controlled way in the temperature range of 550 to 750°C for 30 minutes. Nanocrystalline state was evaluated by X-ray diffraction (XRD). In the range of annealing temperature (Ta), the grain size has been found in the range of 9-26 nm. Frequency dependence of permeability of amorphous and nanocrystalline toroid shaped samples have been measured. The low frequency initial permeability for the optimum annealed samples has been found to 5.8 × 103 and the highest value of quality factor is found for the sample annealed at 550°C; which also indicates the best heat treatment temperature.

Annealing temperature, Grain size, Complex permeability, Relative quality factor

Over the past several decades, amorphous and most recently, research interest in nanocrystalline soft magnetic alloys has dramatically increased. Soft magnetic materials face demanding requirements for high performance electronic and power distribution systems. With the reduction of size into nanometer range, the materials exhibit interesting properties including physical, chemical, magnetic and electrical properties compare to conventional coarse grained counterparts. Soft magnetic nanostructured materials have a number of potential technological applications [1-11]. Nanocrystalline soft magnetic materials were first reported in 1988 by Yoshizawa et al. [12] through controlled crystallization of Fe-Si-B amorphous alloys with the addition of copper (Cu) and niobium (Nb). The development of nanocrystalline Fe-Si-B-Nb-Cu alloys, commercially known as FINEMET, established a new approach to develop soft magnetic materials. The nanocrystalline state is achieved by subsequent heat treatment from their as cast amorphous precursor above the primary crystallization temperature. Excellent soft magnetic properties can be found in nanocrystalline materials of Fe-Si-B amorphous ribbons containing Cu and Nb. The addition of Cu and Nb results in the formation of an ultra-fine grain structure. The main purpose of this research is to determine empirically the optimum annealing temperature, corresponding to maximum permeability, constancy of permeability and maximum frequency range over which the sample can be used as a soft magnetic material.

The amorphous ribbon with a composition (Fe0.95Co0.05)73.5Cu1Nb3Si13.5B9 was prepared from high purity Fe (99.9%), Co (99.9%), Nb (99.9%), Si (99.9%), Cu (99.9%) and B (99.9%). The ribbons were produced in an arc furnace on a water-cooled copper

hearth by a single roller melt-spinning technique under an atmosphere of pure Ar at the Centre of Materials Science, National

University of Hanoi, Vietnam. The wheel velocity was about 34 m/s. The ribbons were annealed in a vacuum heat treatment

furnace at 550, 600, 625, 650, 675, 700, 725 and 750°C respectively for constant time 30 minutes and then cooled down to

the room temperature. Amorphousity of the ribbon and nanocrystalline structure has been observed by XRD (Philips (PW 3040) X

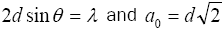

‘Pert PRO XRD) with Cu-Kα radiation. Lattice parameter (a0) were calculated using equations  , where

λ = 1.54178Å for Cu −Kα radiation. Grain size (Dg) of all annealed samples of the alloy composition has been determined using Debye-Scherrer method [13]. Si contents were calculated using the equation:

, where

λ = 1.54178Å for Cu −Kα radiation. Grain size (Dg) of all annealed samples of the alloy composition has been determined using Debye-Scherrer method [13]. Si contents were calculated using the equation:  , where X is at.% Si in the nanograins. The

frequency characteristics i.e. the initial permeability spectra of the toroid shaped samples were measured using an impedance

analyzer (model no. 6500B) at room temperature in the frequency range 1 kHz to 13 MHz. The real part of complex permeability

(μ') was calculated using relation, μ'=L/Lo, where L is the self-inductance of the sample and Lo is the inductance of the coil of same

geometric shape of vacuum. Lo is determined using the relation, Lo=μoN2S/πd, where μo is the permeability of the free space, N is

the number of turns (here N=10), S is the area of cross-section

, where X is at.% Si in the nanograins. The

frequency characteristics i.e. the initial permeability spectra of the toroid shaped samples were measured using an impedance

analyzer (model no. 6500B) at room temperature in the frequency range 1 kHz to 13 MHz. The real part of complex permeability

(μ') was calculated using relation, μ'=L/Lo, where L is the self-inductance of the sample and Lo is the inductance of the coil of same

geometric shape of vacuum. Lo is determined using the relation, Lo=μoN2S/πd, where μo is the permeability of the free space, N is

the number of turns (here N=10), S is the area of cross-section  , where m is the weight of the ribbon, d and ρ are the mean

diameter and density of the sample. The imaginary part of complex permeability (μ'') was determined using the formula μ''=μ' × D.

The relative quality factor was calculated from the Loss factor, tanδ (tan δ=μ″/μ′) using the relation μ′Q=μ′/tan δ.

, where m is the weight of the ribbon, d and ρ are the mean

diameter and density of the sample. The imaginary part of complex permeability (μ'') was determined using the formula μ''=μ' × D.

The relative quality factor was calculated from the Loss factor, tanδ (tan δ=μ″/μ′) using the relation μ′Q=μ′/tan δ.

XRD

XRD spectra of as-cast and annealed at 550 to 750°C for 30 minutes have been presented in Figure 1. One broad peak at 2θ=45° for the as-cast sample confirms the amorphous state. XRD pattern clearly indicates the formation of bcc α-FeCo(Si) phase at Ta=550°C or above with the appearance of (110), (200) and (211) fundamental diffraction peaks. With the increase of Ta, (110) peak becomes sharper which means the grains are growing bigger. From the Figure 1 it is also observed that just before (110) peak, another diffraction line with small peak at 2θ≈44° appeared for the samples annealed at 700 to 750°C. This diffraction peak has been matched with Fe23B6 phase (boride phase).

This is because, with increasing Ta the diffusion of Si into α-FeCo space lattice increases and hence increases the formation of α-FeCo(Si) nanograin. At higher Ta, Si diffuses out of nanograins due to recrystallization corresponding to formation of boride phase which is consistent with the result of other FINEMET’s [14]. Absence of boride phase in the XRD spectra is possibly due to very small volume fraction of Fe23B6. Figure 2 shows the variation of Dg of α-FeCo(Si) phase with Ta. Enhancement of Dg with Ta complies with the reported result [15]. All the results of θ, d-values, FWHM, a0, Dg and Si-content from XRD analysis are listed in Table 1.

Table 1. The values of θ, d-values, a0, FWHM, Si-content and Dg with respect to Ta of (Fe0.95Co0.05)73.5Cu1Nb3Si13.5B9 alloy.

| Ta(°C) | θ(degree) | d(Å) | a(Å) | FWHM | Si(at%) | Dg(nm) |

|---|---|---|---|---|---|---|

| 550 | 22.6188 | 2.0044 | 2.8347 | 0.93 | 21.14 | 9 |

| 600 | 22.6343 | 2.0031 | 2.8328 | 0.83 | 22 | 10 |

| 625 | 22.6438 | 2.0023 | 2.8317 | 0.81 | 22.5 | 10 |

| 650 | 22.6355 | 2.0030 | 2.8327 | 0.75 | 22.05 | 11 |

| 675 | 22.6021 | 2.0058 | 2.8367 | 0.69 | 20.23 | 13 |

| 700 | 22.5701 | 2.0085 | 2.8404 | 0.45 | 18.55 | 19 |

| 725 | 22.5145 | 2.0132 | 2.8471 | 0.41 | 15.5 | 22 |

| 750 | 22.4791 | 2.0162 | 2.8514 | 0.33 | 13.55 | 26 |

Complex Permeability

Figure 3 shows the frequency dependence of the μ/ for as-cast and the samples annealed at temperature 550 to 700°C for a constant annealing time of 30 minutes. From the figure it is observed that the low frequency value of μ/ increases with the increase of Ta and attains the maximum value at 550°C. A sharp increase of μ/ is found due to crystallization of α-FeCo(Si) phase. When the Ta is higher than 550°C, μ/ decreases rapidly. At higher Ta, the decrease of μ/ may be attributed to the stress developed in the amorphous matrix by growing crystallites. The newly grown crystallites serve as pinning centers at which domain walls are pinned and creates obstructions for their mobility resulting in a decrease in μ/.The evolution of boride phases and the nonmagnetic fcc phases including Cu clusters leads to the increase of magnetocrystalline anisotropy to a high value, as a result of which magnetic hardening takes place [16]. The general characteristic of the curve is that μ/ remains fairly constant up to some critical frequency characterized by the onset of resonance connected with the loss component. At critical frequencies, μ/ drops rapidly.

The frequency dependent imaginary part of the complex initial permeability (μ//) annealed at different temperatures at constant annealing time 30 minutes are shown in Figure 4. These results are quite complimentary to the results of the real part of the complex permeability of samples. After critical frequencies the μ// increases with increasing frequency. The high value of μ// for the samples corresponds to high loss factor as shown in Figure 3. The origin of the loss factor can be attributed to various domain effects [17], which include non-uniform and non-repetitive domain wall motion, domain wall bowing, localized variation of flux densities and nucleation and annihilation of domain walls.

Relative Quality Factor

The frequency dependence of relative quality factor (μ/Q) of the sample annealed at different temperatures is shown in Figure 5. From the figure it is observed that the μ/Q initially rises with increasing frequency and reaches a peak value. Beyond the peak value, the μ/Q is found to decrease. It is also found that the μ/Q increases with the increase of Ta up to 550°C and with further increase of Ta the μ/Q decreases. At high frequency, the flux penetration becomes low, as a result the loss is mainly controlled by interaction between the grains of the alloy but at very low frequency the loss is controlled by hysteresis losses. The decrease of μ/Q with increasing Ta after 550°C is due to increase of Dg for the precipitation of Fe borides [16]. The precipitation of very small percent of particles increases the high frequency losses. The highest value of μ/Q is found for the sample annealed at 550°C, which also indicates the best heat treatment temperature. From all curves, it is noted that the higher values of the μ/Q in general lie within the frequency range of 10 kHz to 100 kHz. Thus the frequency range for application area might be chosen.

Nanocrystalline amorphous ribbon of the FINEMET family with a nominal composition (Fe0.95Co0.05)73.5Cu1Nb3Si13.5B9 has been studied. The amorphous state of the as-cast amorphous ribbons has been confirmed by XRD. The evolution of nanocrystallites of α-FeCo(Si) with Ta have been confirmed from the fundamental diffraction peaks. The grain size of the sample was found from 9 to 26 nm. The maximum μ/ is observed for the sample annealed at 550°C. A sharp increase of μ/ at this temperature is due to the formation of nanometric α-FeCo(Si) grain. The highest value of μ/Q is achieved for the sample annealed at 550°C in the frequency range 10 kHz to 100 kHz. So, 550°C is the most suitable heat treatment temperature from the application point of view in case of the present alloy as a soft magnetic material.

We are grateful to Bangladesh Council for Scientific and Industrial Research (BCSIR) and Materials Science Division, Atomic Energy Centre, Dhaka (AECD) for giving experimental facilities and cordial co-operations.