ISSN:2321-6212

ISSN:2321-6212

James Okuo1*, I Osa-Iguehide1, B Anegbe2, BM Bolanle2

1 Department of Chemistry, University of Benin, Benin, Nigeria

2 Department of Industrial Chemistry, Federal University Oye, Ekiti, Nigeria

Received: 24-Mar-2022, Manuscript No. JOMS-22-58284; Editor assigned: 26-Mar-2022, PreQC No. JOM-22-58284 (PQ); Reviewed: 09-Apr-2022, QC No. JOMS-22-58284; Revised: 11-Apr-2022, Manuscript No. JOMS-22-58284 (R); Published: 18-Apr-2022, DOI: 10.4172/2321-6212.10.4.002.

Visit for more related articles at Research & Reviews: Journal of Material Sciences

The efficient use of organic fertilizers as a source of nutrient has been a concern in the world oilpalm production. The large amount of Palm Oil Mill Sludge (POMS) and Fly Ash (FA) produced in palm oil industries can effectively be utilized as organic fertilisers and so minimize the amount of waste dispose to the environment. This study is aimed at optimizing the nutrient parameters influencing oil palm seedling growth in soil amended with FA and POMS. The nutrient parameters were optimized using Response Surface Methodology (RSM). The optimization results showed that an increase in the mass of FA and a decrease in the mass of POMS result in a decrease in the growth response of the oil palm seedlings. The responses were best with increase in the mass of POMS and a decrease in the mass of FA. Therefore, an indirect relationship exists between the masses of FA and POMS. An empirical quadratic polynomial model was developed to relate the interaction of the POMS and FA. The strong linear correlation between the observed and predicted responses showed that the model reasonably predicted the process using a quadratic polynomial. The maximum plant height of 70.4 cm at 15% soil amendment was obtained at a mass of 1.46 kg FA and 8.54 kg POMS for the 180 days planting period. Results from this study showed that co application of FA and POMS can be very effective at a maximum of 14.6% FA and minimum of 85.4% POMS by mass

Amendment; Fly ash; Oil palm seedlings; Optimization; Oil palm sludge; Stabilization; Quadratic polynomial model; Soil nutrient

Organic fertilizers are used to improve soil fertility in a productive state. Research has shown that fertilizer additions can improve the content of organic matter that is present in the soil, thereby leading to improved fertilizer efficiency [1]. In many developing countries, the utilization of inorganic fertilizer is limited due to its high purchasing cost [2,3], whereas only a small number of organic fertilizers are applied to their croplands despite the associated benefits [4, 5].

The production of oil palm in Nigeria has risen tremendously from about eight million tons in 1990 to about nine million tons in 2001 [6] and there has been a tremendous increase from 2001 till date. About 43-45% of the entire production process is in the form of waste which is either solid waste or liquid waste. The solid wastes include Empty Fruit Bunch (EFB), Palm Press Fiber (PPF), Chaff and Palm Kernel Shell (PKS) [7-10]. These solid wastes are burned as fuel in the boiler of palm oil mill at a temperature of about 450-600°C in the generation of energy for utilization in palm oil mill. Generally, after combustion, about 15% by weight of solid waste in the form of ash is produced. The ash produced is of two types which include fly ash and bottom ash.

The accumulation of these wastes is a continuous process as the production increases overtime. So there is needed to put all efforts in converting the wastes into products (such as organic fertilizer and animal feed) that will be of economic importance to the palm oil industry. Recycling and applying fly ash and sludge for agriculture purpose have many benefits. Kesh et al. [11] stated that FA serves as a repository of soil nutrients which helps to recover and improve soil properties from alkaline and saline soils. FA amended soils influence all of the soil's physical and chemical characteristics [12, 13]. Singh et al. [14] reported significant improvements in soil-based nutrient levels while Surridge et al. [15] reported the liming effect on soils which enhances the mobility of calcium or hydroxide ion, enriching the growth of bacteria. Devagi et al. [16] revealed that POMS application can lead to a significant increase of manganese, nickel and iron in water spinach, which are parallel with increasing amount of POMS.

There is high competition of the palm oil wastes for fuel and animal feeds and only small amounts of these wastes are retained in the soil. Some of these wastes constitute hazard when discharge indiscriminately into the environment. The biodegradability of these wastes makes them suitable as alternative source of amendment.

The objectives of this study are to:

Neodymium sample collection and preparation Soil samples, FA and POMS were collected from Okomu village in Ovia Southwest Local Government Area, Edo State, Nigeria. The samples were collected at a depth of 0–30 cm at about 2 km from Okomu oil palm industry. The soil samples were air dried for a period of two weeks before crushing in porcelain mortal and sieved through 2 mm sieve. The air-dried sieved soil samples were stored in air tight polythene bags and labeled prior to analysis. The fly ash was also sieved through a 2 mm sieve to obtain fine sample. The sludge sample was stabilized for a period of 100 days as described by Osa-Iguehide et al. [17]. The prepared fly ash and stabilized sludge were separately and co-applied to the soil at different rates of 2-15%.

Plant samples were analyzed according to USEPA guidelines

Physicochemical characterization: The physicochemical properties of the soil, fly ash and stabilized sludge at day 0 and 100 days were determined before and after amendment using standard methods. The pH and particle size analysis was determined by the method described by Vogel [18]. Total nitrogen and phosphorus were determined by Kjeldahl method described by Motsara et al.[19]. Flame photometric method was used for the analysis of K and Na while Mg, Ca and heavy metals were analyzed using atomic absorption spectrophotometric method described by Wuana et al. [20]. The plants biometrics was done 180 days after planting.

Nutrient parameters optimization using Response Surface Methodology (RSM)

RSM was used to assess the influence of various process parameters to maximize plant height of oil palm seedlings. The experimental design for this reaction was carried out by employing a full factorial Rotatable Central Composite Design (RCCD) for two factors with replicates at the centre point, and star points were used in the investigation by the statistical software package Design-expert® (version 8.0.6; stat-ease, Inc., Minneapolis, USA). The variables used were mass of FA(A) and mass of POMS (B) each at alpha (-1) and alpha (+1) coded levels. The actual levels of the variables for CCD experiments were selected based on the initial levels as the center points. A total of 13 experimental trials that included 4 trials for factorial design, 4 trials for axial points (two for each variable) and 5 trials for replication of the central points were performed. The response of the amendment process is plant height in Centimeter (cm). Table 1 shows the CCD experimental range of values for the process variables considered for the soil amendment process.

Statistical analysis

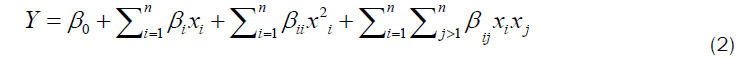

The experimental data were analyzed according to the response surface regression procedure to fit the second-order polynomial equation in which the level of significance (p-value) of all coefficients was<0.05. Based on experimental data shown in Table 1, the regression coefficient was determined by the statistical software package Design-expert® (version 8.0.6; stat-ease, Inc., Minneapolis, USA) to predict the process response as a function of independent variables and their interactions were used to understand the system behaviour. The coded values of the process parameters were determined by equation 1.

| Levels | ||||

|---|---|---|---|---|

| Independent variable | Unit | Symbol | -1 | 1 |

| Mass of FA | Kg | A | 0 | 10 |

| Mass of POMS | Kg | B | 0 | 10 |

Table 1. CCD experimental conditions for the soil amendment process.

where xi=coded value of the ith variable, Xi=uncoded value of the ith test variable and Xo=uncoded value of the ith test variable at centre point. The mathematical relationship between the process variables and response was calculated by the quadratic polynomial expression in equation 2.

where Y is the response, i.e. the plant height (cm), Xi and Xj represent the independent variables, β0 is constant, βi is linear term coefficient, βii is the quadratic term coefficient, βij is cross term coefficient and ‘n’ is the number of process variables studied and optimized during the study. ANOVA was carried out to estimate the effects of process variables and their possible interactive effects on the maximum plant height in the response surface regression procedure. The goodness and best fit of the model was evaluated by a regression coefficient R2. The response surface and contour plots were obtained using the fitted quadratic polynomial equation generated from regression analysis by keeping one of the independent variables at central value (0) and varying the other.

Pot experiments

A greenhouse pot experiment was adopted in this research. Sprouted palm seedlings obtained from Nigeria Institute for Oil Palm Research (NIFOR) were carefully sown in black cylindrical polythene bags, each containing 2 kg soil mixture (soil+FA+POMS as suggested by RSM). Prior to planting, the soil mixture was stabilized for a period of two weeks while watering once a day with respect to their water holding capacity. One sprouted palm seedling was planted per pot and each experiment was performed in triplicates. Surface irrigation was done with borehole water based on the water holding capacity of the soil (once a day) for the 180 days planting period while plant analysis was done for 60, 120 and 180 days after planting

Days before amendment Table 2 shows the physicochemical parameters of the soil, fly ash and stabilized sludge. The pH of the soil was 7.70 which is slightly above normal pH for plant growth, though most soils have pH values between 3.5 and 10 [21]. Soil pH is one of the important parameters in soil analysis as it affects most chemical processes. It specifically affects the availability of nutrients to plant by contributing significantly to the chemical forms of the different nutrients thereby affecting the chemical reactions which these nutrients undergo in soil. The fly ash was alkaline with a pH of 10.92; pH value of fly ash has close correlation with its calcium oxide content. High calcium oxide content in fly ash results in higher pH value [22]. The high pH of the FA makes it very suitable as a liming agent for acidic soil.

| pH | P(%) | N(%) | TOC (%) | TOM (%) | C:N Ratio | Na(meq/100 g) | K(meq/100 g) | Ca(meq/100 g) | Mg(meq/100 g) | |

|---|---|---|---|---|---|---|---|---|---|---|

| FA | 11 | 0 | 0 | 0.7 | 1.19 | 5.8 | 3.55 | 2 | 12.75 | 7 |

| POMS0 | 4 | 0 | 0 | 8.5 | 14.6 | 45 | 0.52 | 0 | 6.23 | 4 |

| POMS 100 | 5 | 0 | 1 | 6.6 | 11.3 | 13 | 0.59 | 0 | 7.02 | 4 |

| SOIL | 8 | 0 | 0 | 1.3 | 2.15 | 14 | 0.08 | 0 | 0.74 | 0 |

Table 2. Physicochemical parameters of the FA, POMS and soil at different stabilization.

The optimum soil pH range for most plants is between 5.5 and 7.5 [21]. This is assumed to be the normal pH range for ordinary soils that favour plant and microorganisms. However, many plants have adapted to thrive at pH values outside this range. The particle size analysis of the soil shows that, the parent soil has a clay content of 9%, silt 6% and sand 85% which makes the soil to be classified as loamy sand.

To study the individual and interactive effects of variables, a 3 point Rotated Central Composite Design (RCCD) was used for the 2 variables. The factorial point shows the values that are within the range of the coded value from the design of experiment as shown in Table 3.

| Standard order | Coded values | Actual values | |||

|---|---|---|---|---|---|

| A | B | FA (kg) | POMS (kg) | ||

| Factorial point | 1 | -1 | -1 | 1.46 | 1.46 |

| 2 | 1 | -1 | 8.54 | 1.46 | |

| 3 | -1 | 1 | 1.46 | 8.54 | |

| 4 | 1 | 1 | 8.54 | 8.54 | |

| Axial point | 5 | -1.41 | 0 | 0 | 5 |

| 6 | 1.41 | 0 | 10 | 5 | |

| 7 | 0 | -1.41 | 5 | 0 | |

| 8 | 0 | 1.41 | 5 | 10 | |

| Centre point | 9 | 0 | 0 | 5 | 5 |

| 10 | 0 | 0 | 5 | 5 | |

| 11 | 0 | 0 | 5 | 5 | |

| 12 | 0 | 0 | 5 | 5 | |

| 13 | 0 | 0 | 5 | 5 | |

Table 3. Standard order of the actual and coded values of the optimized parameters.

The axial point shows the values that are outside the range of the coded value from experimental design. The centre points show the experimental runs where the values are set halfway between the highest and lowest value. The actual values for each point show the masses of the FA and POMS that was uniformly mixed for the amendment.

Orders 1, 4, 9–13 showed the same growth pattern. The similar growth pattern showed by these orders could be attributed to the 50/50 ratio in which these orders were mixed. Order 1 had FA mass of 1.46 kg and POMS mass of 1.46 kg, order 4 had a FA mass of 8.54 kg and POMS mass of 8.54. Order 9–13 had FA mass of 5 kg and POMS mass of 5 kg. These orders were used to determine the variation in the optimization process (Table 4).

| Standard order | Response 1 (A) | Response 2 (B) | Response 3 (C) | Response 4 (D) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Days | ||||||||||||

| 60 | 120 | 180 | 60 | 120 | 180 | 60 | 120 | 180 | 60 | 120 | 180 | |

| 1. | 25.3 | 35.7 | 47.9 | 32.1 | 41.2 | 52.1 | 23.8 | 40.8 | 54.2 | 24.2 | 37.2 | 46.5 |

| 2. | 22.8 | 29.6 | 42.8 | 21.6 | 27.4 | 32.6 | 19.5 | 24.1 | 26.5 | 16.4 | 19.3 | 23.2 |

| 3. | 28.9 | 42.4 | 57.8 | 37.6 | 51.3 | 61.3 | 29.7 | 58.1 | 64.7 | 27.1 | 58.4 | 70.4 |

| 4. | 24.8 | 36.3 | 44.2 | 30.7 | 39.8 | 53.6 | 25.9 | 41.4 | 56.6 | 23.1 | 35.2 | 49.8 |

| 5. | 29.5 | 47.5 | 57.3 | 38.4 | 52.8 | 59.8 | 28.5 | 54.4 | 63.6 | 25.9 | 56.8 | 69.8 |

| 6. | 23.9 | 32.6 | 43.2 | 26.8 | 32.7 | 44.7 | 20.1 | 30.9 | 42.1 | 19.7 | 25.4 | 33.9 |

| 7. | 22.4 | 29.4 | 35.7 | 19.2 | 21 | 27.6 | 15.6 | 18.5 | 22.1 | 11.3 | 14.7 | 19.8 |

| 8. | 27.1 | 38.3 | 51.7 | 35.7 | 44.4 | 55.8 | 30.7 | 44.2 | 57.3 | 26.3 | 49.9 | 60.9 |

| 9. | 25.1 | 34.7 | 46.2 | 31.4 | 40.1 | 50.7 | 23.7 | 41.4 | 53.2 | 24.2 | 35.2 | 47.6 |

| 10. | 26.2 | 36.3 | 44.9 | 33.4 | 39.8 | 51.5 | 24.9 | 38.5 | 52.9 | 23.5 | 36.8 | 46.2 |

| 11. | 25.8 | 33.9 | 48.4 | 32.6 | 40.8 | 51.9 | 24.2 | 39.7 | 54.5 | 23.9 | 37.4 | 45.7 |

| 12. | 24.6 | 37.6 | 45.6 | 33.3 | 41.3 | 52 | 25.2 | 38.1 | 53.3 | 24.8 | 35.2 | 48.9 |

| 13. | 25.7 | 36.5 | 46.9 | 30.9 | 39.8 | 50.8 | 23.9 | 37.7 | 53.9 | 23.8 | 35.8 | 47.1 |

Response A = 2 % Amendment, Response B = 5 % Amendment, Response C = 10 % Amendment, Response D =15 % Amendment

Table 4. Growth Analysis of Oil Palm Seedlings (cm).

Generally there were increases in plant heights for all the orders (orders 1-15) with 2–5% amendments as a result decomposition of the organic matter at low pH making nutrients available for plant uptake. Thereafter, the plant heights decreased with 10–15% amendments for the 180 days planting period.

This growth pattern can be attributed to the fact that the FA was more dominant in affecting the plant height due to the slight increase in the pH of these orders as the rate of amendment increases. The decrease in plant heights at 15% might be due to high pH. Higher pH prevents nutrient availability for the plant uptake. The high pH led to the low availability of the nutrient as observed in the nutrient analysis of the plant (Tables 5-7). Study has shown that there is restriction in plant growth in strongly alkaline condition (pH 8.5-9) [23] due to poor aeration, depletion of plant-available water leading to the soils becoming hard and cloddy. There was also a gradual decrease in concentration of nitrogen and phosphorus as the rate of amendment increased with orders 2 and 7(Tables 5-7).

| Standard order | Parameters | 2% | 5% | 10% | 15% |

|---|---|---|---|---|---|

| 2 | N | 0.151 | 0.143 | 0.132 | 0.12 |

| P | 0.092 | 0.086 | 0.081 | 0.058 | |

| K | 0.038 | 0.044 | 0.048 | 0.057 | |

| 3 | N | 0.198 | 0.217 | 0.208 | 0.193 |

| P | 0.118 | 0.122 | 0.129 | 0.132 | |

| K | 0.008 | 0.013 | 0.021 | 0.026 | |

| 5 | N | 0.203 | 0.219 | 0.196 | 0.186 |

| P | 0.132 | 0.139 | 0.135 | 0.128 | |

| K | 0.005 | 0.012 | 0.018 | 0.023 | |

| 7 | N | 0.117 | 0.101 | 0.092 | 0.077 |

| P | 0.086 | 0.081 | 0.075 | 0.068 | |

| K | 0.041 | 0.049 | 0.056 | 0.072 |

Table 5. Nutrient analysis (%) of plant 60 days after planting.

| Standard order | Parameters | 2% | 5% | 10% | 15% |

|---|---|---|---|---|---|

| 2 | N | 0.169 | 0.161 | 0.155 | 0.127 |

| P | 0.103 | 0.095 | 0.087 | 0.066 | |

| K | 0.046 | 0.056 | 0.064 | 0.069 | |

| 3 | N | 0.221 | 0.239 | 0.251 | 0.249 |

| P | 0.138 | 0.153 | 0.178 | 0.182 | |

| K | 0.012 | 0.019 | 0.026 | 0.032 | |

| 5 | N | 0.224 | 0.246 | 0.253 | 0.259 |

| P | 0.142 | 0.157 | 0.171 | 0.179 | |

| K | 0.009 | 0.014 | 0.022 | 0.034 | |

| 7 | N | 0.152 | 0.121 | 0.115 | 0.087 |

| P | 0.107 | 0.096 | 0.093 | 0.081 | |

| K | 0.054 | 0.061 | 0.068 | 0.113 | |

| K | 0.025 | 0.034 | 0.041 | 0.048 |

Table 6. Nutrient analysis (%) of plant 120 days after planting.

| Standard order | Parameters | 2% | 5% | 10% | 15% |

|---|---|---|---|---|---|

| 2 | N | 0.185 | 0.172 | 0.145 | 0.129 |

| P | 0.122 | 0.106 | 0.093 | 0.067 | |

| K | 0.073 | 0.089 | 0.098 | 0.106 | |

| 3 | N | 0.258 | 0.279 | 0.303 | 0.316 |

| P | 0.196 | 0.217 | 0.234 | 0.257 | |

| K | 0.021 | 0.028 | 0.032 | 0.041 | |

| 5 | N | 0.249 | 0.262 | 0.294 | 0.307 |

| P | 0.185 | 0.189 | 0.225 | 0.233 | |

| K | 0.015 | 0.024 | 0.029 | 0.037 | |

| 7 | N | 0.169 | 0.134 | 0.128 | 0.094 |

| P | 0.134 | 0.112 | 0.104 | 0.081 | |

| K | 0.087 | 0.098 | 0.105 | 0.113 |

Table 7. Nutrient analysis (%) of plant 180 days after planting.

In this paper orders 3 and 5 gave the best results with FA and POMS percentage amendments, while orders 2 and 7 gave the least (Table 4). Orders 2 and 7 showed similar growth pattern. Order 2 has FA mass of 8.54 kg (85.40%) and POMS mass of 1.46 kg (14.60%); order 7 has FA mass of 5 kg (100.00%) and a POMS mass of 0 kg (0.00%) with plant heights of 23.2 and 19.8 cm respectively at 15% amendment. Orders 3 and 5 also showed similar growth pattern. The optimum OPS height of 70.4 cm was observed with FA mass of 1.46 kg (14.60%) and POMS mass of 8.54 kg (85.40%) at 15% amendment for order 3, while order 5 has optimum OPS height of 69.8 cm with FA mass of 0.00 kg (0.00%) and POMS mass of 5.00 kg (100.00%) at the same level of amendment.

Figure 1(A-D) showed the predicted and actual heights for 2-15% soil amendment. The strong linear correlation between the predicted and the actual OPS height indicates that there is close agreement between the observed and the predicted plant heights. This indicates that the model is satisfactory. Tables 8-11 showed model summary statistics for the OPS heights.

| Source | Standard.Dev. | R-squared | Adjusted R-squared | Predicted R-squared | Press | |

|---|---|---|---|---|---|---|

| Linear | 3.2079 | 0.7696 | 0.7235 | 0.5156 | 216.3493 | |

| 2FI | 3.1074 | 0.8054 | 0.7406 | 0.4995 | 223.5534 | |

| Quadratic | 1.985 | 0.9382 | 0.8941 | 0.6501 | 156.2881 | Suggested |

| Cubic | 1.2721 | 0.9819 | 0.9565 | 0.8443 | 69.5387 | Aliased |

Table 8. Model summary statistics for plant height (A).

| Source | Standard.Dev. | R-squared | Adjusted R-squared | Predicted R-squared | Press | |

|---|---|---|---|---|---|---|

| Linear | 4.8202 | 0.7892 | 0.7470 | 0.5523 | 493.3704 | |

| 2FI | 4.5135 | 0.8336 | 0.7782 | 0.6226 | 415.8845 | |

| Quadratic | 1.9785 | 0.9751 | 0.9574 | 0.8306 | 186.7175 | Suggested |

| Cubic | 1.3761 | 0.9914 | 0.9794 | 0.5333 | 514.2938 | Aliased |

Table 9. Model summary statistics for plant height (B).

There is a positive significant correlation between the adjusted R-squared values (0.8941, 0.9574, 0.9552 and 0.9855) and the predicted R-squared values (0.650, 0.8306, 0.8188 and 0.9527) for amendment A, B, C and D respectively (Tables 8-11). The high R-squared values show that the model (Equations 3-6) reasonably predicted the process using a quadratic polynomial. The data obtained were subjected to Analysis Of Variance (ANOVA) at a significant level of 5%. The high F-values of 21.2712, 54.9042, 52.1956 and 164.6641 and the very low P-values range of<0.0001–0.0004 obtained for amendments A, B, C and D respectively indicated a very significant model. The coefficient of regression (R2) was used to validate the fitness of the model equations. High R2 values of 0.9382, 0.9751, 0.9739 and 0.9916 obtained for soil amendments A, B, C and D showed that more than 90% of the variability in the OPS heights in the soil amendment process can be explained by the model.

| Source | Standard.Dev. | R-squared | Adjusted R-squared | Predicted R-squared | Press | |

|---|---|---|---|---|---|---|

| Linear | 6.3466 | 0.7957 | 0.7549 | 0.5765 | 835.0420 | |

| 2FI | 5.8381 | 0.8444 | 0.7926 | 0.6718 | 647.2002 | |

| Quadratic | 2.7125 | 0.9739 | 0.9552 | 0.8188 | 357.2059 | Suggested |

| Cubic | 2.7325 | 0.9811 | 0.9546 | -0.1601 | 2287.4300 | Aliased |

Table 10. Model summary statistics for plant height (C).

| Source | Standard.Dev. | R-squared | Adjusted R-squared | Predicted R-squared | Press | |

|---|---|---|---|---|---|---|

| Linear | 3.9696 | 0.9428 | 0.9313 | 0.8761 | 341.1721 | |

| 2FI | 4.1601 | 0.9434 | 0.9246 | 0.8679 | 363.7466 | |

| Quadratic | 1.8208 | 0.9916 | 0.9855 | 0.9527 | 130.2956 | Suggested |

| Cubic | 1.4171 | 0.9964 | 0.9912 | 0.9085 | 251.7813 | Aliased |

Table 11. Model summary statistics of plant height (D).

Coefficient of Variation (CV) in all cases (<5.5%) ranged 3.53–5.38% and is within acceptable range. The small values of CV give better reproducibility. Adequate precision measures the signal to noise ratio. A ratio greater than 4 is desirable. The ratio of 15.43, 24.00, 23.20 and 41.09 obtained for the soil amendments indicate an adequate signal [24]. It also shows that the model can be used to navigate the design space.

Model deduction

Equations (3-6) give the empirical model of the process, showing the relationship between plant height and the variables considered (mass of FA and POMS) in coded symbols.

PHA=46.40-5.05A+4.18B-2.00AB+2.49A2-1.18B2 (3)

PHB=51.38-6.06A+8.49B+3.50AB+1.31A2-4.34B2 (4)

PHC=53.56-8.28A+11.30B+4.90AB+0.70A2-5.87B2 (5)

PHD=47.10-11.83A+13.58B+0.67AB+2.72A2-3.03B2 (6)

In equations (3-6) a positive coefficient means that an increase in the variable will cause an increase in the response while a negative coefficient will result in a decrease in the response [24, 25].

Fly ash mass (A) has the highest effect (coefficient of 5.05) on the OPS height at 2% soil amendment. Equations 4–6 indicate that the POMS mass (B) has the greatest effect on the OPS height. An increase in the mass of POMS led to a corresponding increase in the plant height.

It was observed from Figures 2-5 that the mass of POMS showed more dominant effect on the plant height than the mass of fly ash. The maximum OPS height of 70.97 cm was observed at a POMS mass of 8.53 kg and fly ash mass of 1.58 kg for 15%.

This research attempted to assess the effect of optimizing nutrient parameters on the growth of oil palm seedlings in soil amended with Fly Ash (FA) and Palm Oil Mill Sludge (POMS). The optimization of results using RSM showed that an increase in the mass of FA and a decrease in the mass of POMS resulted in a decrease in the growth response of the oil palm seedlings and vice versa. The result obtained from the developed empirical quadratic polynomial model showed that strong linear correlation existed between the observed plant responses and predicted responses and thus the model reasonably predicted the process using a quadratic polynomial. The maximum plant height of 70.4 cm at 15% soil amendment was obtained at a mass of 1.46 kg FA and 8.54 kg POMS for the 180 days planting period. The co-application of FA and POMS can be very effective at a maximum of 14.6% FA and minimum of 85.4% POMS by mass for planting oil palm seedlings.

We are most grateful to the Department of Chemistry University of Benin for providing an enabling environment for the research work.

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.