ISSN:2321-6212

ISSN:2321-6212

Shilpa Kasargod Nagaraj1, Sachhidananda Shivanna1, Nithin Kundachira Subramani1,2* and Hatna Siddaramaiah1

1Department of Polymer Science and Technology, Sri Jayachamarajendra College of Engineering, Mysuru, India

2Department of Chemistry, The National Institute of Engineering, Mysuru, India

Received Date: October 03, 2016; Accepted Date: October 03, 2016; Published Date: October 10, 2016

DOI: 10.4172/2321-6212.1000158

Visit for more related articles at Research & Reviews: Journal of Material Sciences

Polymers and their hybrid composites are of significant interest to material scientists, owing to fascinating end product applications. The ever increasing demand for polymer based composite systems has imposed the scientific community to design, develop and characterize novel hybrid composites for advanced material applications. Thus, advanced characterization tools are in great demand for material research. Powder X-Ray Diffraction (P-XRD) is one such characterization tool that offers the advantage of simultaneously characterizing both the precursor and end products with a detailed qualitative presentation of their micro-structural behaviours. Herein, we revisit P-XRD as a powerful tool to characterize polymers and their composite films with appropriate literature evidence.

P-XRD; Crystallite phase; Degree of crystallinity

Polymer nanocomposites are a new class of multifunctional hybrids that are essentially physical mixtures of nanostructured fillers materials embedded in a polymer host. The unique initiative of reinforcing nanostructured additive phase is to enable the extraction of multifunctional behaviors that are essentially a product of synergistic interactions between the constituents systems. However, in recent decades Polymer Inorganic Nanocomposites (PINCs) have attracted significant research interest as advanced multifunctional materials for future opto-electronic devices [1]. Generally, PINCs display unique physico-chemical and physico-mechanical behaviors that are quite different from their individual components. In addition to the properties of indivual components, the polymer-filler interface also plays a crucial role in determining the absolute properties of the composite systems [2]. In addition, the size of the fillers and their inherent material properties are also of specific interest in the design of multifunctional polymer based nanocomposite systems [3,4]. Polymer nanocomposites with ultrafine dimensions and high aspect ratios are known to offer improved material behaviors in contrast to their micro composite analogues. As the filler dimension reach nanometric scale, there occurs a dramatic improvement in the interfacial interactions and hence advanced material performance. Most of the early and some of the recent research efforts are focused on visualizing the extent of interfacial interactions between the organic polymer and the inorganic host that affects maximum property enhancement [5]. The addition of only a few weight percent of inorganic fillers has been observed to have profound impact on the material outcome. The origin of nanocomposite technology has revolutionized the world of engineering polymers with numerous end applications. Polymer based Au nanocomposite was probably the first reported PINC [6-8], which were then addressed as hybrids/molecular composites Nevertheless, it was only in 1990, the word nanocomposite was globalized, when motor vehicle fabricated using polymer-clay hybrids were hit the roads. Ever since, there have been consistent efforts to develop high flexible advanced functional materials by introducing various inorganic fillers into varying polymer matrices. In recent years, the rapidly evolving science of nanostructured materials and more readily available state of art characterization techniques has opened up the technological gateway towards the design and development of novel multi component systems with improved magnetic, catalytic, electrochemical, electrical, and biomedical performance [9,10]. The most frequently studied filler materials include metals such as Au, Ag, Cu, Ge, Pt, Fe and Co, metallic ceramics such as ZnO, CeO2, TiO2, SiO2, semiconductors such as PbS, CdS, CdSe, CdTe and so forth. While, the choice of the polymeric matrix (industrial plastics and/or conducting polymers and/or transparent polymers) is dependent on the end applications, such as cesium zincate reinforced poly(vinyl alcohol) that offers filler dependent photonic emission [11], calcium zincate reinforced Poly (vinyl alcohol) that presents excellent UV shielding in conjunction with high flexibility and visible transparency [12,13],CdS reinforced PMMA that presents novel photoluminescent behaviors and so forth. Further, the fascinating real time outdoor applications and acknowledged versatility of PINCs arises from the structural reorganizations of multi component systems. Powder X-ray Diffraction (P-XRD) has been long established as an useful toll to characterize the gross structural behaviors of crystalline/semi crystalline polymer based nanocomposites. Herein, we revisit P-XRD technique as an effective tool to establish the molecular structure of polymeric systems, with special emphasis on inorganic nano filler reinforced nanocomposite systems [10,11].

Powder X-ray diffractometer

P-XRD technique utilizes the X-ray scattering phenomenon to elucidate the crystal structure of crystalline/semicrystalline materials, with scattering of X-rays by periodic array of atoms giving rise to definite diffraction patterns that bestows a qualitative image of atomic arrangements within the crystal lattice. P-XRD is the most sought after and convenient technique towards the characterization of polymer based nanocomposite in contrast to single crystal technique, which demands the sample is the form of indivual/single/independent crystals. Furthermore, XRD is an versatile, non-destructive characterization technique that offers a thorough output of chemical composition and hence the crystallographic structure of materials [14-16].

Applications of P-XRD technique to characterize polymer based nanocomposite films

P-XRD is an useful tool to differentiate the polymeric systems, based on the nature of crystalline phases (crystalline/ microcrystalline/amorphous). It also serves as a fingerprint for polymer identification in addition to offering a qualitative measure of degree of crystallinity. Polymeric systems usually solidify in various crystalline states, however, majority of them are usually mixtures of crystalline/amorphous states. In scientific terms, even highly crystalline materials are known to offer a certain degree of crystallinity [17]. The P-XRD profiles (Figure 1) of highly crystalline system presents sharp and well defined diffraction peaks (Figure 1c), while microcrystalline polymers exhibit relatively broader peaks (Figure 1b) due to smaller crystallites; however microcrystalline polymers can be assigned a definite crystal structure, while amorphous polymers are those that present a very broad (Figure 1a) X-ray diffractograms that are hard to be defined by any crystalline models.

Characterizing the crystalline phases of polymers/polymer based composites

the polymer under study is crystalline, then the P-XRD profiles present definite crystalline patterns with coherent scattering in line with the Bragg’s law;

nλ=2dhkl sin θ (1)

Where, θ is the glancing angle is a non-zero whole number that defines the order of diffraction, while dhkl is the interplanar spacing of the particular crystal phase [18].

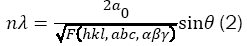

Nevertheless, all other lattice parameters may be determined by the relation;

Where, a, b and c are the unit lengths in x y z directions, α, β & γ are axial angles while, h, k and l are the Miller indices [19]. The position and relative intensities serve as fingerprint of polymer crystalline phases, thereby giving a complete qualitative overview of polymer crystal structure. Furthermore, the XRD patterns of can also be employed to characterize the nature of interaction between two or more polymeric composites. The XRD patterns of polymers are found to be additive with mixture of two immiscible (crystalline polyethylene and snon-crystalline poly (isobutene)) (Figure 2) showing contributions from both the polymers. However, if blending occurs at the atomic levels, an entirely new diffraction pattern would arise from the novel atomic arrangement. This additive phenomenon is being well exploited in polymer based nanocomposite research, wherein the occurrence of nano filler contributed diffraction patterns in the composite X-ray profile substantiates the presence of filler materials in the polymeric host and hence a successful composite preparation. Numerous researchers have substantiated successful composite development through XRD studies, with Nithin et al. substantiating the presence of cesium zincate [12] in PVA matrix (Figure 3), while Singh et al. have successful developed cuprous oxide reinforced chitosan composites for bio sensing applications [20].

Determination of degree of crystallinity in polymers/polymer based composites

The degree of crystallinity offered by polymers and their composite films is found to have profound impact on their end applications [21,22], which have imposed the scientific community to look out for novel characterization tools to characterize the extent of polymer crystallinity and P-XRD is one such unique tool that quantitates the crystallinity of polymers. The determination of polymer crystallinity makes use of an empirical two-phase model that visualizes the polymer/composite under study to be made exclusively of crystalline and amorphous phases, with no regions of semicrystalline organization. The determination of degree of crystallinity demands the separation of diffractograms into crystalline and amorphous peaks using 100% crystalline and amorphous references [23] and the International Centre for Diffraction Data (ICDD), an authentic database offers a number of commercial polymers with well-defined diffraction patterns. The degree of crystallinity of polymer based systems is determined using the relation;

χc=[Ic/(Ia+ Ic)]×100% (3)

Where, Ic and Ia are diffraction intensities of crystalline and amorphous phases respectively.

Micro structural analysis and Determination of Crystallite size in polymers/polymer based composites

P-XRD technique is also employed to determine the crystallite dimensions using the half-width of highly intense diffraction peaks, with large half-width corresponding to smaller crystallites, and narrow half-width corresponding to large crystallites. The broadening of the diffraction peaks may be due to lattice distortions and/or structural defects [24]. The crystallite size is however determined using the Scherrer’s Equation;

Lhkl=Kλ/βcosθ (4)

Where, Lhkl is the crystallite dimension, b is the half-width of highest intensity peak, K is a constant, while is the wavelength of X-ray.

Although rapidly advancing field of technology has revolutionized P-XRD technique as an advanced tool towards the micro structural characterization of polymers and their composite systems, yet they suffer from sensitivity issues, when analyzed for multi-component hybrids and demands a controlled diffraction pattern. Thus, advanced simulation techniques are the need of the hour to further improvise P-XRD as a powerful Tool to characterize polymers and their composite films.