e-ISSN: 2320-0812

e-ISSN: 2320-0812

Munshi Mahammed Tanzil Mahammed Aslam1*, Saisivam Srinivasan1, Rabadiya Vibhuti Amitkumar1, Shailendra K. Mehta2

1 Department of Pharmacy, N. R. Vekaria Institute of Pharmacy, Gujarat Technological University, Junagadh, Gujarat, India

2 ICPA Healthcare Products Ltd. Ankleshwar, Gujarat, India

Received: 11-Feb-2022, Manuscript No. JPA-22-53967; Editor assigned: 14-Feb-2022, PreQC No. JPA-22-53967(PQ); Reviewed: 25-Feb-2022, QC No. JPA-22-53967; Revised: 28-Feb-2022, Manuscript No. JPA-22-53967(R); Published: 07-Mar-2022, DOI:10.4172/2320-0812.11.02.002

Visit for more related articles at Research & Reviews: Journal of Pharmaceutical Analysis

A simple, rapid, accurate, precise and robust Gas Chromatographic (GC) method has been developed for the simultaneous estimation of Menthol, Camphor and Methyl Salicylate from an anti-arthritic spray. The separation of these three constituents was performed on DB-23 column (60 m × 250 µm × 0.25 µm). The Nitrogen was used as carrier gas at a flow rate of 2.5 mL/min. The inlet temperature and detector temperature were set as 250°C and 280°C respectively. The initial oven temperatures was 125°C for 5 min, then increase to 150°C at the ramp of 3°C/min and finally reach to 200°C at the ramp of 10°C/min. The ALS (Automatic Liquid Sampler) system was used for sample injection. The injection volume was 2 µl. The run time of chromatogram was 20.333 min. The proposed GC method provides a good resolution of Menthol, Camphor and Methyl Salicylate. The method was validated as per ICH guidelines. The linearity of Menthol, Camphor and Methyl Salicylate were found to be in the range of 10-50 µg/mL, 20-60 µg/mL and 100-300 µg/mL respectively. The recovery was calculated by using external standard method and the mean average recovery for Menthol, Camphor and Methyl Salicylate were found to be 100.55%, 99.93% and 99.95%. The tested validation parameters were found to be within acceptable limits. The method was successfully applied for quantification of these three ingredients in anti-arthritic spray formulation.

Gas chromatography; Active ingredients; Automatic liquid sampler; Anti-arthritic spray; Inflammation

Menthol, Camphor and Methyl Salicylate are the active ingredients of many topical formulations used for the treatment of rheumatic diseases. These are common ingredients used in certain topical preparation due to their analgesic and anti-inflammatory activity [1] (Figure 1).

Since time immemorial, various herbs and their derived compounds have been used in treatment of inflammation. Inflammation is a normal, protective response to tissue injury caused by physical trauma, noxious chemicals or microbiologic agents, which is a part of the host defense. Sometimes, inflammation seems to produce events that are quite serious and become chronic like occurrence of rheumatoid arthritis and hay fever which may be life threatening. Rubor (redness), calor (heat), tumor (swelling) and dolor (pain) are the main signs of inflammation [2].

S. P. Sethy has found from his review that GC with capillary column can be suitable for simultaneous identification and detection of active substance as well as purity evaluation in the presence of matrix constituents. Thus such an injection method increase the stability of the injected sample, thus also decreasing the number of peaks in the chromatogram Therefore an attempt has been made to establish conditions for identification and determination active constituents in the presence of a base constituents, while considering the effect on the results obtained from an gel containing menthol and methyl salicylate by using capillary gas chromatography [3].

Because of the volatility of these constituents, it is not surprising that these compounds are generally determined with GC. Few reports can be found about the determination of these constituents in pharmaceutical products [4].

A recent trip to a community pharmacy revealed 35 different ingredients. Of those products, 16 contained only menthol in amount ranging from 1.27% to 16%. One spray product listed menthol as the only active ingredients but no content was given. Two products contained menthol and camphor only, but neither listed content for camphor and only one product listed menthol at 2.5%. Fourteen products contained menthol and 30% methyl salicylate. One of the store brand product contained menthol and methyl salicylate as active ingredients in unlisted amounts. Three products contained all the ingredients, with the most concentrated product containing 30% methyl salicylate, 10% menthol and 4% camphor. These products are manufactured and sold in a variety of forms including: creams, gels, balms, rub-on-sticks, patches, pain reliever mousses etc [5].

Assay methods for the quantitative determination of combinations of any two of these drugs have been reported. These methods were based on Gas-Liquid Chromatography (GLC) since these drugs are volatile substances. However, only a few methods were published which allowed the assay of mixtures containing all three drugs [6].

Since many pharmaceutical preparations contain camphor and menthol, it is desirable to use a method which is both fast and accurate for the simultaneous determination of camphor and menthol [7].

In this paper, we have reported a gas chromatographic method for simultaneous estimation of these three constituents from anti-arthritic spray which contains Menthol, Camphor and Methyl Salicylate 3.0%, 4.0% and 20% respectively. The literature review reveals that till now, no any published method is reported for estimation of these three constituents from anti-arthritic spray which is research product yet to be commercialized. To confirm suitability of developed method for routine analysis, method was validated as per the ICH guidelines [8].This method can be successfully applied for routine quality control analysis.

The method was developed on GC of Agilent Technologies equipped with FID (Flame Ionization Detector) in 2017-18 at ICPA healthcare products ltd. Ankleshwar by using following parameters.

Chromatographic parameters

• Column: DB-23 (60 m × 250 μm × 0.25 μm)

• Oven temperature: 125°C(5 min), increase to 150°C (ramp 3°C/min), reach to 200°C (ramp 10°C/min)

• Time of run: 20.333 min

• Inlet temperature: 250°C

• Detector temperature: 280°C

• Mode: Split

• Split ratio: 20:

• Injection volume: 2 μl

• Carrier gas: Nitrogen

• Flow rate: 2.5 mL/min

• H2 flow: 30 mL/min

• Air flow: 300 mL/min

• N2 makeup flow: 25 mL/min

Reagents and materials

The following reagents and materials were used: Menthol of Hindustan Mint and Agro Products Pct. Ltd., Camphor of Camphor and Allied Product, Methyl salicylate of John Aromas and Methanol of Merck (all ingredients available at ICPA healthcare product ltd. Ankleshwar, Gujarat, India).

Preparation of standard mixture

Accurately weighed quantity of 1 gm Menthol, 1 gm Camphor and 4 gm Methyl Salicylate were transferred into separate 100 mL volumetric flasks; dissolved each in 50 mL of methanol and sonicated for 15 minutes. Final volume was made upto 100 mL with methanol of each flask to prepare standard stock solutions having 10000 μg/mL Menthol, 10000 μg/mL Camphor and 40000 μg/mL Methyl Salicylate concentrations. From those stock solutions, 6 mL of Menthol, 8 mL of Camphor and 10 mL of Methyl Salicylate were withdrawn from respective flasks and transferred into one common 100 mL volumetric flask and final volume was made up with methanol.

Preparation of test solution

The anti-arthritic spray sample was shaken well and 2 mL was withdrawn and transferred to 100 mL volumetric flask; dissolved in 50 mL of methanol and sonicated for 20 minutes. Final volume was made up to 100 mL with methanol.

Chromatographic procedure

Using ALS (Automatic Liquid Sampler) equipped with 10 µl syringe, 2 µl of standard solution and 2 µl of test solution were injected into gas chromatographic system under the operating conditions described above and chromatograms were recorded (Figures 2 and 3).

Assay

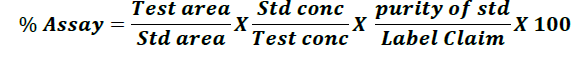

The individual solutions of Menthol (600 ppm), Camphor (800 ppm) and Methyl Salicylate (4000 ppm) were injected to the GC system with respect to developed chromatographic method and then sample solution was injected (Table 1). The area of the standard solutions as well as sample was determined and assay was performed by using following equation:

Method validation

Specificity: Specificity is a procedure to detect quantitatively the analytes of interest in presence of components that may be present in the sample matrix. Specificity was tested against standard compounds and in the formulation against potential interferences of excipients.

Linearity and range: The linearity is evaluated through a linear regression analysis. Linearity levels for Menthol, Camphor and Methyl Salicylate at range of 10-50 µg/mL, 20-60 µg/mL and 100-300 µg/mL respectively (as per their concentrations in formulation) were determined in terms of correlation coefficient (Figures 4-6) (Tables 2-4).

Accuracy: The analytical method should be able to recover actual amount of the analyte from the formulation. Accuracy was determined by calculating the %recovery by External Standard method in which three Placebo samples were taken and known amount of Menthol, Camphor and Methyl Salicylate were added in them at concentrations of 80%, 100% and 120% respectively. These solutions were injected in GC system and %Recovery was calculated. These were repeated 3 times and mean recovery was calculated (Tables 5-7).

Precision: Precision was considered at different levels.

Repeatability: Repeatability expresses the precision under same operating conditions over short interval of time. Take 0.1 mL of test solution in 100 mL volumetric flask and diluted up to mark with Methanol to get concentrations of 30 μg/mL Menthol, 40 μg/mL Camphor and 200 μg/mL Methyl Salicylate and analyze the procedure for 10 times and get the result (Table 8).

Intermediate precision: Intermediate precision was determined by analyzing the test solution (0.1 mL test sample in 100 mL Methanol) 10 times by different analysts and by same analyst in different days (day 1 and day 8) and %RSD was calculated (Tables 9 and 10).

Intraday precision: Intraday precision was determined by analyzing the test solution (0.1 mL test sample in 100 mL Methanol) 10 times in the same day and %RSD was calculated (Tables 11 and 12).

Robustness: The robustness of the method was established by making deliberate minor variations in the method parameters (Tables 13-15).

Change following parameters one by one and observe their effect on assay.

i. Change in mobile phase flow rate by ± 0.2 mL/min

ii. Change in initial oven temperature by ± 5 °C

System suitability: System suitability testing is an integral part of many analytical procedures. System suitability test parameters to be established for a particular procedure depend on the type of procedure being validated. Here, Resolution between all three peaks, Theoretical plates and Peak Asymmetry were calculated by injecting test samples 5 times and % RSD was calculated (Tables 16-18).

Assay

| Constituents | % Assay |

|---|---|

| Menthol | 99.97% |

| Camphor | 98.54% |

| Methyl Salicylate | 99.56% |

Table 1. Assay of developed formulation.

Specificity

No interference was detected at the retention time of Menthol, Camphor and Methyl Salicylate in sample solution.

Linearity and range

| Menthol | |

|---|---|

| Concentration | Peak Area |

| 0 | 0 |

| 10 | 33548 |

| 20 | 61339 |

| 30 | 89669 |

| 40 | 117476 |

| 50 | 144503 |

Table 2. Linearity and range of menthol.

| Camphor | |

|---|---|

| Concentration | Peak Area |

| 0 | 0 |

| 20 | 56922 |

| 30 | 89223 |

| 40 | 118385 |

| 50 | 144700 |

| 60 | 174320 |

Table 3. Linearity and range of camphor.

| Methyl Salicylate | |

|---|---|

| Concentration | Peak Area |

| 0 | 0 |

| 100 | 199567 |

| 150 | 305570 |

| 200 | 398666 |

| 250 | 506184 |

| 300 | 600486 |

Table 4. Linearity and range of methyl salicylate.

Accuracy

| Menthol | ||||||

|---|---|---|---|---|---|---|

| Sr. No. | % Level | % of menthol added in placebo | % Assay | % RSD | % Recovery | Average % Recovery ± SD |

| 1 | 80 | 81.35 | 80.89 | 0.4247 | 101.11 | 101.07 ± 0.1923 |

| 2 | 80.84 | 80.65 | 100.81 | |||

| 3 | 81.19 | 81.02 | 101.28 | |||

| 1 | 100 | 100.40 | 100.78 | 0.4587 | 100.78 | 100.09 ± 0.4452 |

| 2 | 100.69 | 99.43 | 99.43 | |||

| 3 | 100.28 | 100.07 | 100.07 | |||

| 1 | 120 | 121.00 | 120.62 | 0.3013 | 100.51 | 100.50 ± 0.4558 |

| 2 | 120.74 | 121.26 | 101.05 | |||

| 3 | 121.20 | 119.92 | 99.93 | |||

| Mean % Average Assay | 100.55 ± 0.4007 | |||||

Table 5. Recovery study of menthol.

| Camphor | ||||||

|---|---|---|---|---|---|---|

| Sr. No. | % Level | % of camphor added in placebo | % Assay | % RSD | % Recovery | Average % Recovery ± SD |

| 1 | 80 | 80.58 | 80.14 | 0.6126 | 100.17 | 99.85 ± 0.6042 |

| 2 | 80.75 | 79.20 | 99.00 | |||

| 3 | 80.84 | 80.29 | 100.37 | |||

| 1 | 100 | 100.32 | 99.91 | 0.5126 | 99.91 | 99.69 ± 0.4602 |

| 2 | 100.25 | 100.12 | 100.12 | |||

| 3 | 100.16 | 99.05 | 99.05 | |||

| 1 | 120 | 120.24 | 120.13 | 0.1788 | 100.11 | 100.24 ± 0.1481 |

| 2 | 120.28 | 120.20 | 100.16 | |||

| 3 | 120.34 | 120.54 | 100.45 | |||

| Mean % Average Assay | 99.93 ± 0.4041 | |||||

Table 6. Recovery study of camphor.

| Methyl Salicylate | ||||||

|---|---|---|---|---|---|---|

| Sr. No. | % Level | % of camphor added in placebo | % Assay | %RSD | % Recovery | Average % Recovery ± SD |

| 1 | 80 | 80.05 | 80.16 | 0.4696 | 100.20 | 99.68 ± 0.4849 |

| 2 | 80.08 | 79.23 | 99.03 | |||

| 3 | 80.07 | 79.84 | 99.80 | |||

| 1 | 100 | 100.06 | 99.92 | 0.3464 | 99.92 | 100.34 ± 0.3358 |

| 2 | 100.07 | 100.35 | 100.35 | |||

| 3 | 100.08 | 100.74 | 100.74 | |||

| 1 | 120 | 120.09 | 119.67 | 0.2747 | 99.73 | 99.82 ± 0.2838 |

| 2 | 120.10 | 119.44 | 99.53 | |||

| 3 | 120.07 | 120.25 | 100.21 | |||

| Mean % Average Assay | 99.95 ± 0.3681 | |||||

Table 7. Recovery study of methyl salicylate.

Precision

Repeatability

| Sr. no. | Menthol | Camphor | Methyl salicylate | |||

|---|---|---|---|---|---|---|

| RT (min) | Peak area | RT (min) | Peak area | RT (min) | Peak area | |

| 1 | 6.867 | 89651 | 7.362 | 117294 | 9.355 | 397922 |

| 2 | 6.878 | 88852 | 7.36 | 118485 | 9.362 | 398568 |

| 3 | 6.861 | 89769 | 7.366 | 118395 | 9.351 | 397025 |

| 4 | 6.861 | 89689 | 7.372 | 119285 | 9.354 | 398190 |

| 5 | 6.869 | 89702 | 7.365 | 117385 | 9.361 | 398126 |

| 6 | 6.864 | 89569 | 7.369 | 118402 | 9.36 | 397590 |

| 7 | 6.873 | 88669 | 7.362 | 118345 | 9.359 | 399489 |

| 8 | 6.865 | 89675 | 7.364 | 116585 | 9.36 | 389012 |

| 9 | 6.871 | 88969 | 7.37 | 118485 | 9.355 | 398663 |

| 10 | 6.868 | 90193 | 7.365 | 119385 | 9.356 | 389564 |

| Mean | 6.8677 | 89473.8 | 7.3655 | 118204.6 | 9.3573 | 396414.9 |

| SD | 0.00508 | 455.2893 | 0.00364 | 832.8762 | 0.003407 | 3619.129 |

| %RSD | 0.0739 | 0.5088 | 0.0494 | 0.7046 | 0.0364 | 0.9129 |

Table 8. Repeatability

Intermediate precision

Day 1 of interday precision and analyst 1 precision are considered to be same as repeatability.

| DAY–VIII, ANALYST-I | ||||||

|---|---|---|---|---|---|---|

| Sr. no. | Menthol | Camphor | Methyl salicylate | |||

| RT (min) | Peak area | RT (min) | Peak area | RT (min) | Peak area | |

| 1 | 6.865 | 89640 | 7.360 | 117405 | 9.354 | 398129 |

| 2 | 6.877 | 88765 | 7.361 | 118398 | 9.362 | 398568 |

| 3 | 6.881 | 88799 | 7.366 | 118612 | 9.351 | 397025 |

| 4 | 6.879 | 89486 | 7.372 | 119081 | 9.355 | 398190 |

| 5 | 6.864 | 89512 | 7.385 | 117854 | 9.371 | 398126 |

| 6 | 6.865 | 88956 | 7.369 | 118366 | 9.360 | 397590 |

| 7 | 6.870 | 89570 | 7.362 | 117447 | 9.349 | 399489 |

| 8 | 6.866 | 87999 | 7.364 | 118476 | 9.345 | 389012 |

| 9 | 6.876 | 88406 | 7.370 | 118333 | 9.355 | 398663 |

| 10 | 6.869 | 89454 | 7.365 | 118994 | 9.356 | 389564 |

| Mean | 6.8712 | 89058.7 | 7.3674 | 118296.6 | 9.3558 | 396435.6 |

| SD | 0.006129 | 534.4996 | 0.00696 | 544.2794 | 0.006911 | 3628.27 |

| %RSD | 0.0891 | 0.6001 | 0.0944 | 0.4600 | 0.0738 | 0.9152 |

Table 9. Interday precision at day 8.

| ANALYST-II | ||||||

|---|---|---|---|---|---|---|

| Sr. no. | Menthol | Camphor | Methyl salicylate | |||

| RT (min) | Peak area | RT (min) | Peak area | RT (min) | Peak area | |

| 1 | 6.860 | 90177 | 7.372 | 117899 | 9.364 | 398875 |

| 2 | 6.864 | 89635 | 7.368 | 117885 | 9.356 | 398112 |

| 3 | 6.859 | 89225 | 7.370 | 119045 | 9.365 | 389898 |

| 4 | 6.861 | 90368 | 7.371 | 117466 | 9.360 | 398853 |

| 5 | 6.861 | 88996 | 7.378 | 119154 | 9.359 | 398213 |

| 6 | 6.864 | 89235 | 7.369 | 117980 | 9.358 | 397562 |

| 7 | 6.865 | 89534 | 7.368 | 118036 | 9.365 | 395633 |

| 8 | 6.860 | 89662 | 7.370 | 119256 | 9.359 | 398863 |

| 9 | 6.863 | 89457 | 7.361 | 118622 | 9.368 | 386900 |

| 10 | 6.862 | 90111 | 7.368 | 118765 | 9.368 | 398876 |

| Mean | 6.862 | 89640.0 | 7.370 | 118410.8 | 9.362 | 396178.500 |

| SD | 0.0019 | 428.5340 | 0.0040 | 599.6747 | 0.0041 | 4056.2496 |

| %RSD | 0.0280 | 0.4781 | 0.0544 | 0.5064 | 0.0437 | 1.0238 |

Table 10. Intermediate precision by analyst 2.

Intraday precision

| DAY–I, ANALYSIS-I | ||||||

|---|---|---|---|---|---|---|

| Sr. no. | Menthol | Camphor | Methyl salicylate | |||

| RT (min) | Peak area | RT (min) | Peak area | RT (min) | Peak area | |

| 1 | 6.861 | 89888 | 7.369 | 118645 | 9.361 | 398850 |

| 2 | 6.862 | 88354 | 7.368 | 117840 | 9.359 | 389523 |

| 3 | 6.861 | 88569 | 7.370 | 118752 | 9.361 | 397564 |

| 4 | 6.870 | 89567 | 7.366 | 116662 | 9.357 | 398047 |

| 5 | 6.871 | 89043 | 7.368 | 118003 | 9.362 | 398856 |

| 6 | 6.869 | 90111 | 7.363 | 118753 | 9.367 | 398740 |

| 7 | 6.872 | 88045 | 7.370 | 119874 | 9.359 | 398500 |

| 8 | 6.870 | 90256 | 7.372 | 118630 | 9.355 | 398014 |

| 9 | 6.861 | 89114 | 7.367 | 118554 | 9.368 | 386483 |

| 10 | 6.865 | 88236 | 7.368 | 118976 | 9.357 | 389711 |

| Mean | 6.866 | 89118.3 | 7.368 | 118468.9 | 9.361 | 395428.800 |

| SD | 0.0044 | 767.8271 | 0.0023 | 795.8635 | 0.0040 | 4577.5865 |

| %RSD | 0.0641 | 0.8616 | 0.0318 | 0.6718 | 0.0428 | 1.1576 |

Table 11. Intraday precision analysis 1.

| DAY-I, ANALYSIS-II | ||||||

|---|---|---|---|---|---|---|

| Sr. no. | Menthol | Camphor | Methyl salicylate | |||

| RT (min) | Peak area | RT (min) | Peak area | RT (min) | Peak area | |

| 1 | 6.868 | 89874 | 7.364 | 117459 | 9.359 | 397985 |

| 2 | 6.862 | 88463 | 7.369 | 117946 | 9.358 | 398457 |

| 3 | 6.860 | 89156 | 7.366 | 119350 | 9.360 | 398024 |

| 4 | 6.859 | 88687 | 7.368 | 118868 | 9.362 | 397843 |

| 5 | 6.865 | 90041 | 7.370 | 118705 | 9.361 | 397825 |

| 6 | 6.864 | 89337 | 7.365 | 117985 | 9.357 | 398051 |

| 7 | 6.868 | 89024 | 7.364 | 117563 | 9.368 | 389921 |

| 8 | 6.866 | 88647 | 7.368 | 118912 | 9.365 | 397853 |

| 9 | 6.862 | 90178 | 7.366 | 118175 | 9.358 | 386631 |

| 10 | 6.861 | 89630 | 7.372 | 119045 | 9.362 | 395530 |

| Mean | 6.864 | 89303.7 | 7.367 | 118400.8 | 9.361 | 395812.000 |

| SD | 0.0030 | 579.5888 | 0.0025 | 625.1182 | 0.0033 | 3912.0454 |

| %RSD | 0.0443 | 0.6490 | 0.0342 | 0.5280 | 0.0348 | 0.9884 |

Table 12. Intraday precision analysis 2.

Robustness

Robustness of menthol

| Condition | % RSD of MEN in Std mixture | % RSD of MEN in test | % Average Assay | %Difference in Assay |

|---|---|---|---|---|

| (1) Change in flow rate ± 0.2 mL/min | ||||

| 2.5 mL/min (Normal) | 0.3357 | 0.6964 | 100.08 | - |

| -0.2(2.3 mL/min) | 0.5095 | 0.3778 | 100.14 | 0.06 |

| +0.2(2.7 mL/min) | 0.1962 | 0.2887 | 100.59 | 0.51 |

| (2) Change in initial oven temperature 5 °C | ||||

| 125 °C (Normal) | 0.3357 | 0.6964 | 100.08 | - |

| -5(120 °C) | 0.1533 | 0.3829 | 99.98 | 0.1 |

| +5(130 °C) | 0.4570 | 0.1546 | 100.19 | 0.11 |

Table 13. Robustness of menthol.

Robustness of camphor

| Condition | % RSD of CAM in Std mixture | % RSD of CAM in test | % Average Assay | % Difference in Assay |

|---|---|---|---|---|

| (1) Change in flow rate ± 0.2 mL/min | ||||

| 2.5 mL/min (Normal) | 0.2608 | 0.2620 | 100.78 | - |

| -0.2(2.3 mL/min) | 0.2609 | 0.3405 | 99.99 | 0.79 |

| +0.2(2.7 mL/min) | 0.5106 | 0.5638 | 100.14 | 0.64 |

| (2) Change in initial oven temperature 5 °C | ||||

| 125 °C (Normal) | 0.2608 | 0.2620 | 100.78 | - |

| -5(120 °C) | 0.8100 | 1.2301 | 100.00 | 0.78 |

| +5(130 °C) | 0.8271 | 0.7622 | 100.70 | 0.08 |

Table 14. Robustness of camphor.

Robustness of methyl salicylate

| Condition | % RSD of MeS in Std mixture | % RSD of MeS in test | % Average Assay | % Difference in Assay |

|---|---|---|---|---|

| (1) Change in flow rate ± 0.2 mL/min | ||||

| 2.5 mL/min (Normal) | 0.7621 | 0.7526 | 100.08 | - |

| -0.2(2.3 mL/min) | 1.1732 | 1.1506 | 100.44 | 0.36 |

| +0.2(2.7 mL/min) | 0.6571 | 0.3179 | 101.04 | 0.96 |

| (2) Change in initial oven temperature 5 °C | ||||

| 125 °C(Normal) | 0.7621 | 0.7526 | 100.08 | - |

| -5(120 °C) | 0.6869 | 0.8176 | 99.46 | 0.62 |

| +5(130 °C) | 1.0876 | 0.3588 | 99.72 | 0.36 |

Table 15. Robustness of methyl salicylate.

System suitability parameters

| Sr. no. | Menthol | ||

|---|---|---|---|

| Resolution | Theoretical plates | Asymmetry | |

| 1 | 0 | 68054 | 1.10288 |

| 2 | 0 | 65986 | 1.09914 |

| 3 | 0 | 67843 | 1.09874 |

| 4 | 0 | 69331 | 1.10341 |

| 5 | 0 | 68877 | 1.09965 |

| Mean | 0 | 68018.200 | 1.101 |

| SD | 0 | 1150.8949 | 0.0020 |

| %RSD | 0 | 1.6920 | 0.1792 |

| Limit | >2 | >2000 | <2 |

Table 16. System suitability parameters for menthol.

| Sr. no. | Camphor | ||

|---|---|---|---|

| Resolution | Theoretical plates | Asymmetry | |

| 1 | 4.78 | 87571 | 1.00019 |

| 2 | 4.79 | 89631 | 0.99865 |

| 3 | 4.77 | 88014 | 1.00547 |

| 4 | 4.79 | 85122 | 1.01372 |

| 5 | 4.78 | 87103 | 0.99971 |

| Mean | 4.782 | 87488.2 | 1.003548 |

| SD | 0.0075 | 1457.5455 | 0.0056 |

| %RSD | 0.1565 | 1.6660 | 0.5587 |

| Limit | >2 | >2000 | <2 |

Table 17. System suitability parameters for camphor.

| Sr. no. | Methyl Salicylate | ||

|---|---|---|---|

| Resolution | Theoretical plates | Asymmetry | |

| 1 | 20.11 | 147311 | 0.87564 |

| 2 | 20.09 | 150744 | 0.90411 |

| 3 | 20.10 | 146682 | 0.89772 |

| 4 | 20.11 | 148134 | 0.89980 |

| 5 | 20.10 | 152365 | 0.91003 |

| Mean | 20.102 | 149047.2 | 0.89746 |

| SD | 0.0075 | 2160.0659 | 0.0117 |

| %RSD | 0.0372 | 1.4492 | 1.3031 |

| Limit | >2 | >2000 | <2 |

Table 18. System suitability parameters for methyl salicylate.

A simple, accurate, rapid and economic Gas Chromatographic method has been developed and validated for simultaneous estimation of Menthol, Camphor and Methyl Salicylate in developed anti-arthritic spray formulation. The method assured satisfactory linearity, accuracy and precision. The method is robust and % recovery in spray formulation is good. Analysis of sample containing Menthol, Camphor and Methyl Salicylate showed no interference from the other excipients and additives. The proposed method can be easily and conveniently adopted for routine quality control analysis.

• We hereby acknowledge Mr. H. M. Panchal, Dr. Atul Bedekar, Mr. Vinod Patanwala, Mr. Aniruddh Patil, Mr. Mangeshkumar Padame, Mr. Sandesh Shah, Mrs. Sheetal Rajurkar, Mr. Virendra Shah of ICPA Healthcare Products ltd. Ankleshwar, Gujarat for their timely help and knowledge sharing.

• We kindly acknowledge Shree Nanjibhai Vekaria for providing the facilities to carry out this research work.

[Crossref] [Google scholar] [Pubmed]

[Crossref] [Google scholar] [Pubmed]

[Crossref] [Google scholar] [Pubmed]