ISSN: 2321-6204

ISSN: 2321-6204

Meena Mehta*

Department of Food Science & Nutrition, Dr. B.M. Nanavati College of Home Science, 338 R.A. Kidwai Marg, Matunga, Mumbai 400 019 India

Received date: 23 February 2014; Accepted date: 26 March 2014; Revised date: 18 March 2014

Visit for more related articles at Research & Reviews: Journal of Food and Dairy Technology

In the 21st century fast food and junk foods claim increasing demand of cheese and its variety. However, quality of cheese, consumption pattern and its fatty acid composition do affect the health. The basic cheese processing unit deals with biological fermentation with different friendly bacteria. Other physical parameters like pH, temperature and isolation unit has positive effect on quality and shelf life of the cheese. It also affects the fatty acid composition of final products. An attempt was made to evaluate the quality of cheese with respect to fatty acid composition of branded cheese. The effect of pH and temperature variant was correlated with the quality. An optimum technical condition is recommended to synthesize the cheese with improved the fatty acid composition in particular with omega acid inclusions.

Cheese, Ingredients, Processing conditions

Cheese has formed a staple part of the human diet for many centuries and references to its manufacture are to be found in early classical literature. Description also occurs in many old British books, especially in those dealing with farm practice in specific areas of England, Scotland and Wales [1]. Cheese like butter, functions as the balance wheel of the dairy industry. The world’s recorded annual cheese production in 1969 has been estimated to be 6.8 million tones. Several categories [2] of hard, semi-soft and soft cheeses exist as natural cheeses. Cheddar, Mozzarella, Romano, Blue, Parmesan, Cream are produced without processing or adding other ingredients, while pasteurized processed cheese, spread entails further addition of ingredients and pasteurization. An insignificant amount of milk is annually converted into cheese in India, mainly of the cheddar type [4].

Cheese may be defined as the fresh or matured product made by coagulating or a combination of any of the following substances, namely milk, cream, skimmed milk, partly skimmed milk, concentrated milk, reconstituted dried milk and butter milk, and then partially draining the whey resulting from any such coagulation. Cheese substitutes and cheese analogs, made from either dairy and/or non-dairy ingredients, do not have standard identities but chemical and physical properties exist in the form of fat and moisture.

Cheese making [3] is a very convenient method for converting a considerable part of the milk nutrients into a product that is less bulky, will keep well, is of a high nutritive value and is palatable and easily digestible. Cheese are made from a variety of different milks, cows, sheep, goats, buffalo, etc. by different methods of manufacture, are ripened for different periods of time in different conditions. It will differ by color, texture, hardness, odor and taste3. Cheese is not shelf stable [5] at room temperature and requires special packaging and refrigeration during all phases of handling and marketing.

Assessment of cheese quality is essential in order to determine if the cheese conforms to legal standards, meets the requirements of the buyer and ultimately the customer and to grade the cheese for payment. A cheese may meet all legal and safety requirements [6] but have appearance, flavour and or texture defects that make it unsuitable for consumer use.

An exhaustive market survey was planned to understand the consumption pattern and demand for a particular brand of cheese. Based on the initial survey report, a scientific investigation was carried out with respect to quality of the cheese and its sensory evaluation. Physical and chemical composition of the branded cheese was determined. A sincere effort was made to synthesize the cheese with modified technical conditions particularly with respect to mother culture and ageing process. A newly synthesized cheese was evaluated for its nutritional advantages.

• To conduct a consumer survey on 500 consumers of different age groups to find out the popular brands and understand the consumption pattern.

• To conduct a market survey for 100 shops to find out preference of selling most popular brand.

• To conduct chemical analysis of certain branded cheese namely Britannia, Le Bon, Laughing Cow, Philadelphia, Le Super Be, to check out the Fatty acid composition, Proteins, Moisture, Sodium Potassium content and its ratio.

• To conduct microbial analysis of Britannia, Le Bon, Laughing Cow, Philadelphia, Le Super Be, cheese sample was carried out for the following parameters like Total Coliforms group, Yeast and Mould counts.

Market survey

Market survey was conducted by personal interview with the help of pre-planned questionnaire. A pre-design form was used for conducting interview with randomly selected shopkeepers and families in different areas of the Mumbai city.

Chemical analysis of selected cheese

Ten different brands of popular cheese were analyzed for their composition. Various parameters like moisture, ash, acidity, salt, minerals, fatty acid and protein. Moisture was determined by Karl Fischer’s method while total ash was determined by isothermal heating experiment. Total salt was determined by titrating water extract using Mohr’s method. Total acidity was determined by acid-base titration. A Kjeldahl’s method was used to determine total nitrogen in the form of protein and Gas chromatogram technique was used for the determination of fatty acid from cheese. Selected minerals like Ca, Mg, Na K, P composition were investigated either by complexometric titration or by flame photometry method. P was determined by colorimetry.

Microbial analysis of selected cheese

Samples of each popular brand cheese were examined for their microbial status. A Standard Plate Count method was used for the purpose. Each investigation was performed in triplicate to ascertain reproducibility of the examination.

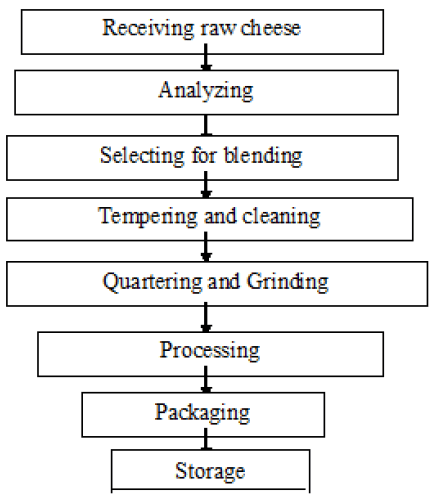

Production of cheeses with modified conditions7

The milk is heat treated to kill off any harmful bacteria that may be present. Starter cultures of special bacteria are then added to the milk and their growth “ripens” the milk and helps to develop the desired flavors and aromas. Rennet is then added to the milk which helps it to coagulate and turn into curds and whey. Rennet is artificially produced from vegetarian sources. The curds and whey are then heated to a high temperature and salt is added to produce the correct texture and flavor. The cheese is then pressed to force out the whey and to give it its final shape. The cheese is then left to mature and the longer the cheese is left in storage the more mature the flavor becomes. The process flow chart is as follow.

The results of all the above experiments are tabulated and summarized in the tabular form and discussed in tune with the existing scientific standards. The results are also expressed in the graphical mode to understand the trends and variation with each brand.

Numerous different cheeses are now available on the market and it is one of the most versatile, economical and nutritious foods consumed within our diet. Cheese making was introduced into Britain by the Romans. The most famous British cheese is cheddar and most British cheeses are hard-pressed varieties although soft cheeses like cottage cheese are also popular.

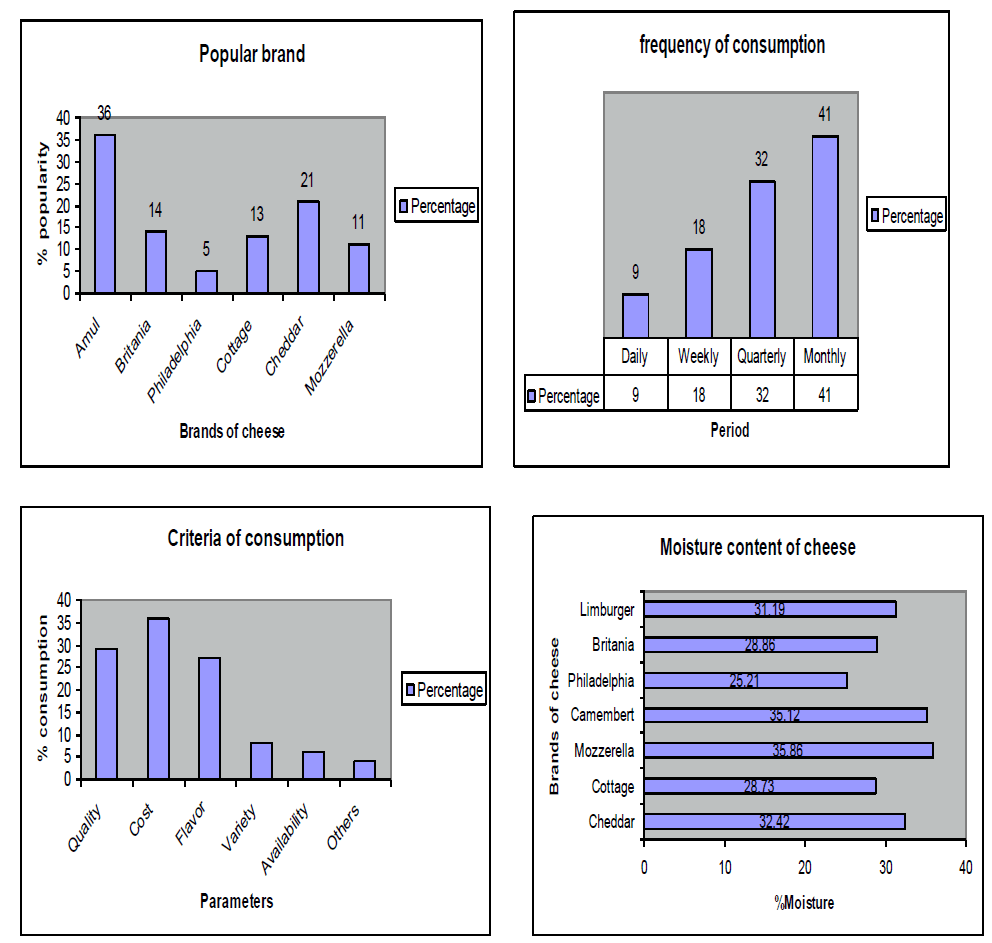

The survey reveals that Amul brand is most popular amongst the consumer. Also the criteria for the selection of particular brand of cheese are much more dependent on the cost involved for the purchase. The study also reveals that sometime particular brand of cheese is not available may be due to low market demand. However, frequency of consumption is very low indicating that consumers are not aware of nutritional advantages of the cheese and its consumption is strongly related to the cost factor. Most of the families use cheese for garnishing purpose out of fashion and consume cheese as a delicious food ingredient.

Nutrients in cheese

Cheese is a concentrated dairy product made from milk curds and has been consumed as part of the human diet. Alike Milk, yogurt and other dairy products, cheese contains many nutrients including calcium, phosphorous, protein, fat soluble vitamins and B vitamins. Cheese serves as an excellent source of milk fat and proteins. It is a rich source of fat soluble vitamins like A, D, E and K. Apart from serving as an important source of minerals calcium and phosphorous, it is concentrated in energy; Cheese is both palatable and easily digestible.

Protein, 31.23% Fat, 34.39% Water, 30.17% Mineral matter, 4.31%

Microbial status of the cheese [12]

Each brand of cheese was examined for the yeast and mold count to determine the shelf life.. The moisture content has a positive effect on the results of such investigation. Hence moisture of cheese was also determined by titrimetric method. The results are tabulated in the table 4.

It can be seen that moisture content is greater degree of variation which can be attributed to the synthesis strategies employed in manufacturing. It is documented that lower moisture content can increase the shelf life of the cheese but has lesser acceptance value due to hardness of the product. The yeast, mold and coliform counts are almost identical in each brand of cheese. This may be due to the strict PFA act in particular with the cheese. All the producers follow the rules strictly since it is the most essential parameter for cheese.

Up-gradation of nutritional value [15-16]

The various brands of cheese take their names from the places where made. Many foreign ones are now well imitated in this country. The favorite kinds of skim-milk cheese are: Edam, Gruyère, and Parmesan. Parmesan is very hard and used principally for grating. The holes in Gruyère are due to aeration. The favorite kinds of milk cheese are: Gloucester, Cheshire, Cheddar, and Gorgonzola; Milk and Cream cheese: Stilton and Double Gloucester; Cream cheese: Brie, Neuf-chatel, and Camembert.

Cheese is the solid part of sweet milk obtained by heating milk and coagulating it by means of rennet or an acid. Rennet is an infusion made from prepared inner membrane of the fourth stomach of the calf. The curd is salted and subjected to pressure. Cheese is made from skim milk, milk plus cream, or cream. Cheese is kept for a longer or shorter time, according to the kind, that fermentation or decomposition may take place. This is called ripening. Some cream cheeses are not allowed to ripen. Milk from Jersey and Guernsey cows yields the largest amount of cheese. Cheese is rich in protein and can be used as a substitute for meat. Cheese in the raw state is difficult of digestion. A small piece of rich cheese is often eaten to assist digestion.

Cheese is a concentrated source of many nutrients in milk. During the usual cheese making process, the water insoluble components milk protein - casein and fat, remain in the curd and the water soluble constituents e.g. carbohydrates, salts, and proteins smaller than casein, remain in the whey. The amount of various nutrients retained in the curd and whey depends on the type of cheese manufactured, the type of milk used and the manner of coagulation. The enzymes and bacteria involved in ripening of each specific kind of cheese may alter the nutrient content of the end product. A 113-g serving of 4% fat product has about 120 calories, 5 g fat (3 g saturated), 3 g carbohydrates, and 14 g protein. It contains about 500 mg sodium, 70 mg calcium and 20 mg cholesterol. Some manufacturers produce low-fat and nonfat varieties. A fat-free kind of a similar serving size has 80 calories, 0 g fat (0 g saturated), 6 g carbohydrates, and 14 g protein. To compensate for the flavor missing from the fat, low-fat and nonfat ones tend to have more sugar in them. Very low sodium varieties are also produced, and can be salted to taste. Cottage cheese is popular among dieters and some health food devotees. It is a favorite food among bodybuilders, runners, and weightlifters for its high content of casein protein while being relatively low in fat. Pregnant women are advised that cottage cheese is safe to eat during their pregnancy, whereas some cheese products are not.

A new variety of cheese was developed with better fatty acid composition which will meet the advantages of essential fatty acid. The nutrient profile of newly synthesized cheese as tabulated in table 3. It indicates the improved value of fatty acid content and rich in minerals like Ca and P. The composition of cheese is more beneficial to athalets and sports persons.

The new cheese product was examined for the yeast, mold and coliform count. Also the moisture determination found was averaged at 30.54% which is within the recommended value for the cheese. The lower % moisture and microbial count indicates that newly synthesized cheese has better shelf life.

The Amul brand of cheese was popular amongst the consumer even though it has marginal higher cost. The cheese is more frequently consumed mainly for the garnishing the food variety. It is also evident from the chemical analysis that newly synthesized cheese has better composition with respect to fatty acid mineral content. The increased value of calcium and phosphorus are essential for the better health bone. However, it has increased amount of sodium which may have adverse effect on the health. It is recommended to investigate the product for detailed fatty acid composition.