ISSN: 2320-0189

ISSN: 2320-0189

Fanhong W1*, Jiuyin P2*, Fapeng W1,2,3, Jun Z1, Manjie J1, Yuxun T1, Lianfeng S1, Zhaomin J1,4, Peng L1,4, Pengfeng M1, Jianying H1, Hua Y1

1Hangzhou Iron & Steel Group Co., Ltd, Zhonghang Monitoring & Testing Technology Research Institute Co., Ltd, Hangzhou, P.R. China

2Beihua University, Jilin Wood-based Materials Science and Engineering Key Laboratories, Jilin, P.R. China

3Laboratorio Zhejiang University, School of Materials Science and Engineering, Hangzhou, China

4Faculty of Engineering, Zhejiang A&F University, Hangzhou, P.R. China

Received date: 13/05/2019; Accepted date: 12/06/2019; Published date: 18/06/2019

Visit for more related articles at Research & Reviews: Journal of Botanical Sciences

Xylan extracted from corn cob is a new type of wood preservatives, which is not only harmless to humans and animals, but also no contaminating the environment. Through the extraction of corn cob xylan, anti-corrosion performance testing and compared with the CCA, the results show that: white rot fungus specimen weight loss rates were: 2.53% and CCA weight loss rates were 4.08%. In this paper, we carried out through cottonwoods of different states to measure, research and analyze the main chemical composition on their moisture content, benzene - alcohol extract content, lignin content and holocellulose content, which is for future improvement preservatives formulated to provide experimental data, through the comparison of chemical composition among different states of cottonwoods to find out how the effects of preservatives on cottonwood anticorrosive were. The experiments indicated that benzene-alcohol extractive contents of anticorrosion cottonwood and fresh cottonwood were close to 4.50% and 4.51%, while decayed cottonwood of benzene-alcohol content of drawn increased to 5.70%. Lignin contents of anticorrosion and fresh cottonwood were close: respectively, 22.10% and 22.55%, from 24.19% rotten cottonwood. The whole fiber content of Anticorrosion cottonwood, fresh cottonwood and decayed cottonwood were, respectively, 66.62%, 84.55% and 64.19%.

Preservatives, Xylan, Extraction rate, Weight loss, Xylan anticorrosive, Chemical composition.

Xylan is a new type of wood preservatives that people have not studied very well, and a handful of researchers are confined to the analysis of plant components [1]. Currently, alkaline and acid can both be used to extract xylan. Generally, we use alkaline to study the composition structure of the xylan in plants [2]. However, the heavy use of alkaline in industrial production will corrode equipments and cause environmental pollution. So acid is more suitable for extraction of xylan in industrial production. Further, the main component of hemi cellulose in plant is xylan, and 7% -32% of dry weight of plant is also xylan. Therefore, agricultural and sideline products rich in xylan (such as: corn cob 35% -40%, sugarcane bagasse 24% -30%, cotton seed shell 24% -32%, and birch 24% -32%) can be regarded as the main raw materials of producing xylan. Currently, the main raw materials for producing xylan are corn cob and sugarcane bagasse. In addition, the husk is also a preferred raw material, for husk contains 19% multipentose, and the main component of multi-pentose is xylan. The study on husk in China is still in infancy stage, so that the space of utilization is very large [3-8].

Zuolong Ding believed that the white rot fungus mycelium formed a variety of degrading enzymes in the cell, of which the main is lignin degrading enzymes, secondary is cellulose-degrading enzymes and hemi cellulose degrading enzymes, to degrade lignin, hemi cellulose and cellulose in the cell wall, as nutrition of wood-rotting fungi . White rot fungi can successfully degrade cell wall to the extent that their metabolism can take advantage of [9,10]. In the whole decadent process, the average polymerization degree of cell wall is gradually decreased by white rot fungi, and the wood solubility changes slightly.

In Weixing Zhou’s research, the backbone of xylan in wheat straw is composed of β-(1→4) wood pyranose group, while arabinosyl groups and glucuronic acid group are connected to xylosyl as a side chain group. Some researchers believe it has a branched chain according to the degree of polymerization of the xylan in wheat stem and the number of terminal groups in xylan macromolecules. For the data of glycosylation Ratio, the content of Arabinose group they required was similar to the previous studies, while the content of the sugar aldehyde group is higher [11-15].

The lignin content in poplar after a certain time of decomposition of six kinds of white rot fungi (fire Phellinus, shag cover bacteria, three-color leather tuck bacteria, winter intend polypore, partial swelling intends Trametes and blood-red dense volvatus) was studied by Zhixian Wu, and he studied the biodegradation mechanisms of wood white rot fungi on poplar lignin [16]. The test showed that: the decomposition ability on poplar lignin according to the percentage reduction of lignin, descending order as bloodred dense volvatus, partial swelling intends Trametes, three-color leather tuck bacteria, winter intends to polypores, shag cover bacterium, the fire wood layer volvatus; there is a multiple regression relationship among three quantities (the decomposition amount X1, X2 and decomposition time Y of the six kinds of white rot fungi on the poplar lignin and holocellulose); winter intends polypores is a wood white rot fungi that decompose more lignin than cellulose [17-22].

Materials

Corn cob, sodium hydroxide, sulfuric acid, 3,5 - dinitrosalicylic acid, phenol, sodium sulfite anhydrous, ethanol. HHS-heated water bath, vacuum dryer, digital temperature control electric sets, clean benches, 722N visible spectrophotometer, centrifuge, the LS series vertical pressure steam sterilizer, induction cooker, micro grinder.

Methods

The use of soda for extracting xylan

Take a certain amount of corn cob to add a certain amount of water, and then boiled them for 4 hours in an electric furnace. Filter, filtered residue. Add ethanol solution whose volume ratio is 1 (95%): 3. After a night, centrifuged for 10 minutes (3000 r/ min) and freeze-dried, the resulting product is the roughing goods of xylan.

DNS method to measure sugar content

The determination of the DNS reagent dosage and placement time: use the method of Multi-group Comparative Experiment, added different DNS reagent to the tubes containing 0.5ml glucose standard solution and set another blank experiment, placed in 100°C water bath, heated 5min and cooled, determined the absorbance of the sample at different times after the constant volume. How to configure a standard xylan solution: weighed xylan with electronic electricity (corresponding accuracy), heated it at 80°C until the weight no longer changes, and configured the xylan solution (1g/ml) [23].

Preparation of test specimens and bacteria decadent

Feeding wood and test bacteria: use the sapwood of Populus tomentosa, the size of 20 mm × 20 mm × 10 mm. Poplar is hardwood, thus, to use the white rot fungus (Trametes versieolor). The preparation of the medium: inoculated culture, open the clean benches ultraviolet sterilizing lamp 30 min, and close sterilizing lamp, then lit alcohol lamp, and take the alcohol (volume fraction of 70%) to clean hands and the outer wall of medium. Burn the inoculating loop in alcohol lamp and inoculated in the middle of the river sand sawdust medium. Extinguish alcohol lamp and close the fume hood. Place the inoculation test tube at constant temperature and humidity box in the 25°C. Culture for 10 days, samples can be placed in to be infected when the surface of culture medium in bottle is covered by mycelium.

Bacteria decadent

The weight of samples is constant; place them in steam sterilization for some time, under the condition of normal pressure, so that the moisture content of the sample reaches 40% to 60%. After cooling, add samples into the feeding wood covering with mycelia under sterile conditions, three pieces in each bottle. Then put them in an incubator for infection. Remove them after four weeks, scuff the mycelium and impurities in surface, dry to oven-dry, and weigh. The weight loss rate should be more than 25% after decadent experimental, otherwise re-test. Calculate the weight loss rate of each decadent specimen, and the formula is as follows:

Loss rate (%) = (W1-W2) × 100/W1

Where: W1——Absolute dry weight of the sample before the experiment, g;

W2——Absolute dry weight of the sample after the experiment, g.

Taken of samples for analysis

Using the pieces of wood that has been treated with preservatives and not treated, they must be placed for a year, and fresh small piece of poplar, cut into small slices, then cut into matchstick size, and then placed in the grinder to grind to fine that all through a 40 mesh sieve. Screened, air-dried the fine that through 40 meshes but not through a 60-mesh, stored in jars (1000 mL) with frosted glass stopper, leaving for analysis.

Determination of moisture content

Weigh 1 g sample accurately, put in flat bottle that is clean, dried and has constant weight, placed in an oven and dried at 105 ± 3°C for 4 hours. The flat weighing bottle was moved to a dryer, cooled a half hour was and weighed. Place it in an oven again, dry for 1 hour, and cool half an hour. Repeat this until the weight is constant.

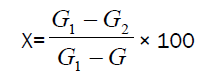

Moisture content (X) in%, calculated as follows:

Where: G ——Weight of flat bottle, g;

G1 ——Weight of flat bottle and sample before drying, g;

G2 ——Weight of flat bottle and sample after drying, g.

Three determinations at the same time, regard the arithmetic average as the measurement results, accurate to the second place after the decimal point, the error of two measurements should not exceed 0.2%.

Determination of pH

Open the power of acidity, preheating the equipment for half an hour, then corrected. 3 g sample was weighed (accurate to 0.01 grams), placed in a 50 ml breaker, added 30 ml distilled water that was new boiled and cooled to room temperature, stirred for 5min, stand for 15 minutes and then stirred for 5 min. Allowed to stand for 5 minutes, and the PH value was measured, accurate to 0.02. Each sample was measured three times in parallel, whichever is the arithmetic mean, filled in a form.

Determination of benzene - ethanol extractives content

Weighed 1 g, 2 g sample accurately, wrapped them with a piece of filter paper that pre-extracted by benzene - ethanol mixture, then placed in a Soxhlet extractor. Added benzene - ethanol mixture to exceed its overflow horizontal plane, fitted with condenser, and the instrument was placed in a water bath, the extent of heating to keep benzene - ethanol mixture in bottom flask boiling violently, the cycle of extract in an hour is not less than 4 times, and extracted 6 hours.

After extraction, filed condenser, remove the parcel containing a sample from the extractor with tweezers carefully, and then connected to the condenser and extraction, recovered part of the solvent until the bottom of the bottle remaining small amount of benzene - ethanol mixture.

Remove the bottom bottles, moved the contents to High vial that has been dried to constant weight, rinsed it 3 to 4 times with benzene - ethanol mixture, used a very small amount of the mixture each time, and poured into a weighing bottle. Heat the weighing bottle on a water bath to evaporate the excess solvent. Finally wipe the outside of the weighing bottle, placed in an oven and dried to constant weight at 10°C ± 3°C.

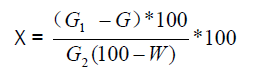

Benzene - ethanol extractives X, in%, calculated as follows:

Where, G1 ——weight of High vial, (g);.

G1——Weight of High vial together with the residue has dried, (g);

G2 ——Weight of air - dried sample, (g);

W ——Moisture in sample, (%).

Three determinations at the same time, regard the arithmetic average as the measurement results, accurate to the second place after the decimal point, the error of two measurements should not exceed 0.2%.

GC-MSD analysis of Benzene - Ethanol extracts

GC-MSD 6890N-5973 insert, Agilent

Chromatographic conditions: Capillary column DB-17MS, column length 30 m, inner diameter 0.25 mm, thickness 0.25 microns

Vaporization chamber temperature 260°C, carrier gas is helium, column flow 1 mL/min, not spitless, injection volume 1 μl

Column temperature: 80°C, remained 4 min, rose to 250°C with the speed of 10°C/min, remained 10 min GC-MSD interface temperature: 280°C

MS conditions: The ionization source EI, electron energy 70ev, ion source temperature 230°C, scan range: 15-500 amu (atomic mass units), NIST02 spectrum library

Determination of acid-insoluble lignin content in wood

Used the air - dried sample extracted by benzene – Ethanol, unlock the filter paper package, brushed it into 100 mL Erlenmeyer flask with ground glass stopper with a clean brush, added 15 mL sulfuric (72%) that pre-cooled to 12 ~ 15°C, plugged with cork, shaken for one minute, so that all the sample immersed in the acid, and then set at room temperature 2 hours, and frequently shaken contents in the Erlenmeyer flask.

After the arrival time, the contents of the flask were transferred to a 1000 ml beaker; purged conical flask with distilled water, all residues was washed into a beaker, and then diluted with water to an acid concentration of 3%. The amount of added distilled water, including the washing water, the total volume was 560 mL.

Heated to boiling 4 h on the electric furnace, put it aside so insoluble material deposited. Filter it with glass filter 1G2 that had a constant weight and washed it with distilled water to not acidic date. Then move the glass filter 1G2 together with the residue into a weighing bottle, placed in 105 ± 2°C drying to constant weight.

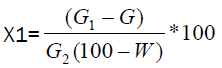

Calculated the acid-insoluble lignin content in wood, as follows:

Where:G ——The weight of the filter after drying (g)

G1——The weight of the dried filter together with residue (g)

G2 ——Weight of air - dried sample, (g);

W ——Moisture in sample, (%).

Three determinations at the same time, regard the arithmetic average as the measurement results, accurate to the second place after the decimal point, the error of two measurements should not exceed 0.2%. The sample needs to pre-extracted with benzene - ethanol solution and air-dried to use, the basis must be the oven-dry weight, calculate the weight of the sample.

Determination of the wood holocellulose

Used the air - dried sample extracted by benzene – ethanol, unlock the filter paper package, transferred into 250 mL Erlenmeyer flask, added 65mL distilled water, 10 drops (0.5 mL) of glacial acetic acid and 0.6 g sodium chlorate, placed in a 75°C constant temperature water bath, heated 1 h. Repeated three times, sample became white.

Finally, the flask was removed from the water bath, placed in water to cool. Filter it with glass filter 1G2 that had a constant weight and washed it with distilled water to not acidic date. And washed it three times with acetone, sucking washings, removed the filter, purge the filter external with distilled water to clean and placed in an oven at 105°C drying to constant weight. Cooled and weighed.

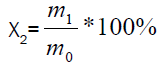

The holocellulose content in wood × 1 in%, calculated as follows:

Where, X2——Content of Holocellulose in wood raw material,% ;

m1 ——Content of dried holocellulose, g;

m0 ——Weight of oven dried sample, g.

Moisture content in wood and pH

Poplar in various state has been ground into the wood flour before experiment, and corrosion poplar and decadent aspen had been placed for more than one year, so the moisture content is generally low, both were low than 5%. PH value of the poplar in different state had a larger difference, the anticorrosive poplar is alkaline up to 9.82, both fresh aspen and decadent poplar were acidic. The huge differences of PH value between them may be due to preservatives. The concrete numerical values are shown in Table 1.

| Wood | The average moisture content (%) | PH |

|---|---|---|

| Fresh poplar | 5.08 | 6.38 |

| Anticorrosive poplar | 4.59 | 9.82 |

| Decadent aspen | 3.45 | 5.61 |

Table 1. Moisture content in wood and pH.

Wood fiber content

In woody plants, lignin is one of the main components in cell walls of the xylem and as filler and the adhesive substance in the wood. It can adhesive and reinforce the cellulose fibers in physical and chemical ways in the wood cell wall, to increase the mechanical strength and the ability of resistance to the erosion of microorganisms, and the lignified plant are upright and not easy to rot.

The holocellulose contains cellulose and hemicellulose, the current chemical mechanical pulp production may exploit its entirety substantially. Theoretically, the weight of holocellulose and lignin equal to 100% of the weight of the extract sample. However, writer cannot guarantee that all of the polysaccharide can be hydrolyzed into monosaccharides eluted in the measurement of lignin, and it cannot guarantee that all of lignin can be removed in the Holocellulose determination, so usually, the total content of holocellulose and lignin is greater than 100%. The values shown in Table 2 were the average of the values measured three times by the standard experimental procedure.

| Wood | Lignin content(%) | Holocellulose content (%) |

|---|---|---|

| Fresh poplar | 22.55 | 84.55 |

| Anticorrosive poplar | 22.10 | 66.62 |

| Decadent aspen | 24.19 | 64.19 |

Table 2. Wood fiber content

The data shows that the lignin content of the Anticorrosive poplar and fresh poplar are very close, indicating no major changes in the strength after xylanase anticorrosive processing. Wood needs to maintain the required strength in a long term, wood treated by Xylan preservative has this feature, which provided a favorable condition for xylan preservatives to be building materials preservatives. Although the lignin content in decadent poplar increased, but this increase is that the macromolecular lignin decomposed into small molecular lignin, so the binding force between the molecules reduced, instead reduced the strength of the timber. The decadent aspen is relatively loose, which can be seen from the raw materials.

The holocellulose content of Anticorrosive poplar and decadent aspen decreased significantly 10% more than fresher poplar, which shows that the Xylan preservatives is still not enough on preventing the decomposition of holocellulose, the wood structure would be losen, which makes the wood brittle, the strength would be impacted. If want the xylan preservatives to be a qualified building materials preservative, we need to improved formulation, strengthen the ability to prevent the decomposition of holocellulose. If the xylan preservatives is used in Biopulping, we also need to improve the ability to prevent the corruption of the holocellulose. What the pulp needed is a high content of holocellulose and a low content of lignin, so it is also necessary to improve in biopulping.

Benzene - ethanol extractives

Extract has an impact on the color, odor, taste, strength and permeability of the wood, gluing properties, paints, cutting tools, acoustic resonance. The extract of some species contains toxic substances, which may cause certain diseases to wood processing staff, so some appropriate measures should be taken when processing. The trees or wood contain toxic extractives have a strong natural decay resistance and have a remarkable resistance to corrosion for the wood-rotting fungi, termites and other bio. Extract is distributed in the heartwood, so the ability of decay resistance to corrosion is better than sapwood. This experiment only for the basic benzene - ethanol extract, and the results are shown in Table 3.

| Wood | Average content (%) |

|---|---|

| Fresh poplar | 4.41 |

| Anticorrosive poplar | 4.50 |

| Decadent aspen | 5.70 |

Table 3. Benzene - ethanol extractives `

It can be seen from the table that the benzene - ethanol extraction content is constantly increasing among fresh poplar, corrosion poplar and decadent aspen, the anticorrosive Poplar increased slightly than fresh poplar, but that in decadent aspen had a significant increase. Decadent aspen increased significantly due to producing a large number of pigments, so the color is significantly darker than the first two ones.

The presence of wood extracts not only affects the wood glue and pulp bleaching, but also caused a considerable amount of adhesives and bleach is wasted. Thus, the timber extract needs to be withdrawn before processing and use them effectively, which not only saves the wood processing, pulp and paper cost inputs, and can provide cheap and abundant raw materials for pharmaceuticals, light industry and chemical.

Chemical composition analysis of Benzene - Ethanol extract

The chemical composition is described in the following Figures 1-3.

Bagasse, rice husks, corn cobs and birch are widespread in nature, as raw materials, this article extracted xylan widely used in the industry. Then detected the antiseptic properties of four preservatives according to the relevant standard, and compared with CCA, the following conclusions:

(1) The optimum conditions of xylan soda extract: alkali concentration: 12%; solid-liquid ratio: 1:10; extraction time: 2h; extraction temperature: 100°C.

(2) Xylan preservatives have a preservative effect on mining versicolor bacteria, Weight loss rate are: bagasse xylan: 2.41%, rice husk xylan: 2.65%, corn cob xylan: 2.53% birchwood xylan: 2.33%, the weight loss of is 4.08%.

The work was financially supported by the National Natural Science Foundation of China General Program [31270589].