Page 34

conferenceseries

.com

RRJOMS | Volume 5 | Issue 4 | July, 2017

July 27-29, 2017 Vancouver, Canada

10

th

International Conference on

Emerging Materials and Nanotechnology

Nanocarbon composites for mechanical and barrier applications

Ken Bosnick

National Research Council Canada, Canada

N

anoscale allotropes of carbon, including carbon nanotubes (CNTs) and graphene nanoplatelets (GNPs), show a great deal of

promise as functional fillers in nanocomposite materials. The extreme linear aspect ratios, strong sp

2

carbon bonds, and high

chemical stability all contribute to making CNTs ideal reinforcement fillers for mechanical applications. Conversely, the high aspect

ratio planar nature of graphene and GNPs, along with their high impermeabilities, suggests applications as barrier materials. In this

talk, we discuss our work on CNT – aluminum oxide (AO) composites for mechanical applications, including as ballistic armour,

and GNP – polymer composites for high barrier applications, including oxygen barriers for food packaging and anti-corrosion

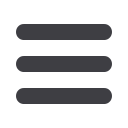

coatings. CNT – AO hybrid structures are produced by depositing CNTs as conformal coatings on various AO materials, including

powders and fabrics. The deposition is carried out in a large-volume chemical vapor deposition reactor, following a conformal catalyst

deposition from solution or via an atomic layer deposition process. The CNT – AO hybrids are sintered into composite materials

under high pressure and characterized for mechanical enhancements. Increase in fracture toughness of as high as 71% have been

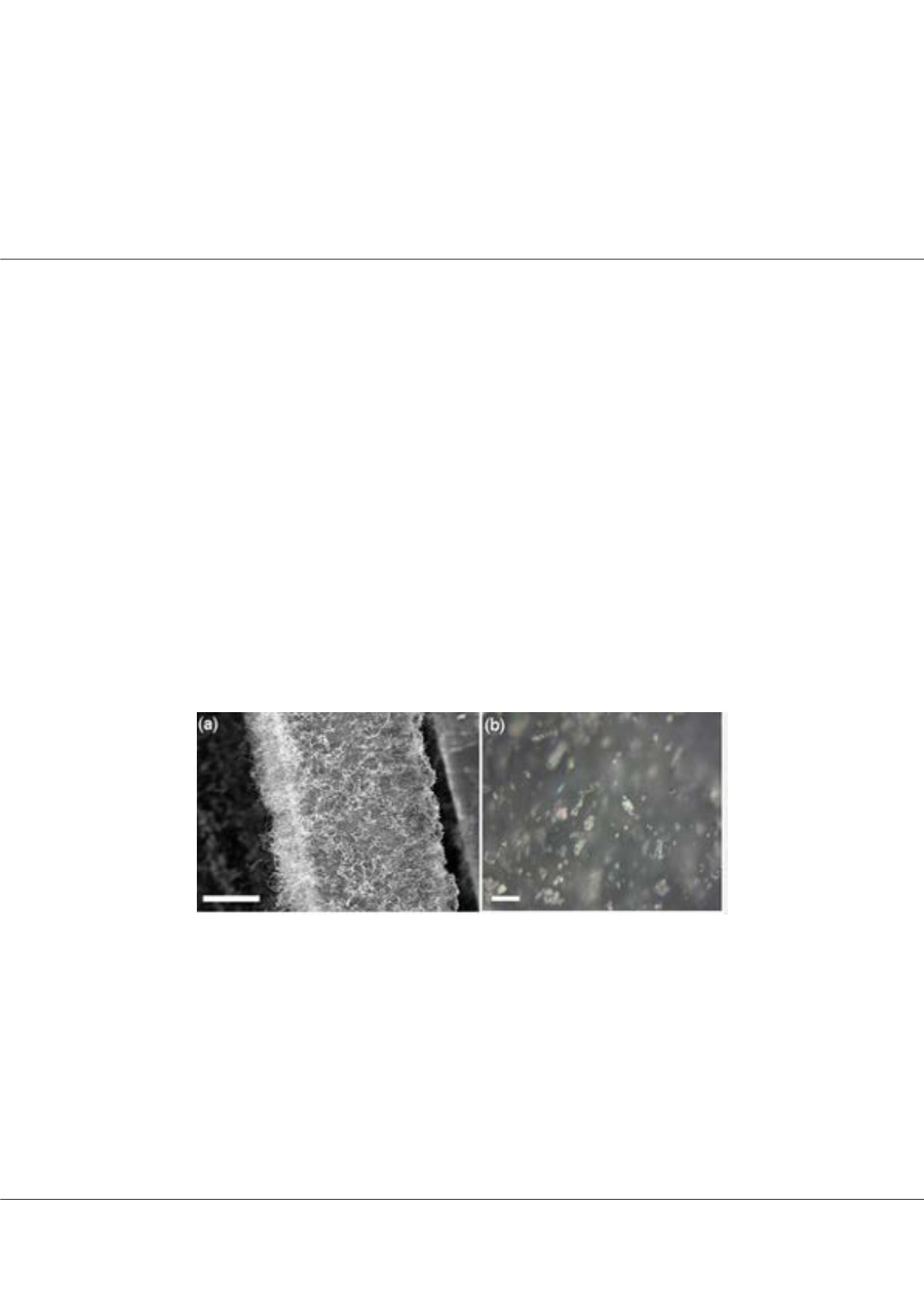

found from these CNT – AO composites. GNP materials are melt-processed with polyethylene (PE) and extruded into packaging

films, which are characterized for their oxygen transmission rates. It is found that the GNP – PE films show comparable oxygen

transmission rates to the neat PE films, indicating that further processing will be necessary to realize the desired enhancements. The

GNP materials are also solution processed with epoxy (EP), cast onto steel substrates, and cured to form coatings. The efficacy of these

coatings as anti-corrosion barriers is established by electrochemical and salt-fog corrosion tests. Early results suggest that the GNPs

are enhancing the anti-corrosion performance of the EP films.

Biography

Ken Bosnick is a Research Officer with the National Research Council (NRC) at the National Institute for Nanotechnology (NINT) in Edmonton, Canada. He is

currently leading or contributing to a number of projects involving nanocomposites. He is leading a large cross-NRC collaborative project through NINT aimed at

producing high-performing barrier films, such as for food packaging and anti-corrosion coating applications, by processing graphenic and cellulosic nanomaterials

with polymers. He is also leading a smaller project at NINT concerned with producing smart materials capable of sensing meat spoilage. For the Security Materials

Technology Program, he is developing new carbon nanotube/ceramic hybrids for processing into ceramic composites for armour applications, including conformal

metallic catalyst deposition by atomic layer and chemical vapor techniques.

ken.bosnick@nrc.caKen Bosnick, Res. Rev. J Mat. Sci. 2017

DOI: 10.4172/2321-6212-C1-002