ISSN:2321-6212

ISSN:2321-6212

Du Xiaoming*, Li Siyu, Wang Yan, Sun Zhendong

Department of Materials Science and Engineering, Shenyang Ligong University, Shenyang 110159, China

*Corresponding Author:

Received: 28-Jun-2024, Manuscript No. JOMS-24-140147; Editor assigned: 02-Jul-2024, PreQC No. JOMS-24-140147 (PQ); Reviewed: 16-Jul-2024, QC No. JOMS-24-140147; Revised: 07-May-2025, Manuscript No. JOMS-24-140147 (R); Published: 14-May-2025, DOI: 10.4172/2321-6212.13.2.002

Citation: Xiaoming D, et al. Effect of Interface on Thermal Conductivity of Graphene-Reinforced Aluminum Matrix Composites. RRJ Mater Sci. 2025;13:002.

Copyright: © 2025 Xiaoming D, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution and reproduction in any medium, provided the original author and source are credited.

Visit for more related articles at Research & Reviews: Journal of Material Sciences

The thermal conductivity of graphene-bolstered aluminum-based composites become numerically investigated the usage of the finite detail approach. First of all, the impact of graphene content, morphology, and orientation on the thermal conductivity of the composite fabric become studied without interfaces. After obtaining the most suitable parameters without interfaces, the outcomes of interface kinds and interface thickness have been similarly investigated. The simulation results verified that the thermal conductivity of the composite material advanced with increasing graphene content material and particle length. The thermal conductivity reached its maximum cost while the orientation of the graphene turned into parallel to the path of warmth drift. While the thermal conductivity of the interface material changed into more than that of the matrix, The thermal conductivity of the composite cloth accelerated more rapidly with growing thickness. Conversely, while the thermal conductivity of the interface material changed into decrease than that of the matrix, a smaller intrinsic thermal conductivity resulted in a quicker decline within the thermal conductivity of the composite material with growing thickness. This examine famous that the amendment of graphene plays a vital role in regulating the thermal conductivity of aluminum matrix composites.

Aluminum matrix composites; Graphene; Thermal conductivity; Interface

With the speedy improvements within the electronics enterprise, the complexity of digital devices has substantially multiplied. As a quit result, those devices generate an enormous quantity of warmth inner an exceptionally brief span of time. Failure to dissipate this heat right away may have damaging effects at the durability of digital merchandise. For this reason, it's far critical to develop digital packaging materials that show off great thermal conductivity [1-3]. One such material of hobby is aluminum, a metal substance recognised for its advanced properties along with its lightweight nature and wonderful mechanical characteristics, when in comparison to opportunity substances. Moreover, graphene is a cloth with thermal switch characteristics. Because of its particular carbon atomic shape and the quick thermal conductivity facilitated through its unfastened electrons, graphene an extremely good thermal conductivity. Moreover, graphene demonstrates wonderful thermal balance and a low thermal expansion coefficient, permitting it to carry out particularly nicely in excessive-temperature environments and under speedy temperature fluctuations. This has brought about enormous studies at the aggregate of graphene with aluminum matrices, ensuing inside the improvement of graphene-reinforced aluminum matrix composites [4].

Numerous studies have highlighted numerous fantastic troubles associated with this unique composite fabric. Firstly, there's a loss of adequate wetting some of the graphene and the aluminum matrix, ensuing within the formation of cracks, voids, and distinct defects at the interface in the course of low-temperature fabrication. This hinders the powerful bonding the various additives and in the long run influences the general performance of the composite. Moreover, when the fabric is subjected to high temperatures throughout instruction, the graphene debris react with the aluminum matrix, leading to the creation of an interface product referred to as Al4C3. Al4C3 possesses low thermal conductivity and high brittleness and is prone to reaction and degradation inside the presence of water. If a sizable quantity of Al4C3 accumulates on the interface, it could purpose cracking, thereby substantially impacting the performance of the composite material. To deal with the aforementioned problems, two improvement strategies had been developed, particularly matrix alloying and surface metallization of reinforced stages [5-8]. But, the effectiveness of matrix alloying is regularly brought on by means of using the sintering approach and the amount of alloying elements, making it difficult to constantly gain the preferred consequences. Therefore, in practical applications, bodily or chemical techniques are frequently employed to alter the ground by using way of utilizing a transition layer over the reinforcing segment. As an example, Zhang et al. located that preplating and sintering extensively decorate the wettability of the diamond-copper interface and decorate thermal conductivity. While a 110 nm thick W coating is carried out, the thermal conductivity of the diamond/copper composite cloth reaches 910 W/(m•okay) [9]. Jia et al. applied electroless plating to deposit a 0.5 μm thick Cu layer on the floor of graphite fibers and decided that thru enhancing the bonding potential the various graphite fibers and the aluminum substrate, the thermal conductivity of the composite fabric reached 208 W/(m•ok), that is a seventy 7% boom compared to the uncoated country [10]. Zeng et al. employed a salt bathtub approach to floor coat graphite flakes with Si and add a copper mesh. Then, they employed vacuum warm urgent to fabricate the graphite/Al composite. The outcomes indicate the presence of exceedingly aligned graphite ribbons inside the composite, developing pathways for more thermal conductivity [11].

At gift, there may be currently no precise analytical concept to be had for reading the impact of interface form and properties on the thermal houses of composite materials. Historically, studies on the thermal conductivity of materials have trusted sample instruction and subsequent detection. In evaluation, the usage of finite detail simulation calculations not excellent reduces costs and shortens the studies and improvement cycle however additionally enables the exploration of a greater diversity of issues which can be commonly impossible thru actual experiments, which include excessive situations. This method holds exquisite significance in the examination of material houses [12].

On this examine, we hire finite element techniques to numerically simulate graphene-strengthened aluminum-based totally completely composite substances. First off, the have an effect on of graphene content material, morphology, and orientation at the thermal conductivity of the composite material modified into investigated. Finally, the modulation mechanisms of interface types and interface thickness had been in addition studied after acquiring advanced parameters without interfaces via the analysis of simulation consequences, we optimize the microstructure of the composite materials, thereby laying a theoretical basis for the layout of high thermal conductivity composite substances. The findings pave the manner for the development of mild-weight and noticeably efficient thermal management answers, advancing technological progress in severa fields.

Heat conduction mechanism and simulation methods

Heat conduction mechanism: The essential mechanism of warmth conduction includes the exchange of energy between particles via collision, without any net fabric displacement. Inside the case of metals and alloys, unfastened electrons are critical providers of warmth conduction. Due to their quite small mass, warmness conduction heavily is predicated on the mobility of unfastened electrons. Because of their incredibly low mass, electrons possess the capacity to swiftly transfer thermal electricity. Conversely, in graphene particles, heat conduction mostly happens via phonons. As a warmness modern-day traverses a single fabric, the temperature gradient undergoes non-stop changes. The fantastic molecular or lattice systems of various substances bring about varied vibrational frequencies for phonons and electrons. Consequently, at fabric interfaces, warmth waft stories scattering, leading to power dissipation and discontinuous temperature variations [13], as proven in Figure 1. This phenomenon manifests as interfacial thermal resistance that is dictated with the aid of the interplay among warmness flux and temperature distinction. The relationships among them are as follows:

Where, in Q is the warmth flux, ΔT is the temperature distinction among the bloodless and heat ends, and Rk is the interface thermal resistance.

Figure 1. Simulated temperature nephogram of graphene-reinforced aluminum matrix composites (a) and single material.

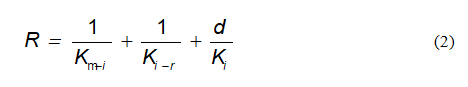

For the characterization of multilayer interface structures, the DMM (Diffuse Mismatch version) is usually used to estimate interfacial thermal conductivity. This precept assumes that incident phonons revel in diffusion and elastic scattering on the interface, and the general thermal resistance of the composite fabric consists of three additives: The thermal resistance most of the matrix and the interface layer, the thermal resistance a number of the interface layer and the reinforcing segment, and the thermal resistance of the interfacial layer itself [14,15]. And, the reciprocated of the interfacial thermal conductivity appear for the interface thermal resistance. The general thermal resistance of the composite material may be mathematically expressed as follows:

In which R is the entire thermal resistance, d is the interface thickness, Km-i is the thermal conductivity among the substrate and the interface layer, Ki-r is the thermal conductivity between the interface layer and the reinforcing section, and Ki is the thermal conductivity of the interface cloth.

Simulation methods: To make sure the reliability of finite cloud simulations, the simulation evaluation manner consists of several vital measures. First of all, the geometric version is meticulously crafted to seize the problematic microstructural features of the composite material accurately. Secondly, the mesh is finely divided to strike a sensitive balance between computational accuracy and feasibility. It ensures precise calculations while maintaining optimal computational efficiency. Lastly, a giant number of simulation cases are accomplished to set up a stable and constant thermal conductivity coefficient for the composite material. These meticulous steps guarantee the accuracy of the effects received from the finite cloud simulations. A three-dimensional microscopic model of graphene-strengthened aluminum matrix composites with a volume fraction of 1% and aside duration of 1 mm has been built. A uniform continuous interfacial layer is uniformly established on the surface of the graphene particles, and the reinforced graphene particles, the aluminum matrix, and the interfacial phase are in an ideal state of combination. The thermal conductivity of the aluminum matrix and interface material is isotropic in the course of the simulation, whilst the graphene reinforcing phase is anisotropic. In order to streamline computational processes, the geometric model of composite materials incorporates the following assumptions:

• The composite fabric is thought to be completely dense, without any gaps or cracks.

• The interface segment is considered a homogeneous and natural substance.

• The reinforcing section particles are assumed to own everyday shapes and are randomly distributed inside thematrix, without any adhesion to each different.

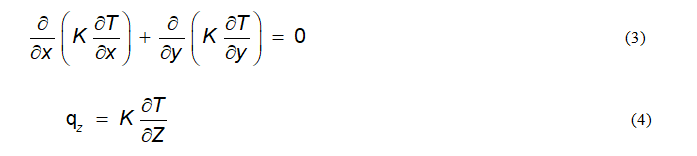

Whilst accomplishing constant-state heat conduction analysis, the outcomes of heat convection and heat radiation on temperature and warmth flux density are ignored, and the temperature at any node within the simulation procedure does no longer exchange with time. In this situation, the temperature and heat flux densities satisfy the subsequent equations [16-18]:

Where, in K is thermal conductivity, T is temperature, and q is warmness flux density. As depicted in Figure 2, varied temperature loads are imposed on the top surface (Z=L) and backside floor (Z=0) alongside the route of the Z-axis. The X-axis and Y-axis instructions, however, exhibit insulated boundary conditions.

Via the use of finite element software program, it turns into feasible to generate temperature and heat flux density nephograms for composite substances. The ones nephograms permit the visualization of the distribution of temperature and heat flux density distributions. The average warmth flux density may be calculated via simulating the calculation of the cost of the warmth flux density at character nodes as soon as the mesh has been partitioned into sections. Finally, this common warmness flux density may be substituted into Fourier's regulation to derive the powerful thermal conductivity of graphene-strengthened aluminum matrix composites [19].

Where qavg is the average heat flux density, L is the distance between the high and low temperature ends, and ΔT is the temperature difference between the high and low temperature ends.

Figure 2. Boundary conditions of the thermal conduction simulation model.

Effect of graphene content

Figure 3 presents a comparison among finite detail simulation consequences and experimental take a look at effects of thermal conductivity for the composite materials at one-of-a-kind graphene contents. As proven in Figure 3, both strategies indicate a growing fashion within the thermal conductivity of the composite fabric with growing graphene content material. But, the finite detail simulation technique determines a linear correlation between graphene content material and thermal conductivity of the composite fabric, and that's common better than the experimentally examined outcomes. There are mainly motives for this phenomenon: To start with, the finite element simulation method simplifies and idealizes complicated material systems and boundary conditions, probably overlooking the have an effect on of certain microscopic factors. Those factors encompass defects, crystal systems, and many others. Which can also have an extensive effect on thermal conductivity all through actual experiments, but are not absolutely considered within the simulation. Secondly, finite element simulation is primarily based on a series of cloth parameters consisting of thermal conductivity, density, and temperature-associated parameters. If the parameters used within the simulation vary from the real fabric homes, it can cause discrepancies among the calculated thermal conductivity and experimental effects. The thermal conductivity of the pure aluminum matrix received thru powder metallurgy training regularly does no longer reach 237 W/(m•okay). Consequently, underneath the combined have an effect on of the aforementioned motives, there exists a discrepancy between the finite detail simulation outcomes and the experimental check results of thermal conductivity for the composite materials.

Furthermore, as shown in Figure 3, while the graphene content increased from 0% to 0.3%, 0.5%, 0.75% and 1%, the thermal conductivity of the composite improved by 5.13%, 11.09%, 13.27% and 15.69%, respectively. To sum up, while the graphene content material reaches 0.3%, the growth charge of the thermal conductivity of the experimentally examined composite fabric tremendously slows down with increasing graphene content material. That is because at better graphene contents, graphene debris may also typically generally tend to mixture and form graphene clusters with voids present between the clusters, which prevent warm temperature conduction. In addition, at decrease graphene contents, the compatibility between graphene particles and the aluminum matrix is better, which enhances the effectiveness of thermal conduction. And, as the graphene content increases, the interplay among graphene debris and the aluminum matrix may reduce their compatibility, affecting the increase fee of the thermal conductivity. Although, typical, the change tendencies from both finite detail simulation results and experimental check consequences are consistent, indicating that the simulation outcomes can appropriately predict the thermal conductivity of composite materials. Therefore, the finite detail simulation method can remain used inside the have a look at of the thermal conductivity of graphene-strengthened aluminum-based composite materials in subsequent studies.

Figure 3. Comparison between finite element simulation results and experimental test results of thermal conductivity for the composite materials at different graphene contents.

Impact of graphene orientation

Figure 4 illustrates the thermal conductivity of the composite fabric with various graphene content material and orientation angles ranging from 0° to 105°. The thermal conductivity of the composite fabric well-known shows an exciting behavior with respect to the orientation attitude within the range of 0° to 60°. In this variety, the thermal conductivity decreases as the angle increases. Furthermore, in the range of 60° to 90°, the decrease in thermal conductivity will become even greater stated. However, because the perspective continues to growth beyond 90°, the thermal conductivity begins to reveal an increasing fashion once more. To demonstrate this, don't forget the case of a graphene volume fraction of 1%. when the heat flow course aligns parallel to the graphene plane (i.e., an orientation attitude of 0°), the composite fabric achieves its most thermal conductivity, exhibiting a substantial 36.35% growth in comparison to the bottom fabric. Due to the fact the orientation mindset will increase, the thermal conductivity grade by grade decreases. While the heat go with the flow direction aligns perpendicular to the graphene plane (i.e., an orientation attitude of 90°), the thermal conductivity reaches its minimal fee, experiencing a 6.74% decrease as compared to the base fabric. Significantly, at the same time as the orientation mindset of graphene falls in the style of 60° to one 105°, the overall thermal conductivity of the composite cloth is decrease than that of a pure aluminum base. Throughout this range, the presence of graphene as a reinforcing segment acts detrimentally, failing to enhance the thermal conductivity of the composite cloth. This conduct may be attributed to the two-dimensional houses of graphene, which bring about distinctly robust anisotropy in thermal conductivity ordinary performance. Specifically, the thermal conductivity within the plane course can range from 3000 W/(m.ok) to 5300 W/(m.good enough), displaying a 10 to at the least one hundredfold boom as compared to the thermal conductivity inside the vertical direction to the aircraft.

Figure 4. Thermal conductivity of composites with different graphene content and orientation.

In concept, specific control over the orientated distribution of graphene within the aluminum base can considerably beautify the thermal conductivity normal performance of the composite cloth. Consistent with this perception, a look at conducted by way of Xiao Min and his team found that vertically aligned graphene can fully make the most the exquisite houses of unmarried-layer graphene, including high thermal conductivity and carrier mobility [20]. Wu et al. efficiently changed graphene via chemical bonding, acquiring magnetic graphene. With the aid of utilizing a magnetic discipline-induced approach, they dispersed the magnetic graphene within an epoxy resin matrix to create an oriented graphene/epoxy resin encapsulation cloth. Experimental consequences showed that the thermal conductivity of the composite fabric elevated with the augmented content material of magnetic graphene, ensuing in an outstanding 54.8% development compared to epoxy resin on my own [21]. Those studies findings align with the simulation consequences offered in this text, indicating the treasured insights that finite detail simulation evaluation can offer for calculating the thermal conductivity of composite substances. Consequently, it's miles encouraged to align the graphene parallel to the heat glide course during experimental instruction to absolutely harness the excessive thermal conductivity of graphene and attain the maximum thermal conductivity of the composite material.

Impact of graphene length

The thermal conductivity of composite substances containing graphene particles of various sizes is illustrated in Figure 5. Evaluation of the plotted facts well-knownshows a widespread trend of increasing thermal conductivity because the graphene particle length will increase. Specially, an almost linear dating is discovered while the graphene particle length levels from 13 μm to 19 μm, with an approximate four.8% boom in thermal conductivity. Moreover, whilst the graphene particle size similarly will increase from 19 μm to 21 μm, the thermal conductivity suggests a vast increase of approximately.

7.9%. The exceptional enhancement in thermal conductivity may be attributed to the surface electricity and neighboring coordinating atoms of the graphene particles. When the volume fraction stays steady, smaller graphene particles own better floor energy and less coordinating atoms on their surfaces, ensuing in a volatile state. Consequently, the graphene particles generally tend to aggregate, which hinders their dispersion inside the aluminum matrix. No matter the intrinsic high thermal conductivity of graphene, particle aggregation prevents the formation of a powerful thermal network in the composite fabric. Thus, the thermal conductivity of graphene-reinforced aluminum-primarily based composites fails to satisfy the anticipated overall performance.

Figure 5. Thermal conductivity of composites with different graphene particle sizes.

In line with the effective medium concept, the size of graphene particles plays an essential position in figuring out interfacial thermal resistance. Whilst thinking about the equal extent fraction, the dimensions of particles without delay affects the unit quantity surface location. Smaller particle sizes result in a higher wide variety of particles, large unit extent floor area, and extended hindrance to warmth drift. Therefore, this results in lower thermal conductivity in the composite material. Moreover, studies have revealed that thermal conductivity is proportional to the logarithm of the effective length of graphene alongside the direction of heat glide. This courting is linked to the 2-dimensional residences of graphene and the thermal conduction of low-frequency phonons in graphene. Due to the fact the particle length of graphene will boom, more low-frequency phonons come to be excited and make contributions to the thermal conduction technique. Ding et al. carried out a take a look at that tested a discounted quantity of interfaces concerned in warmth switch as the particle size of the reinforcing phase accelerated. This reduction in interfaces positively impacts the general thermal conductivity of the composite fabric [22]. Some other observe through Yu et al. focused on graphene/epoxy resin-based composites organized the use of a solution mixing approach. They determined that the thermal conductivity of the composite cloth decreases with decreasing graphene particle length. However, in addition growing the particle size consequences in non-uniform distribution and vast variations in thermal conductivity between the upper and decrease surfaces of the samples [23].

The observed trend of the simulated composite material with varying graphene particle size in this study aligns with the findings of the aforementioned research, validating the accuracy of the finite element simulation analysis. It is important to note that increasing the size of graphene particles may lead to a decline in the mechanical properties of the composite material. Graphene itself has low strength, and as the size of graphene particles increases, cracks can propagate along the interlayer of flake-like graphite, thereby reducing the overall strength of the composite material. This aspect should also be considered in material design.

Effect of interface material types

Figure 6 shows the thermal conductivity of graphene-reinforced aluminum matrix composites with different interfacial materials. It's far observed that the intrinsic thermal conductivity of those six interface substances follows the collection of Ag>Cu>W>Mo>Cr>Ni. Therefore, the thermal conductivity of the composite substances reveals a comparable sample because the interfacial materials are delivered. When the microstructure factors of graphene are the same, the equivalent thermal conductivity of the composite is 294.05 W/(m•K) without interface. Notably, only the interface materials Ag and Cu, which possess higher thermal conductivity than the aluminum matrix, were able to improve the thermal conductivity of the composite material, by 16.85% and 13.5% respectively. However, when the interface materials are W, Mo, Cr, and Ni, the thermal conductivity of the composite material decreases by 7.8%, 12.8%, 18.26%, and 21.42% respectively.

Figure 6. Thermal conductivity of composite materials with different interface types.

As displayed in Figure 7, the red region indicates areas with high heat flux density, while the blue region represents areas with low heat flux density. The maximum heat flux density mostly concentrates within and across the graphene particles, setting up a non-stop heat go with the flow channel characterised by using high warmness flux density values. The interface area transitions from pink to blue in correlation with the growing thermal conductivity of the interfacial cloth. This phenomenon arises from the principle of minimum thermal resistance governing heat conduction, causing heat to preferentially flow towards regions with relatively lower thermal resistance. As depicted in Figure 8a, when heat travels through the Ag interface layer from the matrix to the reinforcement phase, there is almost no scattering phenomenon. In addition, a significant accumulation of heat flow is observed near the graphene particles, indicating that the addition of the Ag interface layer has almost no harmful effect on the entire heat transfer process. In contrast, the thermal conductivity of Ni is 64.9 W/(m•K), significantly lower than that of the matrix aluminum and the graphene reinforcement. As illustrated in Figure 8b, severe scattering occurs as heat traverses the interface layer, with instances of backflow observed. During the warmth transfer system, a fragment of the heat float bypasses the interface layer, at the same time as most effective a small fraction manages to penetrate the interface phase and input the interior of the graphene debris. As a result, graphene’s superior thermal conductivity cannot be fully utilized. In addition, this bypassing phenomenon elongates the heat transfer path, combining with these two factors to diminish the thermal conductivity of the aluminum-based composite material.

Figure 7. Heat flux nephogram of composite material with different interface types of Ag (a) and Ni (b).

Figure 8. Heat flux vector nephogram of composite material with different interface types of Ag (a) and Ni (b).

From the above discussion, it can be concluded that the relationship between the thermal conductivity of the interface layer material and the matrix material has a significant impact on the thermal performance of graphene-reinforced aluminum-based composite materials. In addition to the intrinsic thermal conductivity of the interface material, the presence of the interface introduces interface thermal resistance, which disrupts or restricts the heat conduction pathway, thereby reducing the overall thermal conductivity. Energy scattering and reflection at the interface also have adverse effects on heat conduction. Moreover, there is an inverse relationship between interface thermal resistance and interface thermal conductivity. Therefore, the smaller the intrinsic thermal conductivity of the interface layer material, the larger the interface thermal resistance. When heat flows through, the interface layer exhibits stronger obstruction and scattering capabilities, resulting in a greater reduction in the thermal conductivity of the composite material.

Effect of interface material thickness

Figure 9 depicts the equivalent thermal conductivity of graphene-reinforced aluminum matrix composites featuring various interface materials and interface thicknesses ranging from 1 μm to 5 μm. As the interface thickness increases within this range, the thermal conductivity of Ag and Cu as interface materials demonstrates respective improvements of 5.87% and 5.32%. Conversely, when using W, Mo, Cr, and Ni as interface materials, the thermal conductivity experiences reductions of 8.55%, 10.68%, 12.12%, and 15.93% respectively. As the interface layer thickness expands, the interface thermal resistance generated by the interface layer regularly assumes a dominant position in the standard thermal resistance, particularly in interface layers offering low intrinsic thermal conductivity. Equation (2) implies that the smaller thermal conductivity of the interface cloth leads to greater extraordinary thermal resistance with elevated interface thickness, resulting in an extra speedy decline within the thermal conductivity of the composite fabric. Although Cu and Ag can improve the thermal conductivity of the composite material as interface materials, it is not advisable to blindly increase the interface thickness in practical applications. This is due to the reaction between graphene and the interface material at elevated temperatures, which leads to the formation of carbide. Typically, carbide exhibits a thermal conductivity that is one to two orders of magnitude lower than that of the interface material, the matrix material, and graphene. Additionally, during the reaction process, atomic diffusion occurs, resulting in the formation of voids at the interface due to the Kirkendall effect, further reducing the thermal conductivity of the composite material. However, it is important to note that there is a practical limit to the thickness of the interface. With extremely thin interface layers, there may not be a complete interface to effectively transfer heat, subsequently impacting the performance of the composite material. Therefore, finding the optimal interface thickness is crucial to maximizing the thermal performance of the composite material.

Figure 9. Thermal conductivity of composite materials with different interface thickness.

Comparative analysis between numerical simulation and theoretical calculation

In this take a look at, we carried out theoretical calculations of the thermal conductivity in graphene-bolstered aluminum matrix composites using a mixture of DMM interface principle and hybrid policies. These effects had been then as compared with numerical simulation outcomes. As shown in Figure 10, the overall trend located in the numerical simulation consequences aligns with the theoretical predictions. Whilst the interface substances are Cu and Ag, the theoretical values are lower than the simulation outcomes. Conversely, while the interface materials are W, Mo, Cr, and Ni, the theoretical values exceed the simulation outcomes. This disparity may be attributed to the omission of thermal resistance among the matrix cloth and the interface material, as well as between the interface fabric and the graphene-bolstered section, inside the theoretical calculations. In addition, the hybridization rule employed inside the thermal conductivity theory does no longer account for the particle interactions within the strengthened segment.

Figure 10. Comparative analysis of simulated and theoretical thermal conductivity of composite material with different interface type.

In summary, whilst the theoretical calculations offer valuable insights into the thermal conductivity behavior of graphene-bolstered aluminum-based composites, certain factors, which includes thermal resistances and particle interactions, aren't fully captured by the modern technique. Destiny studies may additionally attention on refining the theoretical models to better include those considerations and beautify the accuracy of predictions.

• With the growing quantity fraction of graphene, the thermal conductivity of the composite cloth exhibits a sluggishand sizeable enhancement, with a greater magnitude of increase. Furthermore, the orientation of grapheneperforms a crucial function in figuring out the thermal conductivity of the composite fabric. While the heat flow path aligns parallel to the graphene, the thermal conductivity reaches its height. But, because the diploma of orientation increases, the thermal conductivity step by step diminishes, engaging in its lowest factor whilst the warmth drift direction is perpendicular to the graphene. Moreover, judiciously growing the particle length of graphene can effectively beautify the thermal conductivity of the composite material.

•The intrinsic thermal conductivity of the interface material performs a crucial position in determining the thermalconductivity of composite materials, especially whilst the interface thickness and the content of the reinforcingsegment are stored constant. Opting for an interface cloth with higher intrinsic thermal conductivity proves nice inimproving the general thermal conductivity of the composites.

•The thermal conductivity of composite materials is influenced by the thickness of the interface layer, primarilythrough the magnitude of the interface thermal resistance. In instances where the intrinsic thermal conductivity islow, increasing the thickness of the interface layer amplifies the interface thermal resistance, resulting in a morerapid decline in the composite material's thermal conductivity. Hence, careful selection of an appropriate interfacelayer thickness is imperative to achieve optimal thermal performance in these composites.

•The simulation results exhibit a similar trend to the theoretical values, indicating that finite element analysis-basednumerical simulations can provide valuable insights into the thermal conductivity of graphene-reinforced aluminum-based composite materials. These numerical simulations offer a valuable reference for understanding andpredicting the thermal behavior of such composites in practice.

This work was supported by Liaoning Provincial Applied Basic Research Project (2023JH2/101300233) in 2023; Basic Research Projects of Higher Education Institutions in Liaoning Province in 2023 (JYTZD20230004, JYTMS20230193).

[Crossref]

[Crossref]

[Crossref]

[Crossref]

[Crossref]

[Crossref] [Google Scholar] [PubMed]

[Crossref]