e-ISSN: 2320-0812

e-ISSN: 2320-0812

1Department of Biochemistry, Kebbi State University of Science and Technology, P.M.B. 1144, Aliero, Nigeria.

2Environmental Mgt. Unit, Kebbi State University of Science and Technology, P.M.B. 1144, Aliero, Nigeria.

Received Date: 13/11/2013; Accepted Date: 26/12/2013; Published Date: 30/12/2013

Visit for more related articles at Research & Reviews: Journal of Pharmaceutical Analysis

Hexane extracts of shea nut fat were subjected to physico-chemical analysis which revealed the following results; Saponification values mgKOH/g 141.65 0.40c, 166.1 0.80ab and 169.79 1.29a, Iodine values I2/100g 51.17 0.18c, 53.54 0.39a and 51.78 0.26b, Acid values mgKOH/g 15.52 1.62a , 14.26 0.33b and 7.52 0.33bc, Free fatty acids mg/g 5.04 0.05b, 4.20 0.04bc and 7.52 0.33a , Specific gravities 0.94 0.02a, 0.96 0.03a and 0.93 0.01a for Illo, Kwanga and Kwere samples respectivel. The statistical package used was the Analysis of Variance using ANOVA. The same subscript indicates that there is no significant difference while different subscript letters indicates that there is significant difference between the means. The physico-chemical characteristics of the various fat extracts justified their relevance for soap making and other cosmetic preparations.

shea nut, fat, extracts, physic-chemical

Shea butter is the fat content of the kernel of shea nut (Vitellaria paradoxa) which grows naturally from the wild and uncultivated state in most parts of Africa. The fat is used as edible oil and for raw material in the production of soaps, pomade, drugs and medicinal ointments [1]. Vitellaria paradoxa tree starts flowering in early November, with picking or gathering of fruits lasting from April to August every year. When the shea fruits ripen, they fall under their own weight to the ground and are gathered by hand. The fruit is green in color, has a fleshy edible pulp which contains protein and carbohydrates, and is very sweet [2]. The nuts sold on the International market are harvested from village tree populations in several West African countries. The fat content of the kernel and fatty acid profile are, however, extremely variable across this zone [3]. The fat obtained from the shea kernel is the most valued product from the shea tree [4]. Shea oil extracted from the seed kernels is the main source of fat for preparation of sauce, frying and baking in addition to being a cosmetic and traditional medicine in many rural areas [5].

Although shea butter is important in food, cosmetic and pharmaceutical industry, variations between physico-chemical compositions and fatty acid profile have been reported in different countries [6,7]. Such variations in physico-chemical compositions have been attributed to environmental factors such as climate, temperature, soil fertility; maturation period; agronomic practices and genetic substitution. Besides, it has also been suggested that post harvest handling practices such as fruit harvesting, seed drying, storage and oil extraction processes may cause variation in physico-chemical characteristics of shea butter . The fruit pulp and oil from the shea nuts have been reported to be vital for supporting the livelihoods of the parklands communities [4,8,3]. It was with these views in mind that this study assessed the physico-chemical characteristics of shea butter (V. paradoxa) in some selected areas of Kebbi State, Nigeria.

Collection of sample

Selected samples of Vitellaria paradoxa seeds were obtained from the market of Kwanga town (Ngaski Local Government), Kwere town (Zuru Local Government) and Illo town (Bagudo Local Government). Nigeria. It was identified and authenticated by Dr. Dhramemdra Singh of the Botany unit Biological Sciences Department, Kebbi State University of Science and Technology Aleiro. Confirmation of taxonomic identity of the shea nut leaves and stems (voucher No. 320) was achieved by comparing them with the specimens kept in the Herbarium of Department of Biological Sciences. The dried shelled kernels were deshelled using stone, after which the dried shea nut kernels were crushed into powder using mortar and pestle and was stored in a plastic container for oil extraction. All chemicals and reagents used were of analytical grade. In all cases, distilled water was used in the preparation of solutions and dilution unless otherwise stated.

The extraction of oil from the tubers was carried out in a soxhlet apparatus using analytical grade hexane (n- hexane) as refluxing or extracting solvent for the work. At the completion of the extraction process the oil was recovered from the mixture by evaporating the residual extracting solvent in an oven set at 50°C for 1h and stored in the bottle. This process was repeated until a substantial quantity of oil was achieved. Each batch of extraction lasted for about 5 hours on the average [9].

Determination of Percentage Yield.

The oil obtained from the extraction was transferred into a measuring cylinder which was placed over water bath for 30 min at 70Ãâ¹ÃÅ¡C so as to ensure complete evaporation of solvent and volume of the oil was recorded.

Determination of Colour

The colour of the oil samples was determined by observation using several independent competent individuals. Oil colour was correlated using colour charts [9].

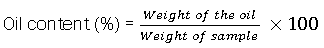

Determination of Percentage Yield

The hexane extract of the shea nut fat was transferred into a measuring cylinder which was placed over water bath for 30 min at 70Ãâ¹ÃÅ¡C so as to ensure complete evaporation of solvent, and percentage yield was calculated as follow.

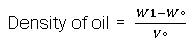

Determination of Specific Density

This was performed according to literature report [10]. The 10ml of the oil was measured in a pre-weighed measuring cylinder. The weight of the cylinder and oil was measured; the weight of the oil was then obtained by subtracting the weight of the cylinder from the weight of the oil and cylinder. The specific density of the oil was obtained using equation below.

Where W1 = weight of empty measuring cylinder + oil. Wo = weight of measuring cylinder, Vo = volume of oil used.

Determination of Saponification Value, Acid Value, Iodine Value and Free Fatty Acid.

These were performed according to standard methods of analysis [11].

Values are in mean ±standard deviation of triplicate determinations. The same subscript indicates that there is no significant difference while different subscript letters indicates that there is significant difference between the means .

The physicochemical analysis (Table 1), determined for the soxhlet extracted indigenous Shea nut seed oil from three different local governments (Illo, Kwanga and Kwere). At room temperature (290C) all seed oil are liquids. All the seed oils are pale to dark yellow colour. Saponification value for Illo fat extract was 141 ± 0.4 mgKOH/g the value obtained was lower than that of Dennettia tripatala fruit oil(Pepper fruit)159.33±1-20 suitable for soap making [12] but higher than that of beeswax (93 mg KOH/g), which are commonly used in soap making [13]. This indicates that the fat could be used in soap making. Kwanga fat extract was found to have 166.1 0.80 mg KOH/g and that of K were was 169.79 1.29 mg KOH/g which were lower than 213mg KOH/g of neem seed oil (Akpan.1999) and 253.2mgKOH/g of Coconut oil [12] higher than that of Dennettia tripatala fruit oil (Pepper fruit) 159.33±1-20 [14] and African pear oil 143.76 mg KOH/g which could be good for soap making [15]. This indicates that the fat could also be used in soap making since it saponification value falls within the range of these oils. Higher saponification justifies the usage of fat or oil for soap production. Iodine value for Illo fat extract was 51.17 0.18, 53.54 for Kwanga and 51.78 0.26 for Kwere (All less than 100) were obtained, which shows that the oil belongs to the class of Non-drying oils, which are useful in the manufacture of soaps [16]. Acid value for Illo fat extract was 15.52 1.62 mg KOH/g and14.26 0.33 mg KOH/g for Kwanga were obtained which were lower than that of olive oil 17 mgKOH/g [17] higher than the 10.49 3mgKOH/g reported [18] suitable for soap production, while Kwere fat extract 7.52 0.33mg KOH/g was obtained which is lower than 15.52 1.62 mg KOH/g and14.26 0.33 mg KOH/g obtained for Illo and Kwanga fat extract respectively; higher than that of Palm kernel seed oil 0.834±0.004mgKOH/g reported [19] suitable for soap production. Free fatty acid for Illo fat extract was 5.04 0.05 which had almost the same value with that for rubber seed oil of 5.20% [20] but greater than that of Kwanga fat extract 4.2 0.04 and lower than that of Kwere fat extract 7.52 0.33. The free fatty acids of the three fat extracts were higher than the values for bread-fruit oil (2.86%) and breadnut oil, 1.89% [14]. Oil with highly acidic free fatty acid indicates unsuitability for edible purpose except for technical purposes [21]. The specific gravity of the fat extracts ranges between 0.94 0.02 for Illo sample to 0.96 0.03 for Kwanga sample and 0.93 0.01 for Kwere sample. The values compare with 0.82 and 0.84 reported for the pulp and seed of Dacryodes edulis seed respectively [22]. None of the seed oil had offensive odour.

The physico-chemical characteristics of the various fat extracts exploited in this research considerably favours utilization for soap making and other cosmetic preparations.

The authors wish to acknowledge the contribution of Mujtaba Augie, a Technologist in the Department of Biochemistry, KSUST, Aliero, Nigeria and TetFund Board of Trustees, Nigeria, for awarding the TetFund Grant to carry out this research work.