ISSN: 2321-6204

ISSN: 2321-6204

Sudeep Shekhar, Joe J, Rahul Kumar, Jyothis J, Ketan Kumar RM, Priya YA, Jayaraj Rao K* and Pagote CN

DT Section, NDRI, Adugodi, Bangalore 560 030, Karnataka, India

Received date: 31/10/2012 Accepted date: 18/11/2012 Revised date: 10/11/2012

Visit for more related articles at Research & Reviews: Journal of Food and Dairy Technology

Dahi is a popular fermented Indian dairy product prepared by fermenting the milk by lactic acid bacteria. The texture of dahi depends mainly on the heat treatment given to milk. Cow milk (3.5% fat and 8.5% SNF) was subjected to two separate treatments: (1) heating at 63oC for 30 min and (2) boiling treatment without holding period. The milk was cooled to about 40oC and inoculated with Lactococcus lactis culture and incubated at 30oC for about 12 hours. The dahi formed was chilled to 5oC and evaluated for quality. Firmness, consistency and index of viscosity as measured by Texture Analyser increased with increased heat treatment and the highest values were observed in dahi prepared from boiled milk. Boiling treatment of milk resulted in least syneresis of whey in the curd. Based on the results, it was recommended that milk be subjected to boiling treatment to produce best quality dahi.

Dahi, Heat treatment, Milk, Rheological, Firmness, Consistency

Dahi is the most popular fermented dairy product in the Indian sub-continent and consumed by most people almost every day with each meal. It is similar to leben in Iran, Jugurt in Turkey, Roba in Iraq,Mazun in Armenia,Villi in Finland, Shosim in Nepal[1]. Its chemical composition is similar to that of laban in Saudi Arabia [2]. Dahi is so popular that a meal is considered incomplete without consuming it towards the end of the meal. In southern parts of India, dahi is eaten with rice (popularly known as curd rice) and is used to prepare several culinary dishes. The beneficial aspects of milk, dahi and other dairy products are well documented [3, 4, 5, 6, 7]. Bhattacharay and Das [8] isolated from dahi a few lactobacilli which produced bacteriocins effective against human pathogens. Thus, the therapeutic properties of dahi are well known, hence dahi is used in several of Ayurvedic formulations (traditional Indian medicinal system) [9, 10]. Dahi prepared from buffalo milk is white in colour and possesses firm body and slightly granular texture, whereas dahi prepared from cow milk is les firm and smooth in texture [11]. These differences are attributed to inherent variations in the protein make up of both the milks [12]. The huge market of dahi in the sub-continent is being tapped by most of the organized sector dairies. It is estimated that 6.9% of total milk produced in India is utilized for dahi production in India [1]. Still a large portion of market remains to be tapped. Dahi is also used as a vehicle to incorporate probiotics into the health conscious consumers because of the fact that it is consumed by people daily [13]. Varieties of dahi were also developed for the benefit of consumers, like fruit dahi [13]. Dahi is mostly sold in polythene pouches, but also in set form in HDPE containers. Dahi sold in pouches does not have the three dimensional network structures which is typical of set dahi. Whereas that sold in the rigid plastic containers possesses a firm body and smooth texture which appeals to consumers. However, flavour is the foremost quality of dahi that determines its acceptance. The pleasant flavour of dahi is attributed to its diacetyl content which is produced by lactic acid bacteria [1, 4]. Next to flavour, the acceptability is determined by the texture of the curd, which is governed by many factors including type of milk, composition of milk etc. [14] Heat treatment of milk also plays an important role in determining the textural quality of dahi by way of denaturation of milk proteins. Hence, a study was conducted to examine the effect of heat treatment on the quality of dahi.

Preparation of Dahi

Fresh cow milk was procured from Institute’s dairy farm and standardized to 3.5% fat and 8.5% SNF. The milk was heat treated to (i) 63oC for 30 min in water bath and (ii) boiling without holding on a gas stove. The milk was then cooled to about 40oC and added with starter culture @ 1% under sanitary conditions. The starter culture was procured from the Institute’s Dairy Bacteriology Unit and consisted of Lactococcus lactis sub sp. lactis and L. lactis subsp. diacetylactis organisms. The milk was slowly stirred to distribute the culture organisms uniformly throughout the milk and the inoculated milk was poured into 250 ml capacity beakers which were then incubated at 30oC for about 12 h. After fermentation, the beakers were shifted to refrigerator to cool the curd for about 24 h so that it was cooled to about 5oC. The curd (dahi) was then analysed for sensory quality, rheological attributes and physico-chemical attributes.

Analyses

Sensory:

The chilled dahi (5oC) was served to a panel of seven judges and its colour and appearance, flavor, body and texture and overall acceptance were evaluated on 9- point Hedonic scale [15]. The sensory evaluation was conducted in Sensory Evaluation Laboratory of the Institute under fluorescent lights. The sensory acceptance data were tabulated by taking average of scores awarded by all the judges for different treatments in three replications.Physico-chemical:

The dahi was analysed for the following physico-chemical properties:Syneresis:

The set dahi at 5oC was slowly transferred to 15- ml capacity centrifuge tubes causing minimum disturbance to the coagulum. The centrifuge tubes were balanced by adjusting their weights and centrifuged at 2000 RPM in a Remi centrifuge for 5 min. The quantity of whey separated at the top of the coagulum inside centrifuge tubes was recorded as millilitres. The higher the volume of whey separated, the higher was the syneresis and vice versa.pH:

pH was determined by potentiometric method i.e. by potential difference between the sample and electrolyte solution present inside the electrode of pH meter, using digital pH meter (Systronic Co., Bangalore). The electrode of the pH meter was directly dipped in the set dahi and the pH was recorded (5oC).Acidity:

The acidity of the dahi samples was analysed by BIS method and expressed as per cent lactic acid[16].Rheological:

Firmness, consistency and viscosity of dahi are important rheological or textural parameters that govern the quality of dahi. These attributes can be measured objectively by Texture Analyser or cone penetrometer. The following method was employed for measuring firmness, consistency and index of viscosity by Texture Analyser (Stable Microsystems, UK). The Texture Analyser works based on the principle that a cylindrical steel probe penetrates into the dahi samples and experiences resistance during the penetration. The resistance offered by the dahi sample (5oC) during the penetration of the probe up to a specified distance is recorded as firmness (Newtons) of dahi. During this operation, force - time curve is generated. The area under the positive curve is taken as consistency (Newton.sec) and the area of the negative curve is taken as index of viscosity (Newton.sec). Since Texture Analyser cannot measure the viscosity in terms of centipoise, the negative pull exerted by the dahi sample on the probe during withdrawal is taken as index of viscosity in terms of Newton.sec (Fig.1).

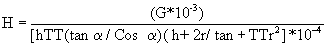

Cone penetrometer is a simple and useful instrument for determining the firmness or hardness of food materials. It was primarily developed for the hardness of crystalline fats [17]. In this instrument, a conical metal probe is allowed to freely fall into the sample for a specified time, for example 5 sec. Then its fall is arrested by an electromagnetic mechanism and the depth of penetration is measured on a dial scale and expressed as (x 0.1) mm. The higher the depth, the softer is the dahi sample and vice versa. Since, dahi is a soft sample, metal probe would be too heavy for the purpose, so a rubber conical probe was used. The penetration depth was converted into hardness by the following formula [17].

Where, H= hardness (kg/cm2 )

G=weight of cone assembly (g)

A=area of impression (cm2)

h= Depth of penetration (0.1mm)

α=half of cone angle (α for rubber cone= 24o and α for metal cone =15o)

r=radius of flat tip of cone

Statistical:

The sensory evaluation data was subjected to one way ANOVA (analysis of variance) to separate the true effect of heat treatment on the sensory quality of dahi, by MS Excel Programme - 2007 version. The critical difference was computed to find out the statistical significance between any two treatments [18].Effect of heat treatment on the textural properties: The rheological parameters of dahi were significantly influenced by heat treatment of milk used for dahi making. It was noted from the Texture Analyser parameters that by the heat treatment of milk the firmness of dahi increased from 0.039 N in no heat treatment (control) to 0.110 N in the dahi prepared from boiled milk (Fig.2 a). The LTLT treated milk dahi had 0.070 N firmness. Similar observations were recorded with consistency value, but LTLT treatment (0.33 N.sec) and boiled milk dahi (0.31 N.sec) displayed almost same consistency, yet much higher than that of conrol (0.071 N.sec) (Fig. 2 b). Index of viscosity values were lower for control dahi (0.0012 N.sec) whereas that for LTLT treated milk dahi and boiled milk dahi were 0.007 and 0.012 N.sec, respectively (Fig.2 c). This trend was reflected in the parameters measured by cone penetrometer also. Fig. 3a shows that the control sample had higher depth of penetration value (424 mm-1) than heat treated samples. Boiled milk dahi (258.3 mm-1) exhibited least depth of penetration. Similar trend, but in reverse, was obtained with the hardness values expressed as kg per cm2 (Fig. 3b). The higher the depth of penetration, softer is the product. This is also supported by the statement of DeMan et al. [17] It is evident that the trend of results obtained by Texture Analyser and cone penetrometer was the same. Penetrometer is a simple instrument especially developed for measuring the hardness of fats crystalline in nature [17]. This instrument was also used to measure the hardness of various other products[19]. In the present study also this instrument was useful in measuring the hardness of dahi. The principle of penetrometer is that when cone is allowed to freely fall into the product, it penetrates into the product and comes to stop when the resistance offered by the food equals the yield stress of the product [17]. So the penetration value not only reflects hardness but also is a measure of the yield stress of the product. For the same reason, the depth of penetration can also be converted to hardness value in terms of kg per cm2 [17]. The penetration depth of dahi samples were also converted into hardness.

The effect of heat treatment of milk on the rheological parameters could be attributed mainly to the denaturation of proteins. In milk the casein exists in colloidal state which is sustained by calcium bridges between the casein micelles [20]. The whey proteins exist in soluble state and have no interaction with casein micelles [20]. But by heat treatment of milk as mentioned in the present study, the whey proteins get denatured and involve in interaction with casein micelles without affecting the calcium bridges. These observations extend support to the results obtained in the present study. The results indicate that as intensity of heat treatment given to milk increased, more and more casein-whey protein interactions took place. However, during fermentation process, the calcium bridges between the protein particles dissolve because the calcium goes from colloidal state to solution state as the acidity rises and pH decreases [21]. It also results in the slow precipitation of the casein-whey protein particles. Similar change is expected to happen during fermentation of milk in dahi manufacture. The precipitated casein-whey protein particles arrange themselves in specific manner forming three dimensional networks which imparts firmness to dahi. This network can easily be broken by subtle forces of agitation, but once broken, the network cannot be built back. However, part of the original viscosity may be recovered during storage which is known as thixotropic character. The sticky character acquired by the curd during fermentation is responsible for the thixotropic character and could be attributed to mucilaginous substances produced by starter bacteria [22]. This is the reason why it is widely believed in the subcontinent that the milk should not be disturbed while setting of milk is in progress otherwise firm curd would not form. Disturbing the milk during setting means disturbing the network being formed during acid production. A firm, well set curd is most preferred than stirred curd in India. However, most of the curd sold is stirred curd because of convenient processing steps, but manufacturers are realising the people’s preference for set curd, so set curd with a thick, firm consistency is now gaining market. In this regard, extent of heat treatment of milk and use of starter cultures which produce not only lactic acid and diacetyl, but also mucilaginous compounds are important. It should be noted that the production of mucilaginous substances by the LAB is a genetic factor controlled by plastids [22] which are major cell organelles. Khalifa et al. [23] advocated application of inulin and mucilaginous substances for improving the consistency of yoghurt, whereas Mumtaz et al.[24] used xylooligosaccharides for the purpose. The observations of these workers show that apart from heat treatment, external polysaccharides could also be employed to enhance the consistency of products like dahi.

Another factor which governs the firm body and texture of set dahi is the intensity of heat treatment given to milk which influences extent of denaturation. Isanga and Zhang [25] stated that during yoghurt manufacturing, the thermal processing of milk (90-95oC / 5 min) dentures whey proteins which consist of alpha lactalbumin and beta lactoglobulin. The denatured whey proteins interact with casein micelles by coating on their surface [20]. The denatured whey proteins have a good water binding ability, so enhance the thickness of the curd. They also help in sustaining the three dimensional structure of dahi. It is known that whey proteins denaturation begins at 65oC and would almost completely be denatured (93-95%) by heat treatment of milk at 80oC for 45 min [26]. The water binding ability of proteins is maximum only when they are partially denatured i.e. when the protein structure is not completely damaged. This is because of exposure of hydrophilic groups which were otherwise remaining embedded inside the tertiary or quaternary structure [27]. But when milk is intensely heat treated as in heat- sterilisation i.e. more than 10 psi, then whey proteins are completely denatured, their secondary structure is fully straightened out and the hydrophilic groups are lost; as a result the proteins lose the water binding ability. So, sterilisation of milk is detrimental to the curd firmness. It is now clear that boiling the milk without holding will not lead to complete damage to the secondary structure of whey proteins, but results in only partial uncoiling leading to more number of hydrophilic groups being exposed. Thus, water binding ability is increased.

Effect of heat treatment on the syneresis and acid development in dahi:

Syneresis is the separation of whey from the curd and expressed as ml as depending on the method followed. Extent of syneresis is indicative of the quality of dahi. Consumers prefer dahi with no visible whey separation. Presence of separated whey indicates excessive fermentation and stored dahi. So consumers tend to think that the curd showing whey separation is not fresh and hence not good. Dahi prepared from raw milk showed visible whey separation measured as 7.7 ml after centrifugation (Table-1). LTLT milk dahi displayed syneresis value of 7.2 ml which was also visible. However, boiled milk dahi exhibited no visible whey separation and was of firm consistency. By centrifugal method followed in the study, it exhibited 6.8 ml syneresis, which can be considered as significantly less. The pH of boiled milk dahi (4.20) was slightly higher than that of raw milk dahi (4.11) and LTLT milk dahi (4.14). Panesar and Shinde [28] reported a syneresis value of 4.7% for fresh Aloe vera incorporated yoghurt, which is comparatively lower than the value obtained in the present study (6.8 ml). This can be attributed to the incorporation of Aloe vera in the yoghurt preparation. The acidity of dahi prepared from boiled milk was 0.79 % LA which was more than in control dahi (0.65%) and LTLT heated milk dahi (0.68%). However these values are not indicative of effect of heat treatment, because heat treatment is not known to affect the acidity development. It may be noted that in case of dairy products there is no proportional relationship between pH and acidity because of buffering capacity of milk solids. During incubation, the LAB multiplies and grows logarithmically and utilizes a fraction of lactose converting into lactic acid. This results in increase in acidity and decrease in pH of curd. This brings about changes in the state of inoculated milk because changes taking place with regard to the milk proteins. In dahi, the pH ranges from 4.6 to 5.02. As per BIS standards, dahi should contain 0.7% acidity.

When well set curd is disturbed, the whey flows through the channels in the network and finally separates out. This is called syneresis. The partially denatured proteins for the reasons discussed above holds more moisture or whey, so syneresis is less in the curds prepared with high heat treated milk (boiling). In case of raw milk, the whey proteins are in native state so possess low water binding ability, hence more syneresis is expected to take place in that curd. In LTLT treated milk, the whey protein denaturation has just begun so water binding was slightly to a greater extent than in raw milk (control). Thus, less syneresis was observed. In boiled milk, the proteins held more moisture and tightly too, so gave low syneresis values. Thus, firmer the curd, lower the syneresis and vice versa.

Effect of heat treatment on sensory quality and acceptance of dahi:

The acceptability of dahi samples was measured on 9- point Hedonic scale. Boiled milk dahi scored highest in all the sensory attributes. The milk which was not heat treated resulted in dahi with low sensory scores that were about 6.0 or below i.e. ‘’like slightly’ or less (Table-2). The LTLT heat treated dahi scored better than raw milk dahi indicating that flavour and body and texture improved by heat treatment. By heat treatment, the undesirable organisms were killed and LAB grew without competitive inhibition and when milk was boiled the same happened but because of protein-protein interaction body and texture improved further which might have synergistically enhanced the flavour attribute. For these reasons, the overall acceptance scores were highest for the boiled milk dahi. The statistical analysis showed that the effect of heat treatment was significant at 5% level of significance for all the sensory attributes. The F-values for color and appearance, flavour, body and texture and overall acceptance were 13.2, 22.5, 18.5 and 16.6, respectively. These were far higher than F-critical value (2.660) indicating that heat treatment had significant effect even at 1% level of significance.

It was concluded that for obtaining best quality dahi, milk has to be heat treated to boiling temperature so that optimum flavour, appearance and body development could take place during fermentation. Low Temperature Long Time heat treatment of milk also resulted in acceptable quality of dahi.